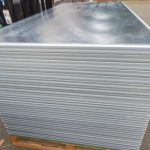

Sing Insulated Aluminum Panels are an Eco-friendly unique combination of traditional high-end carpentry skills and modern space-age technology alternative to other insulated aluminum panels that are lightweight and high strength and proudly made in the USA.

What makes Sing Insulated Aluminum Panels different from other insulated aluminum panels?

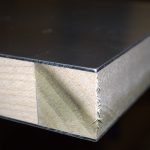

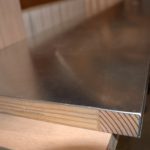

The beginning of the Sing Insulated Aluminum Panel’s uniqueness, you must start at the heart of the insulated aluminum panel, which is the SingCore. The patented core features a structure grid built of vertical grain torsion box. For many years, torsion box has been known to add strength and stability to large structures covering long spans while reducing the overall weight.

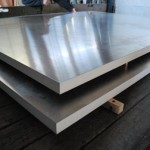

Left to itself, the torsion box structure is traditionally left empty. Instead of being left empty the empty spaces inside the torsion box structure grids are filled with rigid foam insulation, which gives the Sing Insulated Aluminum panels their insulation R value and unparalleled shear strength. The substructure is then sandwiched between two aluminum stress skins and laminated with formaldehyde-free glue, to form an insulated aluminum panel which is stronger than steel (660 PSI) pound for pound.

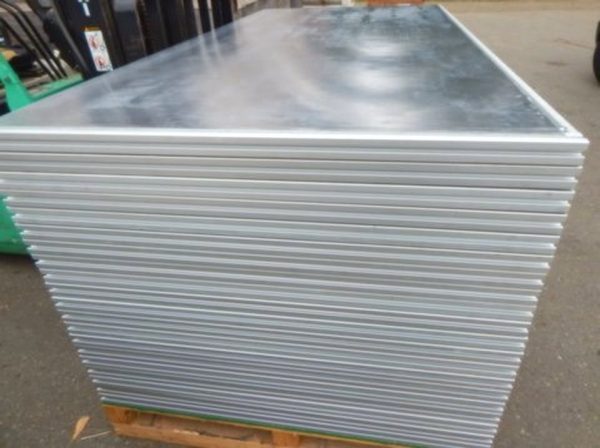

High Precision Insulated Aluminum Panels

No other insulated aluminum panel is so high precision while other core materials vary in thickness across the span of the panel SingCore exemplifies new standards of precision with extremely accurate tolerance of +/- .006 inch.

This extreme high precision is why Sing Insulated Aluminum Panels are used in high-end industrial applications throughout the United States government and science industries including the military, aerospace and NASA.

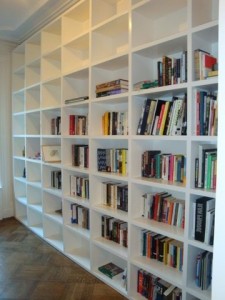

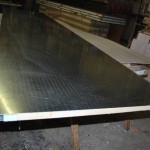

Aluminum Raised Floor, Shelving

You can use Sing aluminum panels as shelves or raised flooring throughout your private or commercial vehicles for better handling cargo. The lightweight and high strength offers organization and clarity, without compromising vehicle weight or handling, so you can add any configuration or levels which would best suit your needs.

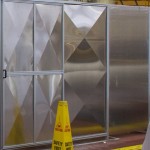

Photos (above) show Sing aluminum panels installed in a van being used as a raised floor, shelf, or truck bed.

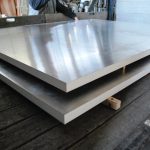

Custom Insulated Aluminum Panels

Insulation R value starts at R3.5 per inch and can be increased to meet your architectural specification by filling the torsion box voids with other varieties of rigid insulation materials possessing higher insulation values and/or fully encapsulated insulation and substrate.

In fact, all Sing Insulated Aluminum Panels are custom manufactured in our factory located in the scenic Pacific Northwest to architectural specifications. It’s as if each insulated aluminum panel is an individual work of art. Specifications may include any variety of materials to meet specific high performance standards.

Other Applications

Not restricted for only use as industrial insulation panels, Sing Insulated Aluminum Panels are found in commercial applications, such as retail, office, refrigeration and hospitality industries and in high end real estate and homes as insulated aluminum doors.

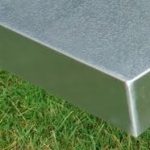

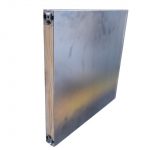

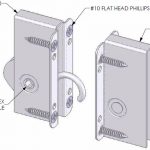

Insulated Aluminum Doors

Sing Insulated Aluminum Panels are probably the best material to use for creating insulated aluminum doors, especially if the door in question is a large, oversized door. The lightweight, impressive shear strength and insulation reinforcement makes large doors foolproof with accuracy higher than solid steel at a fraction of the weight, reducing the cost of any large high-end metal door project immensely.

Cut Down on Expenses

The weight of the metal door dictates hardware and supporting structure requirements, which are expensive considerations for heavy doors. Heavy doors are also more expensive to transport and install requiring heavy equipment and labor, while insulated aluminum doors made with Sing Insulated Aluminum Panels are lightweight, less expensive to ship, handle and install. Plus the structural insulated panels cost savings of having an insulated end product as well as doors that require less maintenance over time.

50 Year No Fail Guarantee

Only Sing Insulated Aluminum Panels can be guaranteed not to warp, bend, twist or otherwise fail (including full structure guarantee) for 50 years. That’s an impressive 50 year guarantee that is not something seen in industrial, commercial or residential industries. This 50 year guarantee would not be possible if not for the unprecedented structure strength of SingCore inside each Sing Insulated Aluminum Panel.

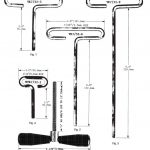

- Aluminum metal doors strength test