Lightweight Tiny Home – Built with Sing Core

Patented Lightweight Tiny Home Technology

Lightweight Tiny Home technology. Patented Sing Panels have been trusted in many industries. They are used in home building, boat building, and even in the aircraft industry. Because they are strong and light, they are now making a big impact on any lightweight tiny home.

The Rise of the Lightweight Tiny Home

Recently, the tiny house community has started to notice these panels. Lightweight tiny homes are appearing across the United States and around the world. In many cases, they fit into the smallest spaces on existing properties. At the same time, they can be moved, transported, or even towed. In other words, they work as a portable house, a small modular home, or a tiny house on wheels.

Why Choose Sing Panels for a Tiny Home

A lightweight tiny home built with patented Sing Core is simple, functional, and elegant. The unique core makes the panels stronger and lighter than traditional building materials. As a result, tiny home builders gain many benefits, from easy construction to long-term durability.

Stronger Walls for a Lightweight Tiny Home

SingCore products, such as the Sing Sandwich and Sing Panel, use a built-in torsion box design. This unique structure gives the panels superior strength over long spans. Because of this, even the most eco-friendly builder can create a lightweight tiny home without relying on heavy 2×4 or 2×6 framing.

More Space Inside Your Tiny Home

Architecturally, removing the need for framing makes a big difference. Without bulky studs, you gain more usable space inside your small home plans. As a result, every square inch of your lightweight tiny home becomes more functional.

Thin Walls, Stronger Than 2x4s

Many Sing Tiny Houses have been built using only 1 ¼-inch thick Luan skin Sing Sandwich Panels. These walls are incredibly strong, even though they are much thinner than a standard 2×4 wall. A typical 2×4 wall is at least 4.5 inches thick, which wastes over 3 inches of precious space. In contrast, a 1.25-inch Sing Panel wall is thinner, lighter, and stronger.

High-Strength, Frameless Design

Even loft beams and roof structures can be supported by frameless 1 ¼-inch Sing Sandwich Panels. That level of strength is rarely found in traditional building materials. Therefore, a lightweight tiny home built with Sing Panels is not only efficient but also built to last.

Ready for a Tiny Home quote?

CLICK HERE to get an estimate TODAY

Space-Age Technology for Lightweight Tiny Homes

What makes patented SingCore products different from all other building materials is the unique composite design. The panels combine an improved wood torsion box structure, recycled foam, and strong surface materials. As a result, the performance is unlike anything else in the building world.

Built for Strength and Efficiency

SingCore outperforms other composites used in aerospace and marine industries. It delivers lightweight strength while staying eco-friendly. Because of this, a lightweight tiny home built with SingCore can withstand extreme weather and high winds without compromise.

Why Choose SingCore for Your Lightweight Tiny Home?

1 – More Usable Space

When building a small home, every inch matters. SingCore panels create 1.25-inch walls instead of bulky 4.5-inch framed walls. Therefore, you get more living space inside your lightweight tiny home.

2 – High Strength

SingCore is more rigid and stronger than traditional materials. In fact, Washington State University tested it at 660 PSI, which is stronger than steel pound for pound. This gives your tiny home incredible durability.

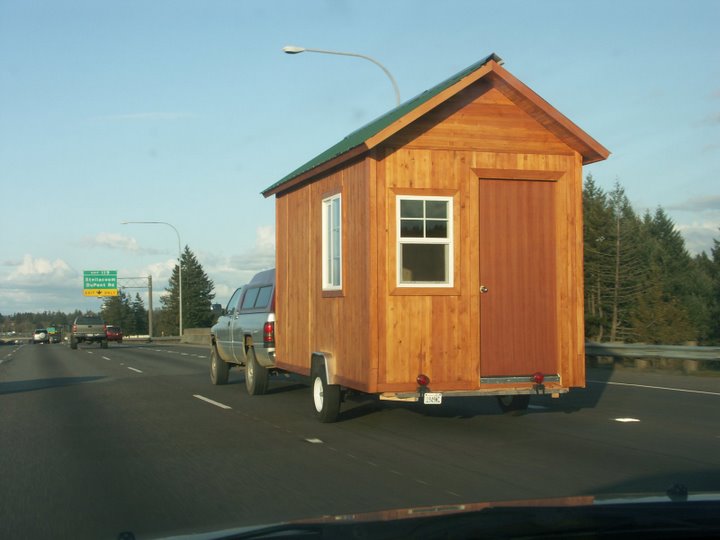

3 – Lightweight Tiny Home Design

A lightweight tiny home built with SingCore is about half the weight of a standard tiny home. For example, a Sing Tiny House weighs only 2,600 pounds compared to a typical 5,000-pound build. As a result, towing is easier and safer.

4 – Built-In Insulated Tiny Homes

Our pre-insulated panels save time and cost. Each panel achieves up to 6.5 R-value per square inch. This means your lightweight tiny home stays warm in the winter and cool in the summer.

5 – Custom Tiny Home Choices

Every homeowner wants something different. That is why SingCore panels can be finished with almost any surface, including wood, plywood, aluminum, cement board, or metal. Because of this, your lightweight tiny home can match your personal style.

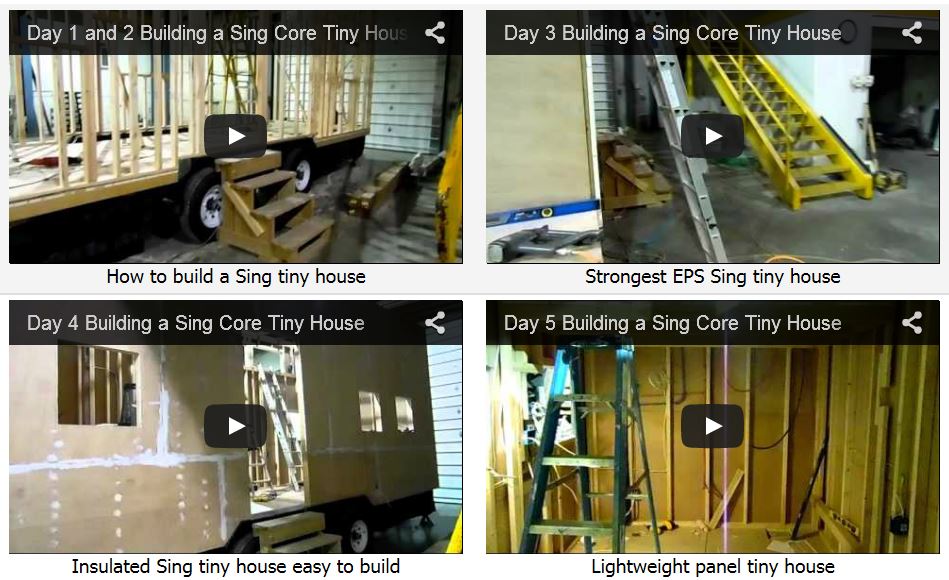

6 – Easy to Build Tiny Homes

Building with SingCore is fast. A complete set of floors, walls, and roof panels can be assembled in only three and a half hours. Even a first-time DIY builder can finish in just a couple of days. After that, finish work takes only a few weeks, depending on the design.

Lightweight Tiny Home Functionality

If you are not handy, you can still enjoy the benefits of a lightweight tiny home. Simply hire a local woodworker or contractor. The key is to work with someone open-minded and willing to embrace this innovative building method. On the other hand, if you are willing to learn, almost anyone can build a Sing Tiny House with patience and basic tools.

How to Use a Lightweight Tiny Home

Lightweight tiny homes are flexible and practical. It is common to see them in RV parks or on the road as recreational vehicles. They also make great vacation homes. In addition, they are perfect as auxiliary living spaces. You can use one as a guest house, a private bedroom, a mother-in-law suite, or even student housing. Furthermore, a lightweight tiny home can serve as a portable office, an art studio, or a music space.

Simple Ways to Connect Panels

Assembling a lightweight tiny home is easier than most people think. There are several ways to connect SingCore panels. Some builders choose pre-installed cam locks, which are especially useful if the house may need to be disassembled later. Others rely on traditional screws or nails. However, we recommend urethane-glued assembly because it is stronger and more durable than other methods.

Proven Speed and Strength

To see how simple the process can be, watch a 70-foot trade show display (with two office areas) built in just 47 minutes by one person who had never done it before. This shows how strong and efficient a lightweight tiny home can be when built with SingCore.

|

Making Lightweight Tiny Homes Even Easier

SingCore makes the assembly process quick and simple. For example, we can pre-install windows and doors directly into the panels. This means your lightweight tiny home arrives ready to put together, saving you time and effort.

Versatile Uses for Sing Panels

Sing Tiny House Sandwich Core Panels are not just for homes. They are perfect for many small structures. You can use them for wood sheds, guest houses, or utility sheds. In addition, they work well for studios, ticket booths, pump houses, or disaster relief shelters. They even make excellent playhouses, espresso stands, or other small buildings.

Built to Travel and Last

Every panel is strong, lightweight, and beautiful. As a result, your lightweight tiny home or small structure can travel safely, assemble quickly, and provide lasting performance. With SingCore, you get both function and style in one smart solution.

FAST FLOOR ASSEMBLY

This 12 minute insulated portable stage assembly has been time lapsed to a brief 1 minute video.

Green and Eco-Friendly Lightweight Tiny Homes

A lightweight tiny home built with SingCore is designed to be environmentally responsible. Each panel uses recycled foam core, renewable veneer, and formaldehyde-free glue. Because of this, the carbon footprint is minimal. In addition, the insulation inside each panel saves energy year after year. Even the manufacturing process is efficient, with very low emissions.

Strong, Stable, and Built to Last

Sing Tiny Houses are stronger than traditional framed structures. Instead of nails, each panel is bonded with structural glue across the entire surface. This creates a tighter hold than nails ever could. As a result, thousands of nails are saved, and long-term structural integrity is guaranteed.

Sing Honeycomb Panels are built with precision down to .007 of an inch. That level of accuracy means your lightweight tiny home is always straight, smooth, and stable. Unlike nails, which can settle and crack timber over time, SingCore panels stay bonded and resist warping for years. By choosing Sing Panels, you help preserve the environment with a high-quality, long-lasting building solution.

Proven Structural Benefits

-

Compression strength up to 660 PSI

-

Resistant to dents and dings

-

Rigid, straight, and stable over time

Custom Lightweight Tiny Home

Beauty with Fewer Seams

SingCore also adds beauty to your lightweight tiny home. Because we make large panels in sizes like 4’x8’ and 4’x10’, your home will have fewer seams. This creates a smooth, clean finish. The surface can be covered with many different skins, from rustic wood to sleek metal, allowing you to match any style.

Skin Options Include:

-

Aluminum

-

Galvanized Metal

-

Stainless Steel

-

Marine-Grade Plywood

-

Standard Plywood

-

Douglas Fir

-

Birch/Luan

-

Cedar

(Specialty orders are also available.)

How We Ship Your Panels

We ship by freight and use a broker to find the best price and safest route. This ensures your panels arrive on time and in perfect condition, ready to assemble into your lightweight tiny home.

The Cost to Build a Lightweight Tiny Home

At first, Sing Sandwich and Sing Panels may seem more expensive than standard plywood. However, the comparison changes when you add up all the costs of traditional building. With framing, insulation, plywood, interior and exterior facings, plus the extra labor and equipment, the old way ends up costing more. In contrast, the Sing solution saves time, reduces materials, and delivers unmatched benefits. For this reason, building a lightweight tiny home with SingCore is the smarter long-term investment.

See more of what Sing Core’s panels can do HERE.

- Mobile Storage Units

- Beach House Getaway