Lightweight, yet 660 PSI Strong

Our Structural Core allows our panels to weigh 50% to 87% less than wood depending on the skin type, grade, and thickness.

Standard grade panels have been independently tested by the University of Washington at over 660 PSI. Sing Panels can be engineered to achieve over 1,000 PSI.

Insulated and Sound Deadening

The Structural Core was engineered to provide insulation value with R-values that range between 3.5 and 6.5.

For sound, customize your door to reach high STC ratings. Select from either polystyrene or urethane foam for your core depending on the needs of your project.

Warp-Free and Easy to Woodwork

Because the strength of our core doesn’t rely on wood (a naturally warping material), Sing Panels’ patented vertical grain torsion box core Structural Core allows us to provide the only 50 year warp-free guarantee.

We can install custom wood blocking as per your project’s needs for hardware installations.

Customizable to your project’s needs

We hand mill each one of our orders here in the USA (Washington State) to exceed the requirements of your project.

Dimensions

- Length x Height are customizable to your project’s needs. We’ll also custom manufacture your panel’s thickness, grade, core grid size, skin type and thickness, edging, trimming, and internal blocking as per provided drawings.

Skin Options

- For trade professionals, visit the Estimate Page and select the “Skin Type and Thickness” dropdown to view our skin offering.

- Some of our skins include Birch, MDF, Mahogany, Fir, Cedar, and metals such as Galvanized Steel.

Panel Thickness

- Thickness is customized to your needs. Min thickness is 3/4″. There’s no maximum thickness. We’ve manufactured door substrates at 4″+ thick.

Sing Panel Grades

Standard Grade

Standard grade panels utilize our patented torsion box core and provide unparalleled strength and lightweight properties unachievable with traditional building materials.

Professional Grade

Professional grade panels can be guaranteed warp-free for 50 years. Composite stiffener technology is integrated with the structural core, which prevents warpage and provides a truly flat panel.

Hot Press Ready Grade

Hot Press Ready grade panels are our Professional grade panels with an extra aluminum sheet under your skin selection that your shop can hot-press.

Sing Panel Specifications

Size

We can custom press SingCore panels to any size required. For some projects where multiple panels must be joined, we custom fabricate a SingCore torsion box spline. Additional labor and shipping costs apply to orders of oversized panels.

Thickness

We can design Sing panels in any thickness you may need. In previous projects, we have manufactured panels anywhere between ½” (must be HPL) to 8” thick. Our standard minimum wood skin thickness is 3/4″.

Skin Type and Skin Thickness

We can use any flat building material as a skin without compromising our panels’ structural integrity. Our most popular skin type is ¼” birch, but we’ve worked with a variety of materials including cold rolled steel, glass, and even cement board and concrete. Click here to view skin options.

.

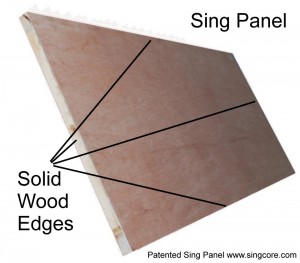

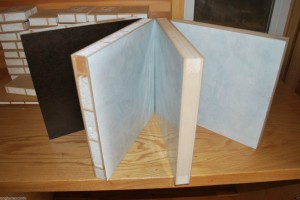

Edging

Sing panels are available with either open or closed edges. Clients sometimes choose open edges (see: Sing sandwich) when they intend to work the panel post-manufacturing. With closed edges, the skin material is pressed and glued over a solid wood frame, ensuring a complete seal between skin and edging on all sides. Edging is 1.25” solid birch, but we offer multiple edging options including african mahogany, red cedar, port orford cedar, sapele cedar, white oak, and even T-slot aluminum.

Trimming

Unless otherwise specified, all of our panels are shipped untrimmed, meaning the edges aren’t detailed and there may be bits of glue or wood for the buyer to work. If you need a clean finished panel on arrival, simply specify in your order. Open edged panels will always include trimmed edges.

Internal Blocking

Many custom projects require specific hardware to be installed in our panels post-production. To allow for this, we offer additional wood blocking anywhere within the panel, according to your provided drawings and specifications. Increased amounts of internal wood blocking will increase the weight and decrease the warp-resistance of your panel since wood is a product with warping tendencies.

Embedded Chases

Custom Sing Panels can be manufactured to your architectural specifications which may include special chases for plumbers to route hot and cold water feeds via plumbing or electricians to run electrical wiring, communications and security through a patented Sing panel. Every Sing panel is custom manufactured in our factory, and we can have your wire chase or plumbing pre-installed within your panels at any location specified.