America’s premier Insulated Aluminum Panels are lightweight, high strength, and have insulation R value that is variable to meet your project’s requirements and can be guaranteed to be fail-free for 50 years all thanks to having patented Sing Core inside. No other insulated aluminum panel can compare to Sing Core’s premium strength (660 PSI), high precision (+/- .006 inch) and high performance (full 50 year warp-free and structural guarantee) making them the best architectural insulated aluminum panels made in the USA.

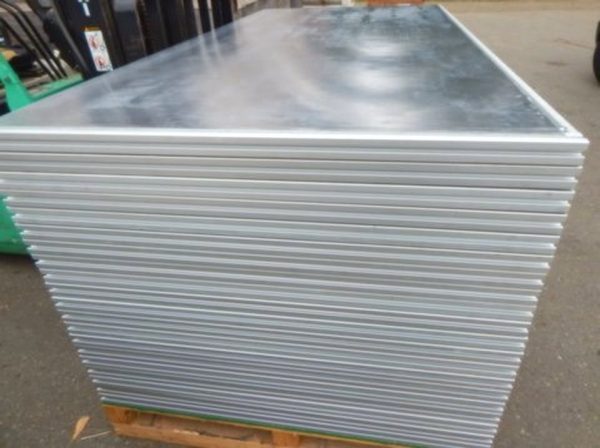

Low Cost 4’x8′ Aluminum and 4’x10′ Honeycomb Structural Panels

Our low cost, standard sized 4’x8′ and 4’x10′ aluminum panels cannot be beat in terms of price and value. While maintaining all the strength, durability, and longevity of our more expensive custom panels, these mass produced variety can be had for a fraction of the price.

Our low cost, standard sized 4’x8′ and 4’x10′ aluminum panels cannot be beat in terms of price and value. While maintaining all the strength, durability, and longevity of our more expensive custom panels, these mass produced variety can be had for a fraction of the price.

Previously thought impossible, thanks to great steps forward in manufacturing prowess, mass produced Sing Core aluminum honeycomb panels are flooding the market!

Now Click for Price for a 4’x8′ panel.

| Size | Sqft |

|---|---|

| 4’x8′ | 32sqft |

| 4’x10′ | 40sqft |

| over 4’x10′ | any size |

Patented Insulated Aluminum Panels

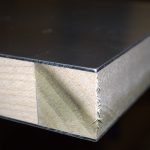

Our patented insulated aluminum panels are a composite reinforced structural insulated panel (RSIP) not to be confused with a standard SIP panel, which is not as structurally sound as the Sing Core Reinforced SIP. The secret is that all Sing Core RSIPs feature patented Sing Core inside, which is a torsion box/rigid foam insulation hybrid structural core imbuing these insulated aluminum panels with their unprecedented strength, tested independently to be able to withstand stress upwards of 660 PSI, high precision and performance.

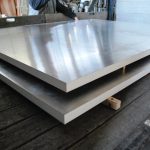

Architectural Insulated Aluminum Panels

Sing Core insulated aluminum panels are not an off-the-shelf generic product. Every architectural insulated aluminum panel is custom manufactured to architectural specifications in any size, length, width and thickness. Starting at R3.5 per inch the rigid foam insulation can be exchanged to increase insulation R value to meet your specifications and aluminum exteriors are available in any standard colors or can be custom painted or finished.

Aluminum Shelf, Raised Floor for Mercedes Van

You could use Sing Core aluminum panels inside your private or commercial vehicles to make ease of accessing and organizing cargo, as aluminum shelves, or as aluminum raised flooring.

Pictures (above) depict inside of van project for increasing ability to handle and sort cargo in transit.

For more information about James Abke’s Mercedes portable home van conversion, see it here: http://singcore.com/news/sing-core-and-james-abke-turn-mercedes-van-into-portable-home.

Metal Wall

One of the most popular applications for Sing insulated aluminum panels is used in energy efficient metal wall projects including metal storefronts, aluminum in-fill panels and aluminum glazing panels. These architectural insulated aluminum panels are custom manufactured to your architectural specification in terms of panel size (up to 50 ft. in length) and can feature any available painted and anodized colors for maximum visual impact, whether utilized in interior or exterior metal wall applications.

Insulated Wall Panels

Sing insulated aluminum panels can be found in high end architectural, commercial, industrial and cold storage markets where high precision and performance are second to none and the end users demand only the very best Eco-friendly building materials. The insulation is customizable giving you complete control of wall insulation R value which improves moisture, temperature and environmental conditions while also adding sound deadening characteristics.

Building Envelopes

Commercial projects using Sing Core insulated aluminum panels as part of the exterior building envelope are not restricted by adhering to a standard product as every metal building insulation panel is custom built in our Pacific Northwest factory to architectural specifications. This allows unbridled creativity and design freedom as panels are nor restricted by size, shape or thickness. Whether your project is a high-tech renovation or an exclusive high-rise project, Sing Core can supply the insulated panels to match your specs. Be aware, since we do not build a standard product, we do not have an engineer-stamped and approved panel, so the project’s engineering staff will be responsible for approval and rating any Sing Core insulated metal building products.

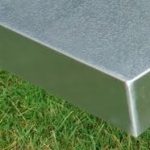

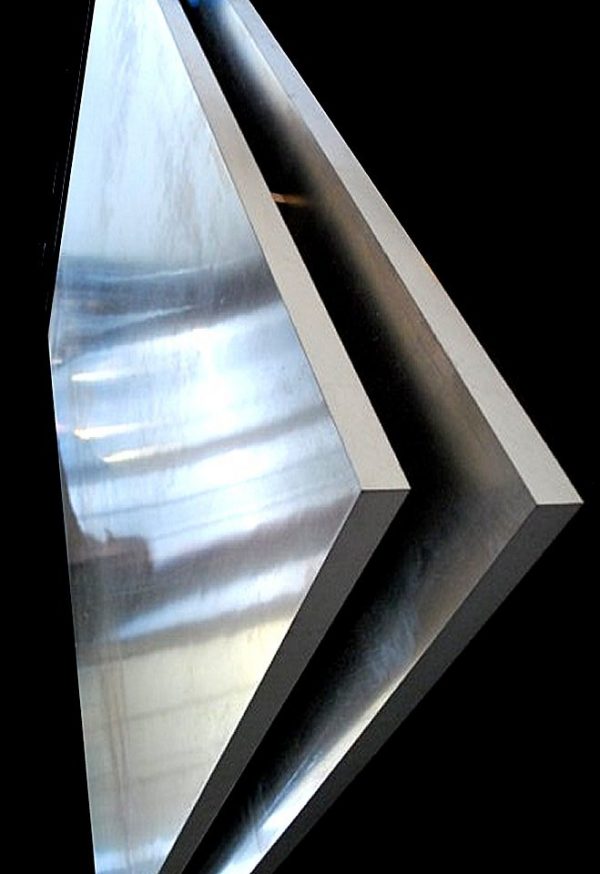

High Precision

Advantages of Sing Core’s high precision (+/- .006 in.) and high performance (low maintenance and warp resistance) include maintaining a structurally sound uncompromised airtight seal. This is especially advantageous when maintaining a sustainable energy efficient structure or clean room, whether as a permanent installation or modular portable structure.

We have the best precision of any manufacturer in the world. No one can come close to our methods of manufacturing the most precise, dimension-ally stable panels. This is called “mission impossible.” No one else can do this!

Trade Professionals

Serving architectural, commercial, industrial and institutional markets, Sing insulated aluminum panels are patented source building material available to architects for specification in projects serving the most discriminating clientele, contractor, metal fabricators and millworks throughout the United States and abroad. Architects and other high end professionals choose our panels because they have come to expect quality and unbeatable strength and light weight nature. Our panels beat the competition by miles. No one else can make insulated aluminum panels as straight, high strength, and warp free as ours.

- Aluminum metal doors strength test