- Completed Big Pivot Fire Doors

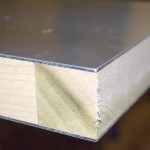

- Lightweight honeycomb wood door

- Insulated wood door panel

- Super lightweight super strong wood door panel

- Lightweight large honeycomb door panel

- Insulated sing sandwich door panel

- Patented sandwich panel

- Super strong wood door panel

- Sing honeycomb strong panel

- Sandwich lightweight door

- Durable honeycomb sandwich panel

- Strong patented wood panel

- Sing honeycomb wood door panel

- Lightweight insulated honeycomb door panel

- Patented strong lightweight panel

- Unfinished lightweight honeycomb panel

- Lightweight non warping honeycomb door

- Super strong insulated door panel

- Honeycomb sandwich lightweight door panels

- Strong lightweight honeycomb door

- Non warping strong wood panel

- Super strong wood door core

- Large white oak pivot door

- 14 ft. x 6.5 ft. warp free white oak

- Non-warping oak pivot door

- Sing Panel True Flat Pivot Door Panel

- Lightweight easy handling

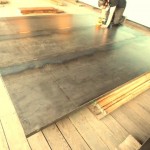

- CNC ready to finish

- Near seamless oversize

- Sing Panels for Pivot Doors Being Shipped

- Super strong pivot wood door

- Sing Panel Pivot Door

- Lightweight honeycomb door

- Sing Panel Exterior Pivot Door

- Insulated non warp weatherproof door

- Sing Panel Interior Pivot Door

- Large lightweight honeycomb entry door

- Sing Panel Wood-Skinned Pivot Door

- Sing Panel Room-Dividing Pivot Door

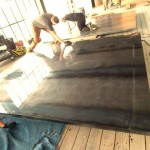

- Skinning wood panel with vacuum bag

- Sing roofing wood frame

- Sing Core White Oak Pivot Door Panel

- Sing Panel for a Pivot Door

- Shipping Sing Panels for Pivot Doors

- Unfinished Sing Panel for a Pivot Door

- Sing Panel Strength

- Sing Panel Commercial PIvot Doors

- Sing Panel Wood-Skinned Pivot Door Panels

- Sing Core Oversized Pivot Door Panel

- Sing Core Panel True Flat Strength

- Insulated, moisture resistant, sandwich door panel

- Insulated Sing honeycomb door panel

- Lightweight, high strength honeycomb door panel

- Moisture resistance, lightweight, honeycomb door panel

- Chemical resistance, lightweight, door panel

- Large extreme edge pivot door with man door access