Sing Core specializes in increasing the performance, durability, and customer satisfaction in high-end veneer work in custom veneer doors of any size which can be guaranteed to remain warp-free for 50 years, including full structure warranty. No other method of manufacturing a large high-performance veneer door can achieve these results.

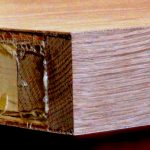

It all starts deep within the structure of any veneer door with Sing Core inside. Sing Core is the patented brainchild of inventor Peter Sing who conceived of the structure core which revolutionized the way doors were made.

Sing’s invention is basically a vertical grain torsion box core with small grid structure where the grid voids, which are usually left open in traditional torsion box, are filled with rigid foam insulation.

This composite base material is pressed between to stress skins to create Sing’s lightweight high strength high-end veneer door core.

The biggest and best door companies, millworks, and custom door manufacturers love it, and you will find them using Sing Core inside all their high-end custom large veneer doors. And that’s why you’ll find them at the top of the tallest building in the United States of America, World Trade Center 1‘s Freedom Tower.

Telegraphing and Crossbanding

The most environmentally conscious way to create a veneer door is with a thin veneer material, such as 0.020-inch veneer. The only problem with this thin veneer is telegraphing.

It is normal to crossband veneer, which basically doubles the price of the veneer, to prevent telegraphing.

Not necessary with Sing’s super-smooth veneer door blanks. He uses his patented veneer door technology to create an extremely smooth surface to lay veneer on flawlessly by using a thin later of MDF to accommodate the lamination of a thin veneer.

Problem solved.

|

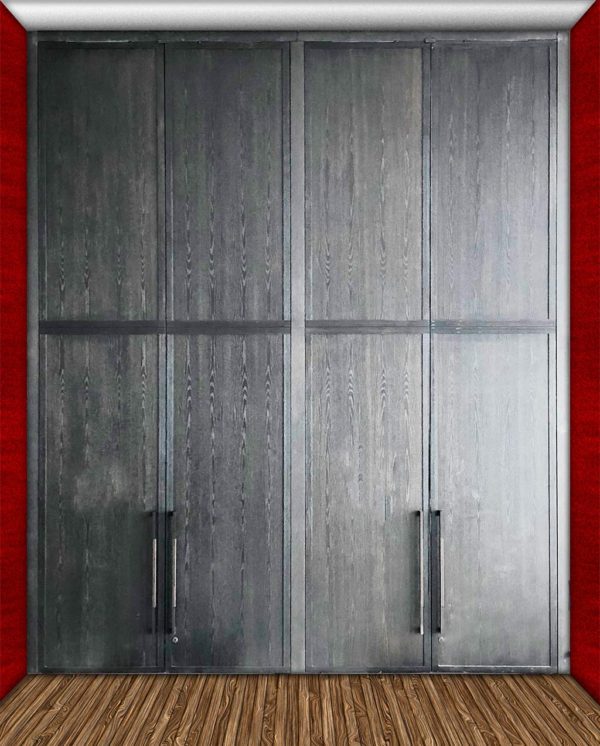

Large Oversized Veneer Doors

When architects spec an architectural veneer door, if it is a very large door (anything over 8 ft tall or 4 ft wide) they are far better off going with a thin wood stave surface. Wood stave consists of wood planks cut into thicknesses of 1/8 to 1/4 -inch thickness. Then this solid wood is applied to Sing’s door blanks.

Veneer is normally limited in available lengths, whereas planks of specific wood species are generally available in longer lengths. This can accommodate the long length necessary for a vertical grain veneer door design.

Plus, if it’s done right, your high-precision large wood stave door with Sing’s core inside looks just like a solid wood door. Only it weighs far less than any other solid core door, and can be guaranteed not to warp, bend, twist, cup, or otherwise fail for 50 years.

And no other door can come backed with such an impressive guarantee.

Even though Sing’s doors are desired by nearly everyone, to have such a door may be cost-prohibitive for most. It is more common to find high-end veneer doors with Sing Core inside in the most expensive homes in the USA. You may find them used in scientific research, and anywhere in the world, from beneath the sea (US Navy) to outer space (NASA) and anywhere in between.

Once you’ve experienced a high-end veneer door of such magnitude, you will agree with the professionals who insist on using Sing’s patented solutions, that,

“It’s the only way to do it.”

Sing Core is the only way to build a big veneer door that can be guaranteed for 50 years. The only way.