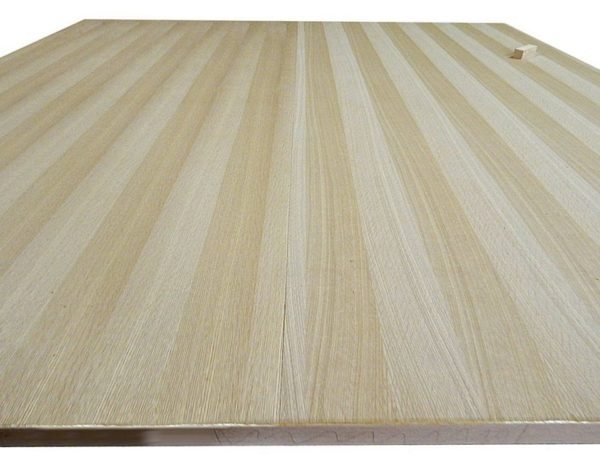

The new generation of solid core door blanks delivering high precision results for the most sustainable doors of any size, even exceptionally large doors, which are lightweight, stronger than steel, and guaranteed to remain warp-free for 50 years.

Inventor Peter Sing supplies the biggest and best door companies with his patented and patent pending warp-free door solid core door blanks which enables them to deliver what are commonly referred to as “the best doors in the world” to their clients who demand the top of the line for their homes and projects.

Sing’s solid core door blanks are unlike any other solid core door blank thanks to Sing’s inventions combined with the expertise of his True Flat Team which works hand in hand with architects, door companies, engineers, millworks, and custom door manufacturers, to achieve stellar results which are impossible to do any other way.

Sing’s clientele is often overheard gladly admitting that,

“There is just no other way to do it.”

To make a large door lightweight, so strong, that is fully insulated for sound deadening and climate control, and be guaranteed not to warp for 50 years, is inconceivable by any other known method besides using Sing’s unique inventions, science, and technology.

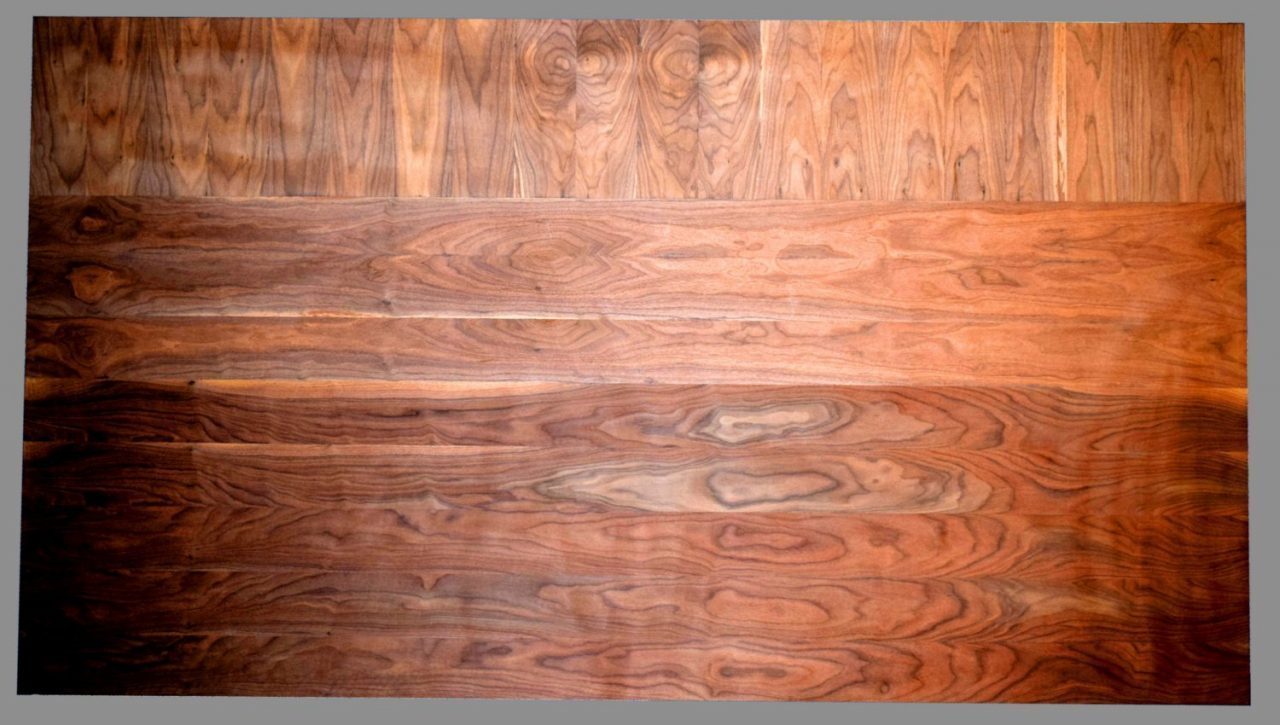

Until now, traditional solid core wood doors were destined to be heavy, especially if large in size, and most likely to fail not long after installation. Wood solid core doors in particular because, well, wood’s natural inclination, being a natural product that moves in response to changes in the environment in which it resides.

That’s why it is standard practice for door companies to exclude large oversized doors from the standard warranty which covers the rest of the door schedule. Large solid core wood doors are generally included on a waiver which exonerates the designers, creators, contractors, installers, and anyone else associated with those big, heavy doors from any responsibility for the door’s performance whatsoever.

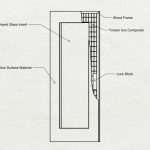

Because until now, there was no way to make commercial grade solid core wood doors that had such high performance. For instance, a solid core wood slab door with Sing Core inside,

Moisture content is the main enemy for any large solid core MDF door slab, so proceed with caution when approaching the integration of any MDF door where moisture may be present. Areas to be avoided include bathrooms, laundry rooms, and kitchens, and MDF is not recommended for use as exterior doors.

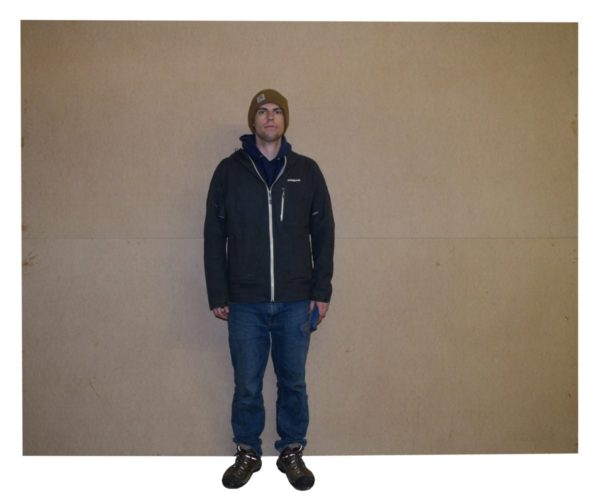

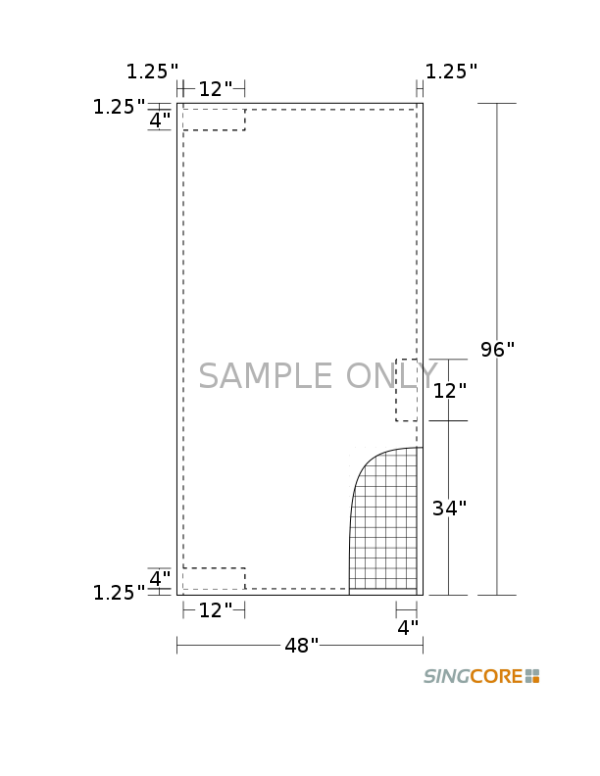

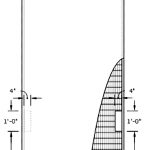

In terms of high precision, Sing’s unfinished solid core door are straight and consisted with .006-inch tolerance and 660 PSI for strength. Its statistical data, like this, which makes Sing’s solid door core break the boundaries set by traditional building methods.

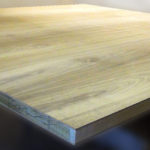

The most popular wood solid core prehung interior doors are found at your local home improvement warehouse, though you will not find solid core door blanks with Sing Core inside at those locations because Sing Core does not actually make doors. But what they do make is the only Eco-friendly lightweight solid core door blanks that will not warp, and Sing’s factory also provides a premiere unfinished solid core veneer composite door slab that outperforms anything else available.

At present, the Sing Core factory does not create any solid core door prehung but they do provide their exclusive warp-free solid core door blanks to the very best high-end door companies, millworks, and large custom door manufacturers in the world.

That might leave you asking,

How can I get a Sing Core door?

Even though you can not just run down to your home improvement warehouse and pick one up, its not as difficult as you might think. If you are working with an architect, he can simply spec a door “with Sing Core inside,” then Sing works in concert with the entire team to bring your dream door(s) to life.

If you are working with a local millwork, they will order up the solid core exterior wood door blanks that they need to get the job done and take it from there.

Your local door company is the best way to get a Sing solid core door prehung, because in most cases that is what they do. Unless they are a highly custom door manufacturer, most door companies get their doors made off-site (most of those doors are not made in the USA), then they (if necessary) finish and prehang them on site.

In this case, the door company will order up whatever Sing solid core door slab they need, finish, and hang the door, then you can pick it up, or you can arrange for door installation at your desired location.

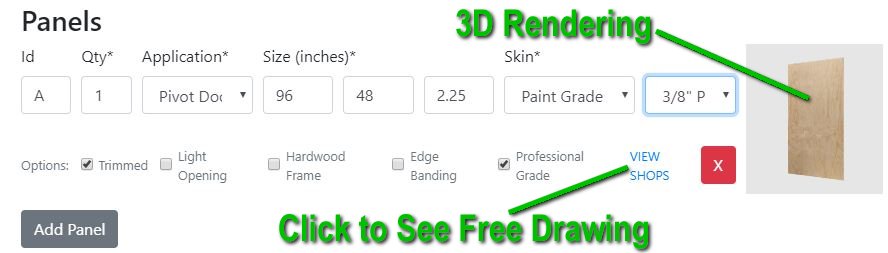

The best way to get to the next level in the world’s best solid core door blanks by Sing Core, Submit a Price Quote Request. You will be assigned to a salesperson who can help you work out all the details of helping bring your dream door come to life.

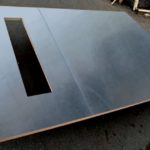

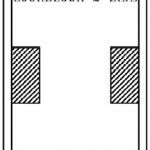

- Industrial Sliding Door