Many people, who stick their toe in the water of the Tiny House movement, are lulled by the inexpensive option(s) associated with living affordably in a structure that is a fraction of the square footage of a larger home. To some this makes perfect sense and is an Eco-friendly approach to living more simply for a better future.

Many people, who stick their toe in the water of the Tiny House movement, are lulled by the inexpensive option(s) associated with living affordably in a structure that is a fraction of the square footage of a larger home. To some this makes perfect sense and is an Eco-friendly approach to living more simply for a better future.

WARNING

Be forewarned: Contrary to the perception of uneducated or inexperienced potential Tiny House builders, the costs associated with building a Tiny House might be more than expected. In fact, the cost per square foot can be much more than a traditional home.

Initial costs aside, a Tiny House is still an excellent option to reduce regular monthly expenses, using less energy, reducing your carbon footprint and living a more sustainable life for the future of all earth’s creatures.

GOOD NEWS

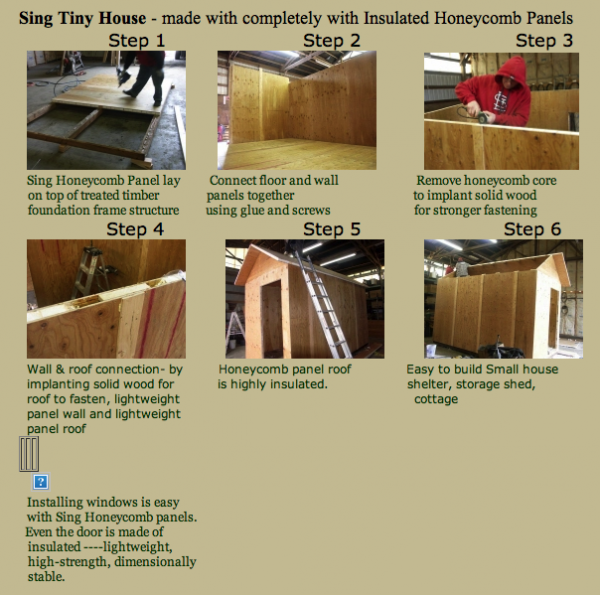

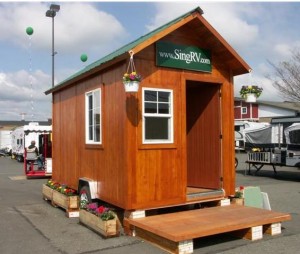

One company helps the most earth-conscious Tiny House builder to build an upscale, high-end Tiny House that outperforms the standard Tiny House fare. The company, Sing Core, provides lightweight, high-strength panels that can be quickly and easily assembled.

Tiny House on Wheels side-by-side comparison:

Let’s look at two identical Tiny Houses; one built with traditional materials, and one using patented Sing Core construction.

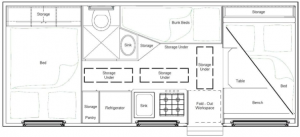

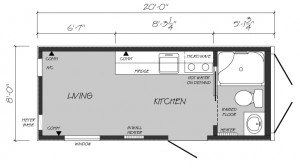

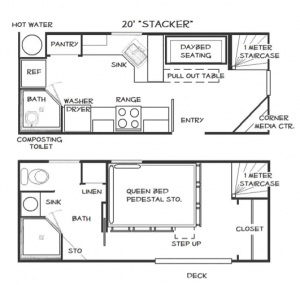

Both 130 square feet Tiny Houses are built on identical 18 ft. trailers, and feature:

A 19 ft. x 8 ft. footprint, 6 ft. x 3 ft. bathrooms, lofts and a road height of 13’ 5”

| Traditional Tiny House Ceiling height: 6′ 3″ Loft height: 3′ 8″ Weight: ~5600 lbs. |

Sing Tiny House Ceiling Height 6’ 8” Loft Height: 4’ Weight: ~2600 lbs. |

Pre-fabricated Insulated Structural Walls

In comparison, the unique attributes of patented Sing sandwich panels are pre-fabricated walls with exterior on one-side and interior on the other.

Go Frameless

No frame is needed to build the Sing Tiny House. All the structure and insulation is already built into the wall.  In fact, even though patented Sing Core is featured in the most exclusive Tiny Houses, Sing Core does not design or build Tiny Houses. Sing Core only supplies the lightweight, high-strength, pre-insulated panels to your favorite lumber yard.

In fact, even though patented Sing Core is featured in the most exclusive Tiny Houses, Sing Core does not design or build Tiny Houses. Sing Core only supplies the lightweight, high-strength, pre-insulated panels to your favorite lumber yard.

Expense?

Granted, Sing Sandwich panels are more expensive than standard 2×4 or 2×6 frame but the results are outstanding resulting in a more truer green long-term solution to Tiny House living. Due to the added expense Sing sandwich panels are primarily used in upscale, high-end Tiny House designs.

Experimentation Encouraged

Sing Core does not have an R&D department specializing in the Tiny House industry, but they do actively support Tiny House enthusiasts who desire to take their innovative Tiny House concepts to the next level and make them available to the Tiny House community at large.

What is the Next Level?

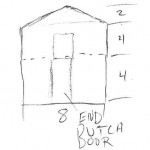

Who knows what the next new breakthrough design might be. Sing Core is currently running a national Folding Modular Tiny House Competition inviting Tiny House builders to use Sing Sandwich panels to create collapsible homes; like this folding house idea video:

Other ideas include the expandable custom slide-outs featured in Jay Oistead’s Ragsdale Tiny House video:

Let Your Creativity Run Wild!

Even though Sign Core only supplies their Sing Sandwich panels to lumber yards for distribution, they do have a marketing division that encourages experimentation with Sing Sandwich panels. Reviewed on a case-by-case basis, they may partially subsidize your creative genius in exchange for documentation of your project.

If you new idea warrants, Sing Core will also help promote your idea and possibly partner with you to support you in taking your design to the masses.

Your idea is likely to be accepted if you have a unique proposition that can take advantage Sing Core’s extraordinary attributes of being pre-insulated, sound-deadening, lightweight, high-strength and Eco-friendly.

Addressing the Challenges

For most Tiny House builders, the Tiny House building process can be daunting. For instance, see this video that depicts the time-lapse of a Tiny House build that lasted 88 days:

As one Tiny House enthusiast requested:

I need a Tiny House that is lightweight that can be flat-packed, so that I can set it up anywhere I want… and when the inspector comes by, I can quickly and easily break it down, relocate it (if I have to) and rebuild it when and where I want (or can).

And we believe such a home should be pre-insulated, structurally sound, offer privacy, safety and security while looking spectacular while it is being enjoyed either as temporary shelter or a home.

Sing Core – and you – can make this and many other dreams come true.

Contact us if you have a Tiny House dream that we can help to bring to fruition.