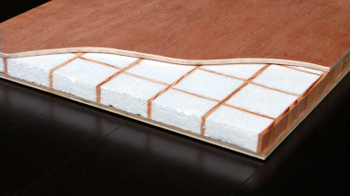

What Are Sing Lightweight Honeycomb Panels?Sing Honeycomb is a sandwich panel composite material with built in structural grids. Our grids are made of vertical grain renewable veneer wood fiber, and foam. We construct our Singcore in a fashion similar to torsion box technology most commonly found in the airplane industry. This technology is what allows our panels remain strong, lightweight, and flat without denting, cracking, and warping. See a comparison here. Inventor Peter Sing uses this torsion box technology, along with wood fiber and foam to create patented Sing Honeycomb: the incredibly strong, true flat, lightweight, renewable “true green” composite material of the future. Check out our products section to see a few different applications. The Sing Core is based on primitive torsion box honeycomb designs, but is exponentially improved upon the basic design. Sing Core is manufactured with LESS

Our unique manufacturing process requires LESS

Sing Core panels are

That is why the supplier of high-end custom-built oversize products to the

has sought out Sing Core as their solution. Yet, we make this technology affordable, even to compete with cheap imports. If you are currently importing substandard plywood from off-shore, shouldn’t you think about being proud to say, “Made in the USA,” reducing your costs, delivery times and providing your clients with a superior product that is not only eco-friendly but “true green”? Spend Less Get More With Sing Core |

|

|

Singcore Core Structure The secret of the Sing Honeycomb panel is in the Singcore. Our Singcore utilizes torsion box sandwich core technology to ensure strength, and allow our product to be lightweight. |

|

True Flat Sing Honeycomb sandwich panels utilize torsion box strength technology in order to ensure flatness. |

|

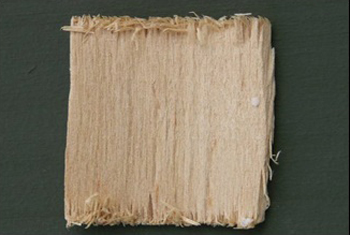

Vertical Grain Wood Fiber The heart of soul of Sing Honeycomb is in our patented Singcore invention. The core utilizes renewable vertical grain wood fiber and foam, to create our strong, lightweight, composite material. |

|

Strength Sing Honeycomb is stronger than solid wood, plastic, metal, glass, brick, and concrete in terms of lbs. per lbs comparison. |

|

Lightweight Sing Honeycomb sandwich panels are strong, flat, and lightweight. A 4’ x 8’ x 1 ½” panel with 1/8 “ Luan skins, and solid wood edging weighs in at about 55 lbs. A standard sheet of plywood weighs in at about 96 lbs. |

|

Rot Resistant Even without coating, Sing Honeycomb sandwich panels outlast plywood, solid wood, MDF, and particle board. Plywood and engineered wood rot crack because of the weak glue layers. Sing Honeycomb panels last because underneath the skins lie Singcore, which keeps the panels flat through torsion box technology, and therefore doesn’t allow the panel to crack. |