Sing Sandwich and Sing Panel are the world’s most advanced rigid insulation panel system utilizing patented Sing Core as the insulated reinforced torsion box structure which is the green building solution that is lighter in weight and stronger than steel (660 PSI) pound-for-pound.

Thermal Insulation R Value

Thermal Insulation R Value

Customers using Sing insulated plywood get to choose the R value that best suits their application. Standard rigid insulation R value is 3.5 per inch but can be upgraded to R 6.5 per inch. You determine the degree of thermal insulation required by your project, then customize your Sing panel’s thickness to achieve the results you desire based on your specifications.

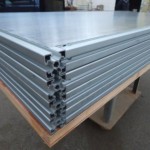

Insulated Wall Panels

Sing Insulated plywood comes pre-constructed to be used as free standing insulated walls right out of the box. In many cases, builders who embrace Eco-friendly insulated Sing technology take full advantage of the natural reinforced torsion box structure to build structures that are completely frameless.

That’s right; Sing Panels are so strong that you can build enormous structures without the need for complicated framing structures, because the structure is built into the rigid insulated panels themselves making Sing Core’s insulated plywood one of the most advanced insulation materials that is expanding the imaginations of architects and engineers all around the world.

Insulation for Walls

Certainly, there is no need to use additional insulation if you’re building your structure with Sing insulated plywood exclusively; but if you are shearing up the thermal insulation of a pre-existing structure, then Sing’s rigid insulation solution is right on track for a fast, long lasting solution for quickly and easily adding both strength and insulation in one easy step.

Certainly, there is no need to use additional insulation if you’re building your structure with Sing insulated plywood exclusively; but if you are shearing up the thermal insulation of a pre-existing structure, then Sing’s rigid insulation solution is right on track for a fast, long lasting solution for quickly and easily adding both strength and insulation in one easy step.

That’s why Sing insulated plywood is a highly sought after material for insulating and reinforcing basements and attics giving the designer or do-it-yourselfer 100 percent control over the wall insulation value and installing insulated interior wall panels has never been easier.

Insulation Boards

Because Sing insulated plywood can be custom specified, many builders are choosing to have their rigis Sing insulation materials pre-configured into insulation boards in 16” x 24” or 24” x 96” sizes to accommodate their building styles, increasing production time, dimensional stability and longevity over time.

One nice thing about Sing’s rigid insulation board, is that you can have them any way you want them; any length, any width, any thickness and more amazingly – Any Available Surface Material – for the most versatile insulated wall board available.

Insulated Plywood

Insulation Boards