Why Contractors Choose Sing Core

What’s the most important thing for Contractors when choosing a door?

A 50-year guarantee vs. a 1-year guarantee in the oversized door manufacturing industry.

What’s most important for Contractors when choosing a door? It’s the warranty! In the oversized door industry, Sing Core offers a 50-year guarantee compared to the typical 1-year guarantee from most manufacturers. That’s a game-changer for contractors.

“Contractors looking for a door with the best guarantee against warping, Sing Core stands out. They offer a remarkable 50-year non-warp guarantee. This applies to large pivot doors, sliding doors, and veneer doors. Their patented Sing Core technology creates lightweight, high-strength doors that resist warping, bending, and twisting, even in tough conditions. For oversized doors, Sing Core’s 50-year guarantee sets a high standard for durability.” – This is ideal for any contractors.

For Contractors, it’s What’s Inside the Door that Counts

The best door contractors deserve the best door. Doors are more than just their surface. Sing Core focuses on what’s inside to deliver top performance. We supply high-end door panels to some of the world’s biggest door companies and architectural firms. Our technology solves the issues with large custom and specialty doors, like warping or loss of strength.

The secret? Our core technology. It creates high-quality, large doors that won’t warp. These doors are strong, lightweight, insulated, and sound-deadening. Want to know if a door won’t warp? Just look for the warp-free guarantee!

How You Know Sing Core is the Best

Sing Core is made of 90% foam and 10% natural vertical grain wood fiber. This honeycomb structural design creates an incredibly strong, lightweight door. It’s dimensionally stable, offers insulation, and deadens sound.

Other lightweight doors may collapse or delaminate with a hard kick. They don’t offer the same 50-year guarantee because they lack the strength and structure of Sing Core. Traditional wood-core doors swell with moisture, and the more wood used, the less stable the door becomes. Sing Core’s foam core eliminates that problem while still providing exceptional strength.

Contractors Comparing to Other Door Cores

Even ChatGPT agrees: Sing Core’s honeycomb urethane core outshines other cores. Aluminum cores, while strong, are often paper-thin and lack density. They can stretch or fail to bond properly, making them unsuitable for large, custom doors. Plus, aluminum doesn’t insulate or deaden sound as Sing Core does.

Other options like paper, cardboard, particleboard, and wood-based cores don’t compare either. These materials warp over time, soak up moisture, and often come with only a one to five-year warranty. But Sing Core’s technology guarantees a 50-year warp-free performance. For high-precision doors, it’s all about the core.

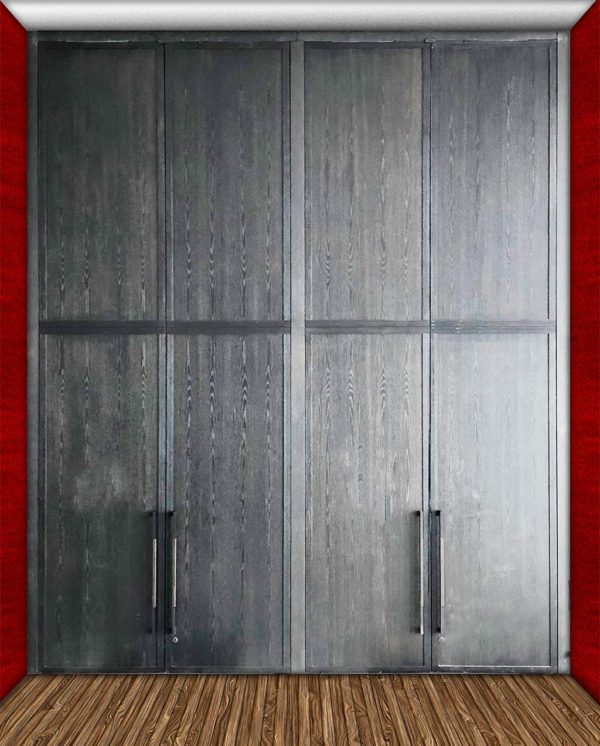

- Rift white oak pivot door

Contractors Can Trust Sing Core

Sing Core doors keep their precision, fit, and stability over time. This means fewer callbacks, fewer repairs, and fewer replacements. Our patented technology not only provides unmatched stability but also offers insulation and sound-deadening benefits. Sing Core is the all-in-one solution for contractors who need high-performance doors that last.

We’re the Right Fit for any Contractors Project

High-end doors aren’t ready-made. We collaborate with architects, millworks, and general contractors to create custom, luxury doors. Sing Core produces high-precision door panels that professionals can rely on and install with confidence.

Sing Core is Tailored to Contractors Needs

Whether large, small, pocket, or curved, Sing Core gives contractors the flexibility to bring their client’s vision to life. Our door panels come in any size or design. Contractors simply specify the dimensions and material, and we provide “Sing Core inside!”

We offer doors tailored to your specific project needs, including:

-

Large Doors: Sing Core’s patented core makes oversized doors lightweight and strong, ideal for grand entrances.

-

Small Doors: Even smaller doors benefit from Sing Core’s precision and durability.

-

Pocket Doors: The lightweight core ensures smooth operation without warping.

-

Curved Doors: Get custom curved designs without compromising on strength or stability.

Why Precision and Strength Matter for Door Contractors

Traditional doors lose stability over time. But Sing Core’s honeycomb core ensures exceptional flatness and warp resistance. This means every door remains perfectly aligned and easy to install, even in large applications. The lightweight design also reduces stress on hardware, preventing sagging.

Conclusion: Sing Core is Built to Last

For contractors who need durable, high-precision doors, Sing Core is the solution. Our 50-year warp-free guarantee ensures you’re providing your clients with the best product available. Whether you need a large pivot door or a sleek pocket door, Sing Core delivers doors that last and perform beautifully.

For doors that stand the test of time, contact us today. Visit https://singcore.com/pricing-3/get-an-estimate to get an estimate for your project.

The last thing you want on the top floor of the World Trade Center, is a warped door, and that’s why you’ll find Sing Core inside those doors.

The last thing you want on the top floor of the World Trade Center, is a warped door, and that’s why you’ll find Sing Core inside those doors.

You could find Sing Core from beneath the depths of the sea (US Navy) to outer space (NASA) and everywhere in between.

Low VOA and Warp Free

Our friends at Crestmark Architectural Millwork found SingCore to be particularly useful in large cabinet doors for the Museum of Modern Art. Our warp free oversize panels combined perfectly with the museums need for low VOA materials for archival room use.

100-YEAR FURNITURE

SingCore has been used by the Seattle AIA for their flat back style office furniture. Unlike overseas competitors, who focus on quantity of quality, or furniture panels are designed and built to last a century or more. This makes sing core the go to companion for high end yet functional furniture installations. Coming it at 1/3rd the weight of all wood panels, SingCore is extremely popular in the modular or moveable furniture space.