HPL (High Pressure Laminate), also called Formica, has often been used as counter tops, flooring, and table tops; areas that need to be tough on the surface and provide impact resistance. It has thousands of designs to choose from. The best use for HPL is large door skins, beside the applications mentioned previously.

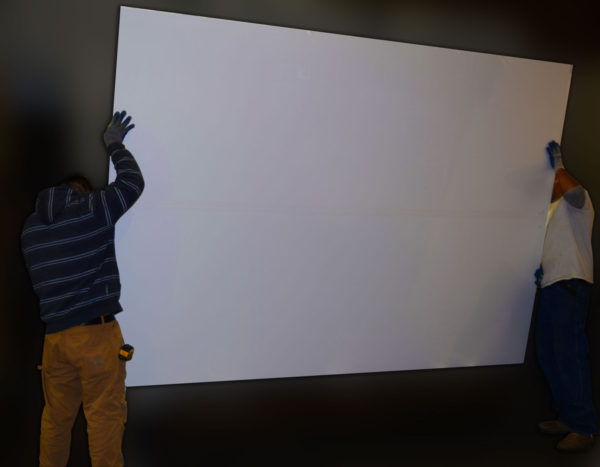

Large HPL panel with a 6′ man for reference

The reason HPL is so popularly used in commercial door applications is because it is tough to withstand heavy traffic areas, especially for school and public facility. It is difficult to damage, easy to clean, and there is a wide variety of designs available.

The substrate, or core, of HPL door panels are commonly made of MDF (Medium Density Fiberboard) or solid wood core. These materials are heavy and warp easily if it is large or very thin door panels. Heavy doors are dangerous for young children to operate. They also tend to be expensive to install due to the extra structure, hardware required, and high labor cost.

Large HPL panel before final joining with Sing Spline

Patented and patent-pending Sing core has all the advantages of HPL doors and does not have the common issues of HPL doors, such as warping or excessive weight. Sing Core provides high strength and lightweight door panels. With the unique Sing Spline, joining two panels to form a single large panel is a simple task. So if you would like to save shipping cost, or the HPL door needed is too big to fit through your doorway or inside the elevator, we have the solution for you…..click here to see pictures and video.

Large HPL panel joined with only a Sing Spline. We offer the highest level of precision at ±0.007″

Average tolerance for similar joining panels is ±0.032″

The largest HPL sliding door we have built is 12 ft. x 24 ft. x 3.5 in. thick. Despite it’s great size, it weighs less than 3 lbs. per square ft. If this door was made of MDF or particle board it could reach roughly 15 lbs. per square ft. If you have a large HPL door project, or even a standard sized HPL door, be sure to consult Sing Core. We can quote you the best price for the best quality. We use the strongest formaldehyde-free glue and the most advanced automatic gluing facility; capable of gluing 4 ft. x 8 ft. and 5 ft. x 10 ft. panels. Sing Core builds the strongest, lightweight, and warp free HPL doors panels, wall panels, ceiling panels, or table tops at an affordable price.

About HPL Laminate Doors:

Representing the upper echelon of style when it comes to affordable doors, HPL skinned doors remain at the forefront when it comes to the median between quality and affordability. To date, many architects, millworks, and contractors still don’t realize the beauty and strength offered by HPL doors, not to mention the other numerous benefits afforded by doors made with laminate skin material. When you consider the many advantages experienced when selecting HPL for your doors, it’s no wonder they have been called miracle doors by whosoever has ventured into the neighborhood of one of the greatest door skin materials ever invented.

Industrial Sliding Door, HPL skin

Factory Sliding Door, installing rain screen

Factory Sliding Door, after rain screen installation

Large Factory Sliding Door, after man door installation

12′ x 24′ x 3.5″ Factory Sliding Door

HPL doors use High-pressure laminate (HPL), which consists of several layers of core and decorative paper, are the door facing material. The underlying process of manufacturing HPL includes impregnating the paper layers with phenol and melamine resins and then they are compressed under heat. This surface material is extremely durable and is ideal for furniture and interior surfaces subject to heavy wear, such as doors in high-traffic areas in hospitality or government facilities, and as kitchen worktops.

Materials used in plastics may include acrylic, polycarbonate, multiwall polycarbonate, PETG, co-polyester, plastic laminates, phenolics, ABS, PVC, acetal, nylon, polyethylene, HDPE, UHMW, polypropylene, PTFE, & more…

For fiberglass reinforced plastic (FRP), click here

.

Advantages of HPL Door:

Ultra High Strength

HPL is broadly recognized for its high impact resistance and ability to withstand scraping and cutting of all sorts. If damaged it can be easily patched or filled and finished so it looks new. When matched with SingCore technology, HPL creates a rock solid, nearly impervious door that will give you 50+ years of rigorous service while still retaining the strength and structural stability you need to allow your doors to function under the most extreme circumstance.

Super Lightweight

Because HPL offers you an extremely strong, yet light weight door skin, when you buy HPL doors with SingCore inside, you are buying the lightest weight door on the market. Pivot doors, sliding doors, pocket doors, french doors, and man doors must be extremely light weight in order to provide you with complete, hassle free functionality over the years.

Doors using our innovative HPL skin door design function better, are lighter weight, stronger, more warp resistant, and more durable. Moreover, they come with our Signature 50 Year Guarantee and all of our products are hand made in the USA.

Enhanced Safety

For centuries, people have been using very large, heavy wood doors for their openings. They have been conditioned to desire heavy doors when it comes to high end installations. The reality is that heavy doors have many problems when it comes to safety. Elderly folks and children are much more likely to suffer strain or injury when opening a heavy door. Heavy door swing open very fast and the weight of the door can knock kids down. They can also barrel over senior citizen and pets. Heavy doors can smash fingers and break bones.

Here, at SingCore, we have solved all of the problems associated with heavy doors. Our new line of HPL doors have allowed us to make panels that have the qualities of high end doors, yet are extremely light weight, incredibly strong, and resistant to warping, twisting, skewing, breaking, and crushing.

Ease of Installation

SingCore is the home of “The One-handed Door Installation.” Because of our tested, proven method of building doors with HPL skins, we have shaved off a huge amount of excess weight from our doors. Lighter door panels means doors that are easier to transport and carry, easier for your millworks and contractors to work on, easier to install, and easier to assemble and hang. Moreover, we will install your blocking for any kind of hardware. Just tell us the blocking you need and we install it at no additional charge.

Affordable

HLP is one of the most affordable doors you can possibly buy. When you need premium doors for all occasions, HPL will meet your objective. They can be used for typical conditions, as well as, situations where you need a very high end door at a reasonable price. They are also a very good choice for situations when you need a door that can stand up to rigorous usage, but don’t have the budget for a metal door or high end wood stave door. HPL doors are also extremely strong, they provide a door skin that is very resistant to bashing, ramming, smashing, cutting, and puncture types of impact. Moreover, even if the skin is damaged, HPL doors can be easily patched. With the high strength, extremely low weight, the durability of SingCore structural core can breath life into all of your door projects.

Cost Savings

Because of our unique methods of building our HPL doors, we have been able to eliminate a lot of the material costs, as well as, the most labor intensive aspects of the process. Yet, our methods allow us to create door panels that are extremely light and strong, so your HPL door panels will be less costly overall. You will also have to buy less expensive hardware. You won’t need to replace your doors as often. There will be less damage to your door jambs, frames and the surrounding areas. Moreover, because they fit with universal door tracks and hardware, you won’t need to spend the money swapping out or upgrading door tracks. Even better, you can save money by using your existing hardware on our doors.

Visual Appeal

Among the other great advantages of HPL as a door material, they are some of the most visually appealing doors on the market. That might sound unbelievable, but there are several reasons for this. First, you can get HPL in nearly any pattern in any sheen. You can get a beautiful, authentic wood grain appearance. It comes in stone, metal, and solid color patterns. You can get matte finish, semi-gloss, or high gloss finish. You can even get an HPL door that can be painted to your own liking. We can also build you HPL doors that will give you functional surface which can act as a magnetic marker board, or dry erase finish. With HPL, the possibilities are endless. We can also put HPL of any manufacturer on your door, Formica, Wilsonart, Pionite, Panolam. We can do it all. Just ask!

You can use it as an exterior door or other outdoor applications…..

You can use it as a rain screen or even siding for weather protection.

Strong Scratch and Impact Resistance

Infiltration Resistance

Hygienic Properties; easy to sanitize.

Light Stability and UV Ray Resistance; It will not decay or fade when exposed to weather.

Stain Resistant

Easy To Clean and Maintain

High pressure laminate can replicate the appearance of any other material such as wood, natural stone, marble, granite, quartz, ceramics, and many more.

See also: Technical Information

When using a high pressure laminate material or plastic, why not take advantage of the Sing Composite strengths in your project. In this way you retain all the benefits of the material that you’re accustomed to, while having the added advantage of having unparalleled structural integrity, perfect for impact doors. Other benefits of HPL laminate doors include being insulated and eco-friendly.

Sing HPL Comparisons Based on 2″ x 2″ Grids

| Sing HPL | Foam | Aluminum | Balsawood | Nomex | Plastic | Cardboard | |

| Insulation | ✓ | ✓ | x | x | x | x | x |

| Sound Deadening | ✓ | ✓ | x | x | x | x | x |

| Lightweight | ✓ | ✓ | ✓ | ✓ | ✓ | x | x |

| Strength | ✓ | x | ✓ | ✓ | ✓ | x | x |

| Solid | ✓ | ✓ | x | ✓ | x | x | x |

| Eco-friendly | ✓ | x | x | ✓ | x | x | ✓ |

| Renewable | ✓ | x | x | ✓ | x | x | ✓ |

| Oversize | ✓ | x | x | x | x | x | x |

| Dimensionally Stable | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Affordable | ✓ | x | x | x | x | x | ✓ |

| Waterproof Upgrade? | ✓ | ✓ | ✓ | x | ✓ | ✓ | x |

| Fire Retardant Upgrade? | ✓ | ✓ | ✓ | ✓ | ✓ | x | ✓ |

| Bullet-proof Upgrade | ✓ | ✓ | x | x | x | x | x |

| Thickness Available | ✓ | x | x | x | x | x | x |

| Skin Options | ✓ | x | x | x | x | x | x |

| Easy to Machine | ✓ | x | x | x | x | x | x |

| Fast Turnaround | ✓ | x | x | x | x | x | x |

Insulation: Sing Core has built-in insulation value with a R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: Sing Core weight as much as 50% less than other materials, yet is still eco-friendly. This advanced technology that is used in the aviation industry can now be available in your home

Strength: Sing Core based on 2” x 2” grids and ¾” thick is 660 PSI. Sing Core’s superior strength comes from its advanced torsion box design.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow. Instead, they are bonded wall-to-wall with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, and is created using less energy than any other core materials with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/ or recycled material.

Oversize: Sing Core excels in large oversize products due to its unique properties and can be up to 50 ft. in length.

Dimensionally stable: Sing Core is the most dimensionally stable building material, which allows us to create large, oversized products, that are truly flat while exceeding AWI standards. Large oversized panels can be truly dimensionally stable without any warping due to temperature and moisture change.

Affordable: Even though Sing Core technology is used in high-end applications, we make it affordable to be used in a large number of applications. Sing Core performance is compared to any high-end core but could cost as little as low-end wood product cores.

Waterproof upgrade: Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements.

Fire retardant upgrade: When used in fire retardant applications, the Sing Core fire retardant door is the lightweight, super-strong, eco-friendly alternative.

Bullet-proof upgrade: In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core.

Thickness available: Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

If you want the best high pressure laminate (HPL) or plastic panel or door available make sure you use Sing Core.

Patented Sing Honeycomb HPL High Pressure Laminate panels can be any size you want; any length, any width, any thickness, up to 50 feet.

| Sing Door Strength Demo |