Sing Aluminum

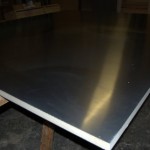

Aluminum face sheets are placed over our patented Sing core. Sing core aluminum panels are lightweight, dent resistant, and stronger than steel in inch-per-inch tests. These panels are usually used where impact is most likely to occur. Our Sing core aluminum panels are the solution for a wide range of applications that require guaranteed flat, lightweight, and rigid specifications. Other advantages of the patented Sing core honeycomb panel includes sound deadening, insulation, a stronger core, and eco-friendly.

Aluminum face sheets are placed over our patented Sing core. Sing core aluminum panels are lightweight, dent resistant, and stronger than steel in inch-per-inch tests. These panels are usually used where impact is most likely to occur. Our Sing core aluminum panels are the solution for a wide range of applications that require guaranteed flat, lightweight, and rigid specifications. Other advantages of the patented Sing core honeycomb panel includes sound deadening, insulation, a stronger core, and eco-friendly.

Custom Sizes Available

If you have a special custom, architecturally specified, or otherwise unique requirement for your project, don’t hesitate to ask. We are experts in the unexpected, and seek to exceed your every desire. Visit our pricing page for more information and to submit your price quote request.

Description

Aluminum face sheets over patented sing core. Sing core aluminum panels are lightweight, dent resistant and stronger than steel in inch-per-inch independent tests. Sing core aluminum panels are used where impact is likely to occur.

Our sing core aluminum honeycomb sandwich panels are the solution for a wide range of applications requiring guaranteed flat, light weight, and rigid specifications.

Patented Sing core aluminum panels are stronger than steel pound-for-pound, utilizing a 2×2 inch grid with our patented design and process ensures more strength in comparison to aluminum core.

Other advantages of the patented Sing core honeycomb panel includes sound deadening, built in insulation, features a stronger core and is eco-friendly.

Advantange of Sing Aluminum Panels vs. Other Aluminum Panels

| Sound Deadening | Insulated | Lightweight? | Strength to Weight Ratio |

Eco-friendly | |

| Sing Aluminum Panel | Y | Y | Y | Y | Y |

| Solid Aluminum | N | N | N | N | N |

| Aluminum Honeycomb | N | N | N | N | N |

Easy to close edge, edge banding, install solid wood implant at any location which provide stronger bonding

| Cleanroom Panels | Hurricane Panels* | Machinery Components | Instrument Enclosures | Marine | Museum Panels | PVC Coated Panels | Signage Panels | Treadplate Panels |

| Non-outgassing | Designed for | Laser staging tables | Lightweight | Marine Bulkheads | Engineered panels | chemically welded | Exterior use | Structural panels |

| non-particulating | high wind loads | support structures, | cover panels | Marine Panels | archiving artwork | for a seamless | resist wind load | safety & security |

| chemical resistant | small flying debris | fixturing platforms | X-ray equipment | durable | mounting canvases | monolithic surface | accommodate | safe walking surface |

| controlled | extreme weather | in-feed/out-feed | machined | lightweight panels | design | controlled | reflective coatings | mezzanine |

| environments | hurricane door* | tables | for attachment | corrosion resistance | gallery exhibits | environments | sign industry | high traffic |

Case study.

Aluminum out door bench.

Veneer face aluminum door.

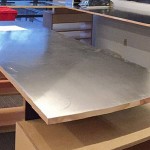

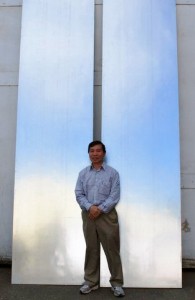

The longest, strongest, lightweight eco-friendly 37 ft x 3 ft aluminum panels shipped from Seattle to New York

|

|

Sing core aluminum panel applications include:

• Transportation – trailer, rail, marine, used in floors, walls and ceilings, cleanrooms, temporary rooms, structures, hoist access doors, high-rise construction elevator access, and barriers

Sing core aluminum structural panels offer:

• Lightweight • High strength-to-weight ratio • High moisture and corrosion resistance • Noncombustible; fire resistant • High mold and fungus resistance • High thermal conductivity

Sing Core Aluminum Panels

When applications require a lightweight, high strength composite panel, sing core aluminum panels are often the best solution. These panels are non-combustible and have high resistance to moisture, corrosion, and fungi.

Sing Core Anodized Aluminum Panels

High strength architectural soffit panels are available in a variety of finishes, thicknesses, and densities with numerous panel edge options.

Add Exterior Materials to Sing Aluminum Panels

To add exterior materials to our Aluminum faced panels.

- Make sure that the temperature is at or above 65* when gluing to an Aluminum panel.

- Take a rough sand paper and rough up the Aluminum surface.

- Clean the surface with an acetone cleaner.

- Apply a urethane glue, (Gorilla Glue) to the cleaned surface.

- Press your surface material onto the Aluminum with 30 PSI or better.

- Allow 24 hours in the press for the glue to be adhered.

Other glues may take longer. Please follow curing instructions.

Case Study: Digital Display Panels

Using Sing Core’s special invisible seam technology we are able to create extremely long or tall panels with the strength and rigidity that is unsurpassed. However, our panels are still able to be truly flat, lightweight, and strong. One such case is a video wall digital display system. This particular case specified true flat and invisaseam technologies to create aluminum panels that were about 36.5 ft long, 4 ft wide, and 2 in thick. Many clients around the world have come to realize that if you want truly flat, strong, panels that are built to last, Sing Core aluminum panels are the only solution.

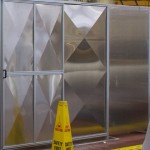

Aluminum Moveable Temporary Wall Panels

In minutes, create an office separation in any interior structure that can be easily assembled, dismantled, reconfigured, and rebuilt with minimal labor. This is because of the lightweight and high strength of these aluminum, honeycomb panels.

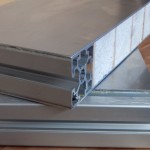

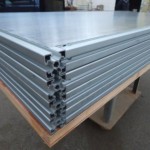

- Sing T Slot Panels

- Modular T Slot Panels

- Sound Deadening T Slot Panels

- Portable T Slot Panels

- Quick Assemble T Slot Panels

- Stronger than Steel T Slot Panels

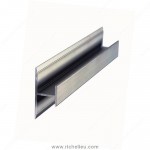

Joining With H Channel and H Molding

Embedded T-Slot Extruded Aluminum

In your choice of T1 (1 exposed slot) or T3 (3 exposed slots)

Click here for more connection methods

Sing Core Aluminum Treadplate Panels

These structural aluminum panels feature a stainless steel treadplate face for applications that require a walkable ceiling plank. They can be installed in the same manner as a ceiling tile and are available in Kevlar, epoxy, and anodized finishes on the opposite side.

Aluminum Bleacher Planks

Sing Core’s structural aluminum planks are far superior to any other aluminum bleacher planks. They are solid, lightweight, and stronger than steel pound for pound at a fraction of the price. This makes shipping to your location less expensive due to the lighter weight planks. The standard size of Sing Aluminum Planks is 9.5 in x 1.75 in x12 ft or 24 ft length. However, these planks are available in any size to fit your application. Schools can also use Sing Aluminum for locker room benches or outdoor park benches. Sing Core has been used in the following applications:

We have helped a great many people and designers overcome their complicated engineering challenges by using sing core aluminum panels as their solutions. For example, sing core has been used in the following applications:

Animal Housing Labs & Vivariums, Barricades, Clean Room Walls, Ceiling Panels, Cleanrooms, CMM Rooms, Computerized matte cutting tables, Controlled & Critical Environments, Decking, Digital X-Ray Systems, Doors, Elevators, Equipment Enclosures, Fixturing Panels, Flooring, Gangplanks, Impact Attenuation, Panels, Inspection Rooms, Interior and exterior cladding, Laboratories, Laser Rooms, Machine Components, Machine Enclosures, Manufacturing Cells, Metrology Labs, Microelectronics Manufacturing, Moveable Floors and Covers, Nano Technology, Oil Mist Enclosures, Packaging Rooms, Paint Finishing, Enclosures, Paint System Enclosures, Parts Storage & Control, Pharmaceutical Packaging, Plant Space Dividers, Powder Coating Enclosures, Reflector Panels, RV panels, Server Rooms, Shelters, Sidewalls, Signage, Specialized Doors, Sporting electronics, Storage Rooms, Telescope Mirror Covers, Temporary rooms, Truck/trailer doors, Walk Ways and Platforms, etc…

We are making a positive impact in the transportation industry by providing solutions to Marine (everything from sailing ships to luxury yachts), Railroad and railcars, Trucks and semitrailers.

Our aluminum honeycomb sandwich panels are the solution for a wide range of applications requiring flat, light weight, and rigid specifications.

Easy Ordering

All we need to know is the length, width, thickness, and your desired exterior. Custom specialty panels are made to order. To get a quote for your specialty product go to our simple online order system.

Bulk Discounts

The more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Contact us for more information.

Do It Yourself Oversize Panels

In some cases, our clients prefer to assemble two or more of our Aluminum Panels together to create their own large, oversized panels.

Here is the method that is used by our fans that are avid do-it-yourselfers:

- Seamless Video Display Panels

- lightweight true flat non warp sing honeycomb sandwich

- High precision workstations

- Retail office furnishings

- oversize lightweight high strength honeycomb door

- large oversize lightweight high strength sing sandwich door

- lightweight high strength large honeycomb door

Home -> Products -> Material Options -> Aluminum

See Also: Sing Metal Panels , Sing Cold Rolled Steel Panels, Specialty Panels

*Customer will need to perform lab tests to certify hurricane rating for local code compliance.

| Education

Material Options Technical |

Media | Links | Pricing

|