Many people struggle with how to fix a warped door. Nothing is more frustrating than spending your hard-earned money on a nice door, only to have it warp, bend, twist or cup not long after installation.

This problem is magnified exponentially especially if the door is a large oversized door. Some of these high-end large doors can cost tens of thousands of dollars only to discover failure due to warp when the season changes. This can mean job security for door repair services, millworks and contractors serving the account, but can lead to dissatisfaction and frustration for the client.

Patented Sing Core

Dealing with how to fix warped wood doors is considered standard maintenance for high-end applications; that was until the invention of patented Sing Core. Only large oversized wood doors made of Sing Core can be guaranteed true flat – and to stay flat – for 50 years. See: No More warped Doors.

Sing Core solves the issues with warping and eliminates the mystery of the warping door. By integrating Sing Core into your door’s composition you can have an elegant, maintenance-free long-lasting door that will not warp, bend, twist or fail regardless of size or application.

Free Door Consultation

The most prestigious clientele around the world seek out expensive door professionals (Certified Door Consultants) to help design doors that meet or exceed the performance standards. We provide free large door consultation to trade professionals to assure that the door that your client receives delivers the high precision performance that they expect.

Click here to see how patented Sing Core door planks/panels/blanks are made providing the only 50 year non-warping guarantee.

Click here to see how patented Sing Core door planks/panels/blanks are made providing the only 50 year non-warping guarantee.

Demystifying Door Warping

There is no longer any need to be frightened of doors warping, due to our extensive experience in providing doors (even huge, enormous doors) that are guaranteed not to warp for 50 years to the most proficient building designers, contractors, mill works and high end door manufacturers.

The biggest problem for doors is warping (especially in large doors) used n high-end home building projects and commercial projects when building sliding doors, pivot doors and big interior doors.

Most door manufacturers and millworks avoid building doors over 8 feet tall or offer a very limited one year warranty with many exclusions/restrictions to prevent exposure to damages due to warping. Click here to see

When you buy your door, and even following installation, it may or may not be flat. Most doors begin to shift and move following manufacture. By the time your door arrives at the job site, it may already be warped or beginning to experience separation between the exterior surfaces and the core material.

Certainly after years of regular use (paper core, foam core) will warp and/or delaminate.

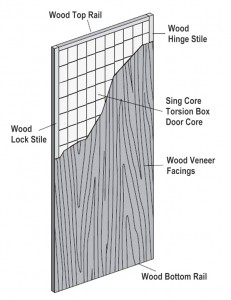

No matter what kind of standard core a door is made from, whether paper core, foam core, SLC (Stave lumber core), particleboard, SCLS (Structure composite lumber), LVL (Laminated veneer), mineral core, MDF, cardboard, etc… warping is inevitable. Even a solid wood door will warp. A sliding or pivot door will have unbearable warp at only ¼ inch due to the reference next to a straight wall or door jam. This warping is even worse in a door over 8 feet because of the strength of the movement. So far, the best solutions have been to only make 7-foot high doors, or to make excuses (i.e., no or very limited warrantees) for doors over 8 feet, or to use gaskets to hide the minor warping, but these are temporary solutions that require costly maintenance and replacement and tarnish the reputations of the building trade professionals involved in the projects. As such, most doors usually do not have warranty protection against the inevitable warping. Even with SCLC (Structure composite lumber core) and LVL (Laminated veneer), commonly used in high end large door will not remain true flat due to the wood fiber constantly moving.

No matter what kind of standard core a door is made from, whether paper core, foam core, SLC (Stave lumber core), particleboard, SCLS (Structure composite lumber), LVL (Laminated veneer), mineral core, MDF, cardboard, etc… warping is inevitable. Even a solid wood door will warp. A sliding or pivot door will have unbearable warp at only ¼ inch due to the reference next to a straight wall or door jam. This warping is even worse in a door over 8 feet because of the strength of the movement. So far, the best solutions have been to only make 7-foot high doors, or to make excuses (i.e., no or very limited warrantees) for doors over 8 feet, or to use gaskets to hide the minor warping, but these are temporary solutions that require costly maintenance and replacement and tarnish the reputations of the building trade professionals involved in the projects. As such, most doors usually do not have warranty protection against the inevitable warping. Even with SCLC (Structure composite lumber core) and LVL (Laminated veneer), commonly used in high end large door will not remain true flat due to the wood fiber constantly moving.

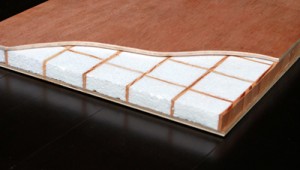

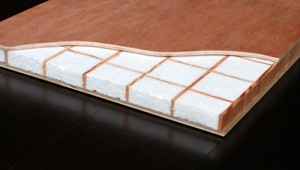

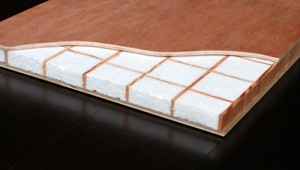

Finally, Sing Core provides a guaranteed solution to the challenges of warped doors and it is the only affordable lightweight high strength solution that can provide 50 years of high performance, remaining straight and true without fail. Plus, Sing Core offers insulation qualities that cannot be found in other strong (heavy) building materials. Only this unique patented torsion box/rigid foam composite can offer the superior strength – bridging long spans, or towering heights – while insulating and providing sound deadening benefits.

Sing Core helps door manufacturers and mill workers build doors which satisfy even the most challenging high-end door market. (Click here to see our client list.) Doors made with our patented Sing core panels are true flat and may be guaranteed to stay true flat for 50 years. In addition, our patented Sing Panels (door blanks) are:

1. Dimensionally stable with a high precision tolerance of +/- .006 inch. This is laser precision which produces the smoothest and most true-flat panels.

2. Fully insulated for temperature control and sound-deadening qualities and which are 3 to 5 times more insulated than solid wood-based door cores.

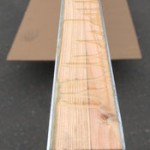

3. Lightweight so that even a 4 inch thick door will weigh only 2 to 3 pounds per square foot. An average wood-core weighs 8 to 10 times more than our patented Sing core.

4. High strength which has been verified by the University of Washington at above 660 PSI, making our Sing panels pound-for-pound stronger than steel. (You could drive a 12,000-pound forklift over them without crushing them!)

5. Water-resistance/waterproof doors made of patented Sing core panels can be completely exposed to the weather without warping. (Click here to see our exterior door gallery.)

6. Eco-friendly and non-toxic structure glue for bonding skins and Sing core.

-

-

Click the picture to see our hardwood plan gallery!

-

wood skin 4

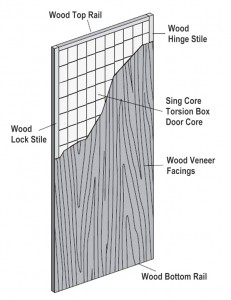

Aluminum skin only for paint grade or wood stave.

-

-

-

-

-

lightweight high strength large honeycomb door

-

-

Add MDF skin or plywood for paint grade and wood grain.

Click here to see how patented Sing core door planks/door panels/door blanks produce true flat stay flat (non-warping) doors in any size, shape or design with a 50-year guarantee. Call us for a free consultation at (360) 495-3577.

-

-

-

-

-

-

-

-

-

-

-

-

Add molding to create stile and rail door appearance

-

-

Oversize wood grain pivot doorlightweight

-

-

-

lightweight high strength sing honeycomb door

-

-

sing honeycomb lightweight sandwich wood sliding door honeycomb lightweight sandwich wood

-

-

exterior lightweight honeycomb door

-

-

-

lightweight high strength sing honeycomb sandwich

-

-

-

True Raised Panel Doors

-