Sing Core has been providing the only true flat large doors that can be guaranteed to stay flat for 50 years regardless of size.

Sing Core has been providing the only true flat large doors that can be guaranteed to stay flat for 50 years regardless of size.

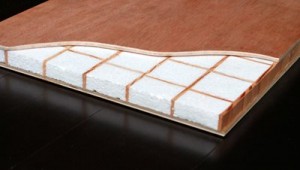

Thanks to Sing’s patented torsion box/foam composite technology along with years of expertise of building large oversize doors that meet or exceed even the most demanding architectural door specifications and solving the challenges that face designers and builders expanding the scope of possibilities that would have otherwise been unattainable.

This new scientific process takes many factors into consideration when formulating the superior composite technology to build the biggest high-precision (within .0006 in. tolerance) guaranteed true flat doors warranted not to fail even under the most rigorous conditions.

Large doors present the designers and builders with a variety of challenges, including:

Large Door Weight and Strength

In most cases to achieve a certain level of flatness and strength to avoid movement (warping), heavy materials, like steel, are used to maintain an acceptable degree of flatness. Even so, when using this method one sacrifices precision due to the welding process.

Compared to other materials Sing Core is the lightest weight core material that can also provide an unfaltering true flat substrate for the door. This lighter weight reduces the demands on the hardware and structure to support formerly heavy doors, while also reducing transportation and construction costs (no heavy equipment highly-skilled laborer necessary for installation/transport).

The genius of the torsion box/foam composite core is in its unparalleled strength (660 PSI in comparison to other honeycomb core material that boasts 10 to 110 PSI).

The shear strength is multiplied by the wood torsion box structure grids that can be reduced in size to achieve even greater performance results if necessary.

Warp, Bend, Twist or Cupping of Large Doors

Large doors – especially those featuring natural materials, like wood, LVL or other traditional composite materials – tend to warp/fail due to exposure to the elements or temperature change in one or both sides of the door because it is inherit in the nature of wood to adapt to its surroundings by contracting or expanding.

Large doors – especially those featuring natural materials, like wood, LVL or other traditional composite materials – tend to warp/fail due to exposure to the elements or temperature change in one or both sides of the door because it is inherit in the nature of wood to adapt to its surroundings by contracting or expanding.

Sing Core’s patented torsion box grids are adhered to the surface materials with the highest gripping formaldehyde-free adhesive that would delaminate from the insulated structural foam material if not for the nature of the natural wood structure grids that constantly corrects for any potential movement across the surface of the large door.

It is this science that keeps the warp-free doors flat in conjunction with composite materials that can be modified to meet the expectations of door over the expected life of the project (up to 50 years, guaranteed).

Large Door On-site Assembly

Though Sing Core can build door blanks as big as 50 ft. transportation could be a problem (unless used in military applications) there are many ways of joining Sing panels on site.

Though Sing Core can build door blanks as big as 50 ft. transportation could be a problem (unless used in military applications) there are many ways of joining Sing panels on site.

The most common ways that door manufacturers deliver large doors is on separate pieces that are assembled (or stitched together) on the job site prior to installation. This is an acceptable way to transport large doors (that may have been too large to ship by traditional methods) but when assembled, the door at the site is likely to be far from perfectly flat and the seams are likely to fail, if not immediately following assembly, then in the near future.

Only Sing Core has an on-site assembly process (similar to biscuit assembly) that can provide nearly seamless results without failure. These results would not be achievable without patented Sing Core components.

Free Large Door Consultation

In order to assure that you achieve the results that you desire to achieve, we offer free large door consultation for our commercial large door designers and builders to determine the substructure and facing composite and/or assembly components necessary to guarantee your oversized door not to fail for 50 years.

-

- Length

- Width

- Thickness

- Surface material

Our large door specialists will need to know the overall size of the opening, the size of the door (the length, width and thickness) and the surface material desired.

Our large door specialists will need to know the overall size of the opening, the size of the door (the length, width and thickness) and the surface material desired.

Using our composite door technology, your large door could feature any flat surface material and still remain true flat over the life of the door.

-

- Regular use

- Exposure

- Strength/resistance req’d

- Sealing/mounting method

- Insulation req’d

Other information to create the perfect door blank for your application may include the regular use of the door, exposure to the elements, strength/resistance required, sealing and insulation qualities – all important information that alters the composition of your big door.

Large Door Turnaround Time and Quantity

The final piece of the picture is the how many you want and when do you need it by.

The final piece of the picture is the how many you want and when do you need it by.

Since your Sing large door solutions are custom manufactured to your specifications and proudly Made in the USA, we can accommodate even the most rapid delivery constraints for your rush orders.

Our normal turnaround is 4 to 6 weeks, but we can deliver large door orders (for example one recent job was 700 doors in 10 days) to make sure that you get the door you want when you want it.

Click here for pricing and ordering details.