Medium-density fibreboard (MDF) is a popular material, especially because it can be precision sanded and remain very smooth which is an excellent surface area to treat, paint, or apply other materials, anything from vinyl and Masonite® to natural wood grain and metals. The upside to this material is wide open, while the downside presents a challenge.

The biggest problem with MDF is that it is not very stable or strong. The phrase we hear commonly is, “we love it, but it warps like…” (add expletive).

Patented Sing Core and our warp-free technologies enable us to provide millworks and artisans with a high end MDF surfaced material which is lightweight, high strength, and extremely dimensionally stable. Now, you, too, can have the highest grade MDF in the industry to use in your most important high precision projects without risk of failure.

This technology moves the smooth surfaced material which can easily be high precision sanded to a whole new level!

That’s why you find this revolutionary newly invented patented and patent pending warp-free technology atop the tallest building in the United States of America.

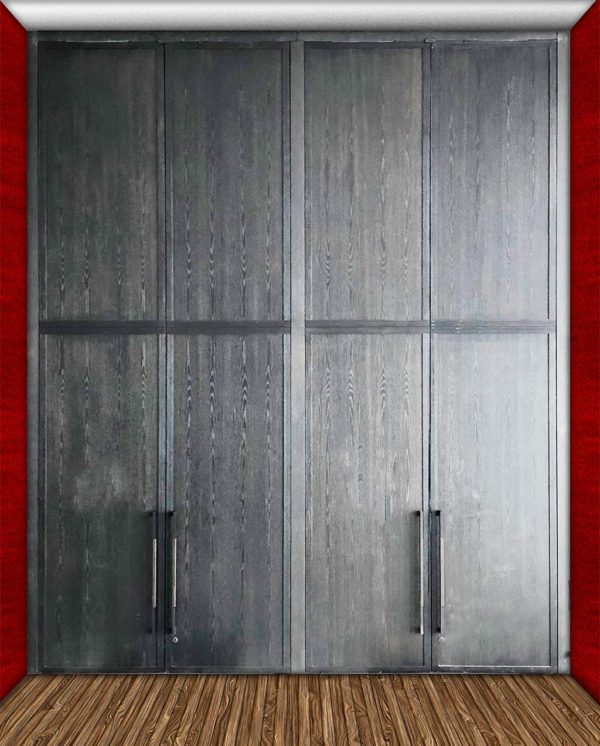

Now you can have a warp-free large MDF panel which our clients use to apply almost any laminate surface because it is so smooth, and you can even apply natural wood grain, and it can still be guaranteed not to warp, bend, twist or otherwise fail for 50 years.

Sing Core is the secret weapon used by the top millworks, large furniture designers, and the biggest and best door companies, to keep their MDF straight and true.

It is not uncommon to find Sing’s patented MDF-solution inside the most prestigious locations around the world and from beneath the sea (US Navy) to outer space (NASA) and everywhere in between.

In fact, this is the business arena where patented sing Core shines: If you have a problem keeping it straight, inventor Peter Sing’s core and his True Flat Team can provide you with a rock solid hybrid composite core covered heel to toe in MDF which can be guaranteed warp-free for 50 years.

No other Eco-friendly lightweight material can achieve such feats.

SingCore has very little deflection over a 20′ span:

Even though Sing’s patented insulation reinforced vertical grain torsion box core is often compared to honeycomb core materials, it’s plain to see that no other lightweight honeycomb core material can compare.

Whether Sing’s core is used as substrate inside panels, posts, and beams, or as warp-free door core, you will find architects, designers, and engineers empowered by having access to the most revolutionary building material which is changing the way things are made.

That solution is Sing Core MDF, the highest grade MDF in the industry today.