Sing Substrates are far superior to other substrates used in a variety of applications, solving many issues in design, architecture, construction and industry.

Advantages of Sing Substrate:

- Lightweight

- Super-strong (stronger than steel)

- Torsion-box technology

- Insulated

- Eco-friendly

Sing substrate is changing the way that things are made. Here are some of the options that you have for using Sing Substrate in your next project:

Sing Sandwich Substrate

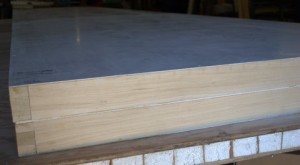

Our most convenient substrate format is the Sing Sandwich panel. This substrate could be custom manufactured to meet your specifications and requirements for strength and flatness. Our standard Sing Sandwich substrate is Sing Core “sandwiched” between 2 luan wood skins.

Our most convenient substrate format is the Sing Sandwich panel. This substrate could be custom manufactured to meet your specifications and requirements for strength and flatness. Our standard Sing Sandwich substrate is Sing Core “sandwiched” between 2 luan wood skins.

Sing Sandwich sheets

Sing Sandwich sheets are extremely lightweight and pre-cut in sizes that make it easy to package and ship to your location. This is the best and most convenient format for adding patented Sing Core technology to your product line.

What makes Sing Sandwich Substrate so popular?

It is so user-friendly and has such a wide variety of applications. And it is so easy to use; almost anyone can make their own lightweight, super-strong materials using our Sing Sandwich Substrate.

How Easy Is It?

This is how simple it is to for you to use our substrate. All you have to do is to coat the underside of your bottom skin with regular carpenter glue, place your wood edges atop the glued-side of the skin, then fill the void with Sing Sandwich substrate pieces until full. Coat underside of top skin with regular carpenter glue, place it on top of your completed work and cold-press until dry.

Click here for step-by-step-instructions (with photos) on How to Build a Sing Panel

Sing Panel Substrate

Our most popular substrate format is the Sing Panel. Our standard sing Panel substrate is a Sing Panel that is 2-inches thick, with wood edges and luan wood skins. This substrate could be custom manufactured to meet your specifications and requirements for strength and flatness.

Our most popular substrate format is the Sing Panel. Our standard sing Panel substrate is a Sing Panel that is 2-inches thick, with wood edges and luan wood skins. This substrate could be custom manufactured to meet your specifications and requirements for strength and flatness.

Sing Panel Substrate is so easy to use as substrate, that our most popular format when used as substrate is the Sing 2×12.

Sing 2×12

Sing 2×12s are pre-manufactured in the most convenient size for wood workers and mills. A shop can easily rip or cut Sing 2x12s into any size needed on demand, and the inventory is easy to management in this convenient size.

Sing 2×12s are pre-manufactured in the most convenient size for wood workers and mills. A shop can easily rip or cut Sing 2x12s into any size needed on demand, and the inventory is easy to management in this convenient size.

Multiple Sing 2×12 substrates can be bonded together resulting in a substrate panel that can be any size.

Of course, your Sing Panel Substrate can be made to any size to meet your needs.

Sing Substrate Options

Depending on your needs and application, a variety of Sing Substrate options are available for you to take advantage of this revolutionary new technology. For example, Sing Substrate is available in:

- Plywood

- Aluminum

- Solid wood

- Concrete

- Stainless Steel

- … and many more …

Some of these options may need special adhesives for bonding to other surfaces when used as substrate. Our standard surfaces only require standard wood glue to be bonded with other wood-compatible skins or materials. To ensure your satisfaction we encourage you to check with our staff prior to using non-standard surfaces to bond to.

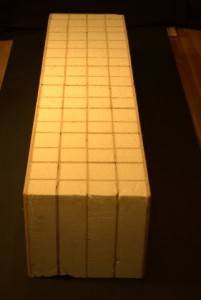

Sing Core Block

Raw Sing Core is available for your substrate need in convenient-to-use blocks. Some special handling and processes are required to maintain structural integrity. If you are interested in utilizing and warehousing your own Sing Core on-site, Click here for more information on Sing Core Blocks.

Raw Sing Core is available for your substrate need in convenient-to-use blocks. Some special handling and processes are required to maintain structural integrity. If you are interested in utilizing and warehousing your own Sing Core on-site, Click here for more information on Sing Core Blocks.

Save Money

If you are so equipped, why not do it yourself. You might be able to save money by manufacturing your end products yourself. Certainly you would experience huge reduction in shipping costs.

We Can Do It for You

Even though many of our clients have the ability to manufacture their own end-product using Sing Core Substrate, some of them just want everything pre-manufactured to their specifications; that’s where we excel.

We can make your customized end-product for you in our specially-designed and outfitted factory.