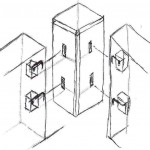

Sing Core is proud to partner with Norse to provide rapid Sing Panel connection methods that are quick and easy to assemble and disassemble for fast set up and tear down. Easier than turning a screw.

In many cases, for instance, standard 4×8 panels can be nailed, glued or channel-joined quickly and easily with satisfactory results.

In many cases, for instance, standard 4×8 panels can be nailed, glued or channel-joined quickly and easily with satisfactory results.

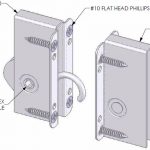

Other options for fastening panels may include cam locks (see examples left and right) that can be pre-installed, making assembly and joining easy and more secure.

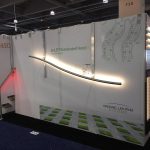

The Sing cam-lock panel solution is a high-demand solution for panels that are routinely assembled and disassembled, especially in moveable walls, trade show booths, and various wall cladding applications.

Why Sing Panels and Norse Latches?

Sing Panels weigh a fraction of the weight of stick frame walls, plus they will stand straight and remain true flat along the entire projects. If you torque a cam locked series of wall panels made any other way, you could break the cam locks with heavy panels compromising the entire structure.

High Precision

With the extremely high precision of patented Sing Core (within .006 inch) you can build the most high precision wall system and connect them securely with Norse Latches.

Norse Cam Locks in SingCore Trade Show Panels

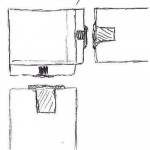

- Align the Panels

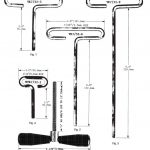

Place the two panels edge-to-edge so the latch side (with the hook) lines up with the receiver side. - Insert a Hex Key

Each latch has an opening for a 7/32″ hex key (Allen key) or T-handle. Please provide your own tool, as it is not included. - Turn to Engage

Rotate the hex key clockwise. This swings the hook on the latch into the receiver on the adjoining panel. Continue turning until the panels are snug. Do not overtighten. - Check the Connection

Once engaged, the two panels will be tightly locked together, with no gap at the seam. If they seem loose the cam lock is not fastened correctly. - To Disconnect

Insert the hex key again and rotate counterclockwise until the hook clears the receiver. Pull the panels apart gently

Stronger than Steel

Due to the patented insulated torsion box composite core, Sing panels have a compression strength of 660 PSI; that’s stronger than steel pound for pound.

This results in the perfect union, Sing Core and Norse Latches, to build the most effective high-precision, lightweight, high strength panel wall system.

Watch the assembly of this 70 ft. trade show display including two offices in less than an hour with the flick of a wrist.

No Special Tools for Assembly

We and our clients who use the Norse cam lock devices are so excited about being able to assemble incredibly large trade show displays in very little time without requiring skilled labor or special tools.

In fact, the only tool necessary to assemble our modular trade show display components is an Allen wrench.

All of this is possible thanks to the cam lock technology by our friends at Norse, Inc.

- TDS 115-1

- TDS 108-1

- TDS147-1