50 Year True Flat Replacement Doors

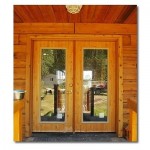

Building the most stable door is our specialty. With our patented true flat technology, Sing Core provides clients with insulated Eco-friendly lightweight high-strength doors that prevent wood warping doors. Often we are sought out for replacement doors to solve the problem of doors that fail following installation. Doors – especially exterior, large or special purpose doors – are prone to warping, bending, twisting or cupping.

Why Do Doors Warp?

So many things can contribute the failure or the success of your large door’s performance.

- Size: Length, width, thickness

- Skin: Some materials are more prone to warp than others

- Core: The core material will affect the door’s overall performance

- Environment: Exterior facing direction, weather, exposure to moisture and/or other conditions.

FREE CONSULTATION for your next large door project. You tell our non-warp experts your door’s specifications and expectations and they can provide you with the only non-warp solution guaranteed for 50 years.

What if you started with a Sing door instead of using it as a door replacement?

Only true flat wood front doors by Sing Core can be guaranteed to be flat and stay flat and stay solid for 50 years. Most foam-filled doors might be straight but need patented Sing Core structural grids to keep it strong and tough to avoid failure following impact or due to exposure. Creating a warp-free large door is a challenge for all door manufacturers because it is almost impossible to make a large door that will be straight and stay straight over time. That is, of course, until the invention of Sing Core.

How can you make the most stable door that can be guaranteed true flat for 50 years?

Sing Core has developed true flat technology that consists of three phases.

#1: Sing Core

#1: Sing Core

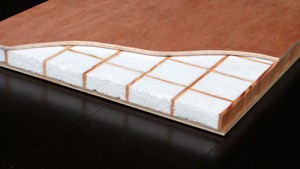

The first phase is to start with patented Sing Core as the basis of your true flat door. Sing Core is a composite honeycomb material consisting of natural vertical wood grain torsion box where the voids are filled wall-to-wall with solid recycled foam material that is 90% air. The natural wood torsion box inner frame yields only 8% of this natural resource in comparison to a solid wood door. This provides the strongest Eco-friendly, lightweight door core that will not warp, bend or twist.

#2: Skin Selection

The skin selection is matched to your desired appearance of the door. Do you desire a solid wood grain door? If so, what wood species? Besides wood, we can manufacture a Sing door to host any flat building material, including (but not limited to) aluminum, ceramic, concrete, glass, fiberglass (FRP), plastic, LVL, MDF, Mag-board, stainless steel, veneer, even more custom high-end surfaces like, Kevlar, etc…

The skin selection is matched to your desired appearance of the door. Do you desire a solid wood grain door? If so, what wood species? Besides wood, we can manufacture a Sing door to host any flat building material, including (but not limited to) aluminum, ceramic, concrete, glass, fiberglass (FRP), plastic, LVL, MDF, Mag-board, stainless steel, veneer, even more custom high-end surfaces like, Kevlar, etc…

#3: Performance Enhancement

#3: Performance Enhancement

Next, our true flat experts review the expected performance and usage of your door. Based on how you want your door to perform and under what conditions, our experts may incorporate additional stress skins to bond directly to the Sing Core base to match your desired outcome. How large are the dimensions of your door? Will your door be exposed to the elements? What extreme exposure, if any, will the door face? Will your door be used: Underwater, in temperature-controlled environments, as sound proofing, to prevent harm to persons or property, etc…?

Any Sing composite door can be guaranteed true flat for 50 years, while matching the appearance of:

Framed Stile and Rail Doors

Also called raised panel doors (when in reality it is not raised panel at all. The appearance of “raised panel” is obtained by graduated cutaways that compromises the integrity of the door). These doors are normally made of several different solid wood (or composite) pieces assembled by dowels or other connections.

The individual components, connectors and adjoining seams tend to move due to moisture, temperature change or with heavy use or vibration over time.

By examining the red door (left) you would never know that this wood Sing door was not stile and rail yet will last for centuries without fail even though exposed to the weather 100%. The appearance of this door perfectly replicates the appearance of the stile and rail doors that were replaced.

Flush Doors and/or Solid Wood Doors

Solid wood doors are a romantic and nostalgic nod to days gone by, but solid wood is well known for bending, warping and twisting due to the natural grain of the wood itself.

Solid wood doors are a romantic and nostalgic nod to days gone by, but solid wood is well known for bending, warping and twisting due to the natural grain of the wood itself.

LVL is a heavy solid core that is more consistent than solid wood in terms of warp, bend and twist when used in wood doors but will often fail (especially in doors over 10 ft. tall) and once it does begin to move, cannot be stopped or straightened as it has no memory.

Foam Core Doors

Foam core doors such as most FRP door, metal door, etc… are lightweight but have no strength or structural integrity.

Almost any impact will compromise the door causing the door to weaken and/or delaminate, unless it incorporates patented Sing Core structure grid technology.

Break a Leg

Only Sing doors can take the abuse without running the risk of breaking or delaminating.

If you kick a door, it is likely to break; kick a Sing door and you will break your leg.

The Sing Secret

The secret behind Sing Core’s success is not merely in the torsion box design (which has been used for hundreds of years) but in the orientation of the natural wood grain used to form the grids that are the basis of the internal structure for the patented non-warp base material enhanced by stiffening technology to counter-act potential warp.

The secret behind Sing Core’s success is not merely in the torsion box design (which has been used for hundreds of years) but in the orientation of the natural wood grain used to form the grids that are the basis of the internal structure for the patented non-warp base material enhanced by stiffening technology to counter-act potential warp.

In the past, torsion boxes were built with horizontal grain, that while running parallel will tend to fail by bending in harmony with the outer wood skin material. Sing Core flips this technology on its edge by contrasting the orientation of the wood grain to be perpendicular to the exterior wood grain resulting in many times the strength.

Previously solid Balsawood core has been used as door core with perpendicular oriented grain successfully but runs the risk of compromise or failure due to its natural characteristics that will also move due to moisture exposure, climate or temperature change. But it doesn’t stop there.

Next, inventor Peter Sing bonded recycled foam (which is a lightweight solid material consisting of mostly – 92% – air) wall-to-wall inside each void of the vertical grain torsion box grids for unsurpassed shear strength and solid core material throughout.

This is how patented Sing Core has accomplished nearly inconceivable strength in the lab (660 PSI, tested by University of Washington as stronger-than-steel pound-for-pound), yet still remaining lightweight.

All this combined with the Sing Composite Formula for specialized stress skin integration results in the only true flat doors that are built to last for centuries.

- Add molding to create stile and rail door appearance

- sing honeycomb stronger than steel lightweight

- lightweight high strength exterior honeycomb sandwich door

- Oversize wood grain pivot doorlightweight

- lightweight high strength sing honeycomb door

- sing honeycomb lightweight sandwich wood sliding door honeycomb lightweight sandwich wood

- exterior lightweight honeycomb door

- lightweight high strength panel

- true flat sing honeycomb sandwich

- Flush Door Closet

- Lightweight high strength moveable wooden non warping doors

- interior true flat stronger than steel lightweight

- patented sandwich door

- Ash Exterior Entry Doors

- modern sandwich sing door

- contemporary insulated sing door

- lightweight patented sing sandwich door

- lightweight honeycomb sandwich door

- insulated Sing sandwich door

- Sing honeycomb lightweight door

- True Raised Panel Doors