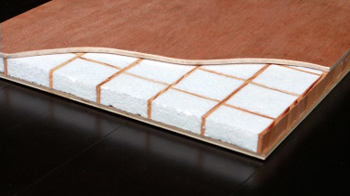

SINGCORE is Torsion BoxSing Core is introducing our new torsion box technology. (click here to see Google image search of torsion box). With our patented Sing torsion box core we can create wood and metal composite panels or post and beams that make solid wood and other solid material such as concrete, aluminum, steel, plastic less desirable. Sing Core Torsion Box panels are dimensionally stable, lightweight, and have a very high strength/weight ratio. Click here to learn more about our torsion box technology. Products made with the Sing Core torsion box technology:

Unique Applications: |

Sing Panel Applications:

Sing PanelsOur panels are sandwiched using the patented Sing Honeycomb core. Our Honeycomb core has been tested by the University of Washington to reach 660 psi compression strength, a sizable improvement over foam door cores, which reach less than 2 psi compression strength. Sing Honeycomb Core is the strongest, most lightweight, and most eco-friendly core ever made.

|

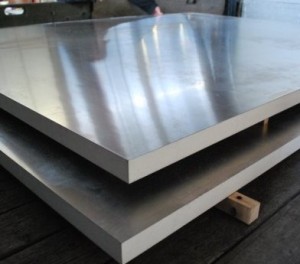

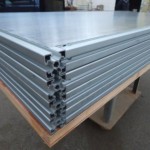

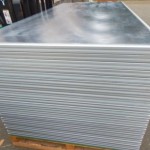

Aluminum Panels

Sing Core Offers the best in aluminum honeycomb panels

Custom Sizes Available

If you have a special custom, architecturally specified, or otherwise unique requirement for your project, don’t hesitate to ask. We are experts in the unexpected, and seek to exceed your every desire. Visit our pricing page for more information and to submit your price quote request.

Use Sing Aluminum Panels (SAP) for a variety of applications, like:

- Standard aluminum panels used for a wide variety of applications.

Cleanroom Panels

- Non-outgassing, non-particulating, chemical resistant panels ideal for controlled environments.

Hurricane Panels*

- Designed to meet high wind loads and resist small flying debris. See also our hurricane door*.

Machinery Components

- for laser staging tables, support structures, fixturing platforms, and in-feed/out-feed tables.

Machinery & Instrument Enclosures

- lightweight cover panels for X-ray processing equipment, machined for attachment.

- Durable, lightweight panels with excellent corrosion resistance for marine applications.

Museum Panels

- Engineered panels ideal for archiving artwork, mounting canvases, and designing gallery exhibits.

PVC Coated Panels

- chemically welded for a seamless, monolithic surface necessary in certain controlled environments.

Signage Panels

- Designed to meet wind load requirements and accommodate reflective coatings used in sign industry.

- Structural panels with safe walking surface on top.

Standard Aluminum Honeycomb Panels

- Our in-stock standard aluminum panels are 4’x 8’, 4’x 10’, and 4’x 12′.

- Custom sizes are available up to 5′ wide and 20′ long or 4′ wide and 30′ long.

- Standard aluminum panel thicknesses are ¼”, ½”, 1’,1 ¾” and 1 7/8″.

- Other thicknesses are available upon request.

- Standard aluminum facing thickness is 0.032 (0.025, 0.040, 0.063 available).

- Facings can be either nonconductive or Electro static dissipative.

Want to learn more about Sing Aluminum Composite Panels? Click Here

Contact Sing Core for all your aluminum panels needs… if you don’t see it, it is likely that we can custom design anything that you need… including massively oversized (our specialty). Email us, today.

*Customer will need to perform lab tests to certify hurricane rating for local code compliance.

- High precision workstations

- Retail office furnishings

- Indoor Pool Hot Tub Cover

SingCore the Secret Empowering Your Imagination

If you can imagine it, Sing Core can help your dreams come to life.

If you can imagine it, Sing Core can help your dreams come to life.

In the world of architecture and design, many creative and artistic people come up with beautiful designs that are difficult to transform into reality due to structural or design details that keep the project from being seen through to fruition.

Sing Core can help you overcome some of these obstacles.

LIFGHTWEIGHT

For instance, if your requires lightweight components to make it manageable, Sing Core is an obvious choice over existing products that may have the strength required, but lack the ability to be lightweight, as weight is commonly the trade off for strength.

SUPERIOR STRENGTH

The structural advantages of some materials, like stainless steel are well known but the cost to your project is in the added weight. In this circumstance stainless steel can have a Sing Core interior, giving you the advantage of increased strength over long spans, while being extremely lightweight.

The lightweight structural integrity of titanium is also understood, though when combined with sing core, the end product is not only more lightweight but is also stronger that titanium alone.

ECO-FRIENDLY

The process of manufacturing and using Sing Core in your projects help promote sustainability and green living for our planet. Sing Core is manufactured with less energy, in less time, with less heavy equipment, waste and fewer man-hours. Sing Core is manufactured out of reclaimed natural resources and recycled material, and is completely recyclable.

LONGEVITY

Sing Core is also designed to last for lifetimes, unlike popular building components that breakdown over s=time resulting in products that need to be fixed, repaired or replaced.

MADE IN THE USA

Sing Core is the superior building material that is 100% manufactured in the USA.

PATENTED TECHNOLOGY

Sing Core is protected by patent, and is also one of the few (if not the only) American Made building material that is exported to other countries to solve their challenges in design and buildings.

Let Sing Core help your creations com to life.

Contact Sing Core today and we will help you get from here to there.

Subscribe

Want to keep up on all the latest Sing Core news?

We are switching our newletter over to a different, more secure system. In order to serve you better and maintain out high integrity while communicating with our fans, supporters, vendors, distributors and friends.

Join the Sing family!

| Get insider access to our unique “true green” solutions. Help make the world a better place by learning while your earning and teaching others. |

Sing Core YouTube Videos 6

Sing Honeycomb Furniture |

Sing Core Strength |

Add Oak to Aluminum Sing Door |

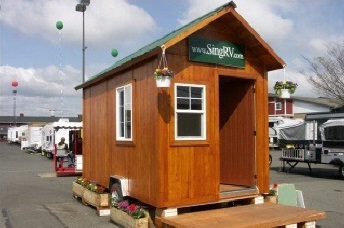

Sing Core Hybrid Tiny House |

Initial Aggregte Work |

Hot Rolled Steel Accordion Doors |

Continue the Video Tour…

Sing Core YouTube Videos 5

GEDC1223 |

Strongest finger in the world or the lightest folding table: New Sing… |

Sing Honeycomb Unbreakable Mirror |

Sing Honeycomb Dresser Assembly Video |

Amazon, Jet Blue and Sing Core |

Build a Portable Modular Floor |

Continue the Video Tour…

Sing Core YouTube Videos 4

Honeycomb vs. Hollow Core Doors (2/13/12 Update) |

Sing Honeycomb Core Door vs. Hollow Core Door |

Testing A Sing Honeycomb Door |

Testing Sing Board(s) [RAW] (Will Update!) |

How to Build a Non-warp Carriage Door |

Large Insulated Room Dividers |

Continue the Video Tour…

Sing Core YouTube Videos 3

Amazon, Jet Blue and Sing Core too |

Sing Core Torsion Box |

Google Project 10^100 Entry for Energy |

How to build lightweight insulated carriage door |

Google Project 10^100 Honeycomb Shelter |

Google Project 10^100 |