Are you in a position to perform some of the manufacturing of your Sing Composites and/or building products at your facility just like we do?

By special invitation, we’re making available to you the material that is

By special invitation, we’re making available to you the material that is

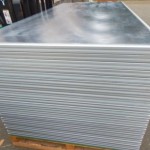

- Used as substrate to build Sing Composites

- The most diverse material ever invented

- Super strength and lightweight at lower cost

The most shocking part is that Sing Core is a truly green product using the strongest renewable fiber provided in nature, requiring much less energy to produce. Sing Core is stronger than most of the foam and sandwich core used in the aircraft industry, Sing Core might be the only substrate in construction industry acquiring the highest strength and most lightweight core ever invented.

There is almost nothing Sing Core can’t do. Please visit our product and production site to see some of the products that we have made and you could make any of these products using Sing Sandwich material without making any mistakes.

Enterprising woodworkers, millworks and factories are taking the challenge and incorporating Sing Composites into their product lines. The ingenious engineers have developed a method to bring Sing Core technology to your facility, no matter how large or how small, saving you money.

To take advantage of this special offer, call 360-495-3577

You have been selected to join with us in this private, by-invitation-only limited offer.

- We will provide you with our patented Sing Sandwich material… deeply discounted

- We will guarantee your discounted price for one year

- Free Shipping for the first year

- Take advantage of our bulk materials pricing

This offer is exclusive to you, and we have worked with woodworkers who have helped us maximize this offer for your greatest possibility of success.

Create Your Own Sing Composites

Create Your Own Sing Composites

You can have access to Sing Sandwich material to make your own Sing Composite, or let us take the more challenging jobs that our factory is specially designed to accommodate, like, oversized doors and super large single-piece panels, or posts and beams up to 50 ft in length in wood, aluminum, metal or cement materials.

Sing Sandwich

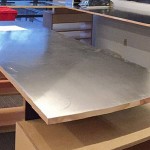

Sing Sandwich material has a wide range of uses and is the prominent core material in many applications. The Sing Sandwich material is what makes the process of building your own Sing

Sing Sandwich material has a wide range of uses and is the prominent core material in many applications. The Sing Sandwich material is what makes the process of building your own Sing

All you have to do is to order Sing Sandwich material to your specifications.

To accommodate special needs and precision sanding, the core material can be sliced to any thickness. Skin thicknesses can be your choice of wood thickness including 1/8”, 1/4” or 3/8” to provide you with enough surface material.

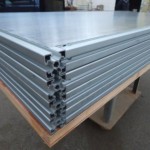

Special-sized Sing Sandwiches

When your shop or factory is using Sing Sandwich material to build your own Sing Composites on site, we make it available in sizes that accommodate this new crowd manufacturing concept. We are shipping this special material in panels as small as 24” x 48”, making the material easier to package and less expensive to ship to your location. Then you can build your own material on-site using our drop-in method of Sing Composite manufacture.

Wholesale Sing Sandwich Pricing

Wholesale Sing Sandwich Pricing

It is our desire to see your shop or factory produce truly high-end made in America product using Sing Sandwich material, so we have specially-priced this material for those whom we have invited to participate in this nationwide crowd manufacturing project.

Easy to Manufacture

On your end, the Sing Sandwich material is so easy to work with. Basically, you just treat it as you would any other solid wood product but without of the problems – such as movement due to moisture change, warp and cupping – causing your end product not to remain true flat.

You can build your own panels or building material by assembling the composite components together and bonding with regular carpenter glue, like you do now, thanks to the wood bonding areas of the Sing Sandwich.

How Easy Is It?

1 Easy to glue with white glue (unlike raw Sing Core* which requires special glue).

1 Easy to glue with white glue (unlike raw Sing Core* which requires special glue).

2 Works just like any other substrate such as Balsa wood, particle board or plywood core but is much more dimensionally stable, lightweight, is stronger and does not attract moisture.

3 Save money in crate and shipping costs by purchasing our standard sandwich 24 inch x 48 inch. We are offering free crating and shipping during promotion period of time.

4 Easy to cut to smaller size and sanding to desire thickness by using table and belt sander; then drop in the frame with skin. Next, press to your build your door panel, table top, stair treads, wall panel, floors, etc… You can even bond with other material skins, like, aluminum, FRP or cement to create an endless line of end products and/or building materials.

To take advantage of this special offer, call 360-495-3577

We are partnering with you, and will share our technology with you for your success, because your success is our success.

We will guarantee your discounted price for one year

No surprises here… This is not a tricky one-time offer… Working with our woodworkers, they have expressed their desire to have access to this reduced price over a longer period of time enabling them more time to experiment, conduct testing and play with different applications.

No surprises here… This is not a tricky one-time offer… Working with our woodworkers, they have expressed their desire to have access to this reduced price over a longer period of time enabling them more time to experiment, conduct testing and play with different applications.

You asked for it… Here’s you go, we provide you with our fixed-discount-price guaranteed for only those who take advantage of this special offer for a full year.

Free Shipping for the first year

One of the advantages of using sing Core for any application world-wide is the low cost to transfer an end product inexpensively due to its being so lightweight… especially when compared to items manufactured out of traditional materials that are much heavier; even no-strength Balsawood is 1.5 to 2 times heavier (depending of grade) than Sing Core; particle board is 10-times heavier.

It is very easy to ship Sing Core Blocks due to their structural integrity; even so, we guarantee free replacement of any Sing Core Block that might be damaged in shipment. So, for you, in this one-year offer, we will even pay the freight to ship Sing Core to your continental USA address.

Take advantage of our bulk materials pricing

You already get the lowest price on raw Sing Core materials; what about the other items you might need? For instance, we provide you with special discount pricing on the two types of glue that we use in our factory; our special white glue formulation.

You will also be able to share our wholesale pricing on in-stock materials, like, hardwood skins, styles and rails, and other materials that we have in stock (that varies from time to time) that we buy by the railcar. We pass these savings on to you.

* For those of you that would like to use raw Sing Core material in your facility, there is a program available for you, also… Feel free to inquire.