Wood pocket doors are similar to wood sliding doors in that they use similar sliding door hardware only a sliding pocket door disappears as it vanishes into an adjoining cavity within a wall (a pocket) and is therefore invisible when in the opened position.

Even though most wood pocket doors are interior pocket doors and not exposed to the weather, they do tend to warp due to changes in the environment which may render wood pocket doors useless and inoperable as they are not freely sliding in and out of the pocket for which they were designed.

By definition, sliding pocket doors should smoothly glide in and out of the cavity provided for storing or hiding them when not in use. Signs of malfunctioning wood pocket door would include not freely gliding, sticking, rubbing against the frame (damaging the finish), or getting stuck altogether either inside or outside the pocket.

The AIA and industry standards in the pocket door hardware manufacturers channel allow for a certain degree of warping to accommodate a wood pocket door’s potential to move according to changes in the environment. For instance, a 3-0 7-0 wood pocket door is considered straight and not warped, if it has a 1/4-inch variance in it. Anything over 1/4-inch is considered a warped pocket door.

That is to say that your pocket door contractor, builder, installer, and the hardware provider have taken all of this in account, and everything is built to accommodate this quarter-inch variance. These would not be considered high precision wood pocket sliding doors.

If you want high precision wood pocket doors, there is hope for you thanks to new patent and patent pending pocket door building technologies introduced by inventor and founder of Sing Core, the revolutionary Eco-friendly lightweight, high strength, pocket door building material that enables the biggest door manufacturers and best millworks in the world to create pocket doors of any style, shape, or size that can be

Guaranteed Warp-free for 50 Years

The only way to build an Eco-friendly, lightweight, high strength wood pocket door that can be guaranteed not to warp, bend, twist, or otherwise fail for 50 years, is if it has Sing Core inside. In fact, the biggest door companies in the world know this, and are already doing it, thanks to Sing’s core.

Wood Pocket Door Problems

It’s all about overcoming all the various challenges associated with wood pocket doors, especially if they are large oversized wood pocket doors.

We’ve already determined that keeping your pocket doors straight and true is a huge concern. In the past, the insertion of heavy material, such as a steel frame, could be built into the door to help keep it straight, or it has been assumed that heaviness was associated with strength.

Not he case with Sing’s core, which is both lightweight and stronger than steel pound for pound (independently tested at 660+ PSI). Next up you have the relatively low precision of other heavier materials, and the more you work with them the more compromised the precision is. Not so with Sing Core.

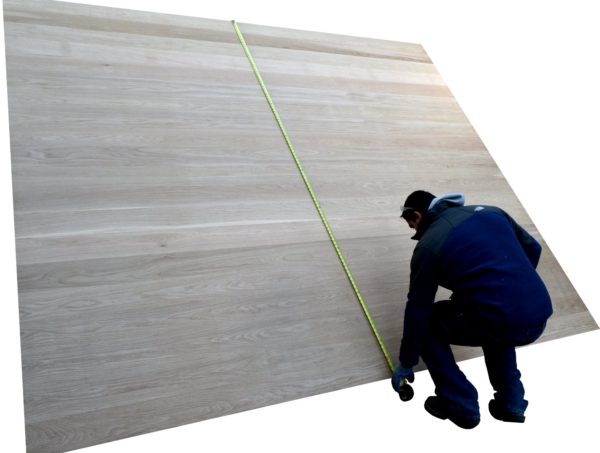

Sing Core is one of the highest precision lightweight high strength building materials in the world, sporting .006 in. tolerances.

This is how to make high precision wood pocket doors.

This is the perfect way to approach a double pocket door project, which, as you may have guessed, could present twice as many potential problems as a single prehung pocket door.

As you can see, Sing Core is an integral part of high-end pocket door construction and now you know how to build the best pocket door in the world.

Keep in mind that while Sing Core helps to build the best sliding pocket doors which provide added safety, security, privacy and superior function, your classic custom pocket door project would not be complete without utilizing an entire team to yield the best results.

High-end pocket doors are used for architectural effect, and to pull off the kinds of results exemplified by the best wood pocket doors with Sing Core inside, you will need to have the other artisans in place as well.

Sing Core does not actually make doors. What they do is to provide the biggest door companies in the world, the finest millworks, and top manufacturers of custom wood pocket doors with the best patented lightweight, high strength, fully insulated, and warp-free base doors which are used to create the one of a kind masterpieces that Sing Core is known for.

“We could not do it alone,”

says inventor, Peter Sing, whose factory only supplies the basics to others who turn his substrate into art. And likewise, the door companies, millworks, and custom wood pocket door manufacturers admit,

“We could not do it without Sing Core.”

Because there’s no other way to build a fully sustainable lightweight, insulated, and warp-free wood pocket door, unless it has Sing Core inside.