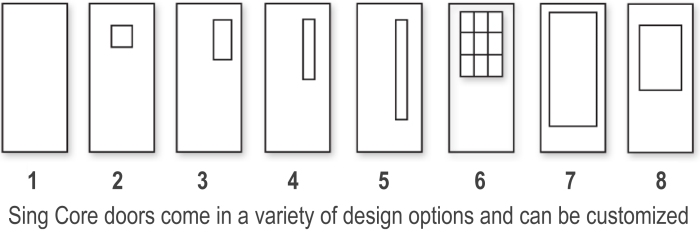

If you would like to know more about how to design a door with Sing Core inside, click here.

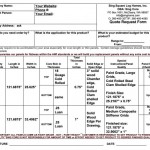

When it comes to building the most unique doors, especially large, oversized doors of any size (up to 20 x 60 ft. or more), type, or style of door, Sing Core’s True Flat Team knows how to bridge the gap between impossible and possible, by applying many variations of their patented and patent-pending technologies to make it happen. Some of our most recent projects include curved doors, Sing stile and rail doors, new patent pending Sing Core stile and rails, long-span wood stave planks, CNC door carving blanks, large sliders with man doors, billionaire home doors, and hot rolled steel doors.

Oftentimes, the most common response is, “We will build it, or have it built, to your specifications, but this door will be placed on a separate rider, excluding it from any other warranty that may be covering the remainder of the door schedule.”

That is, unless they are working directly with Sing Core.

Many of the biggest door companies and high-end millworks are back into the specialty door business because they have partnered with Sing Core.

Why Sing Core?

Sing Core offers solutions that make impossible doors possible, and not only possible, but these magnificent works of art can be guaranteed not to fail, as they are covered by Sing’s

50-Year No Fail Guarantee

These enormous or one-of-a-kind unique doors are nothing short of amazing, with unparalleled service records and longevity, and they are guaranteed not to warp, bend, twist, cup or otherwise fail (including full structure and lamination warranty) for 50-years. No other door in the world comes with such an impressive guarantee unless it has Sing Core inside.

The Most Unique and Challenging Doors

Large doors are not the only unique and challenging doors to come to the attention of the True Flat Team. Many other types of architectural doors will present a huge list of problems that will send door engineers, designers, and custom door makers running for cover, yet they are no problem for the Sing Core factory teaming up with the sophisticated door manufacturer or millwork to accomplish. Like these:

Curved Doors

Curved doors are unique specialty doors, that require precise curvatures, especially if they are being newly installed in a pre-existing wall or structure that is curved. Matching the curvature of the door to the existing wall can be extremely difficult, but the True Flat Team at Sing Core make the perfect curved door to match any curved wall or structure, while still guaranteeing the door for 50 years to perform without warp.

|

|

|

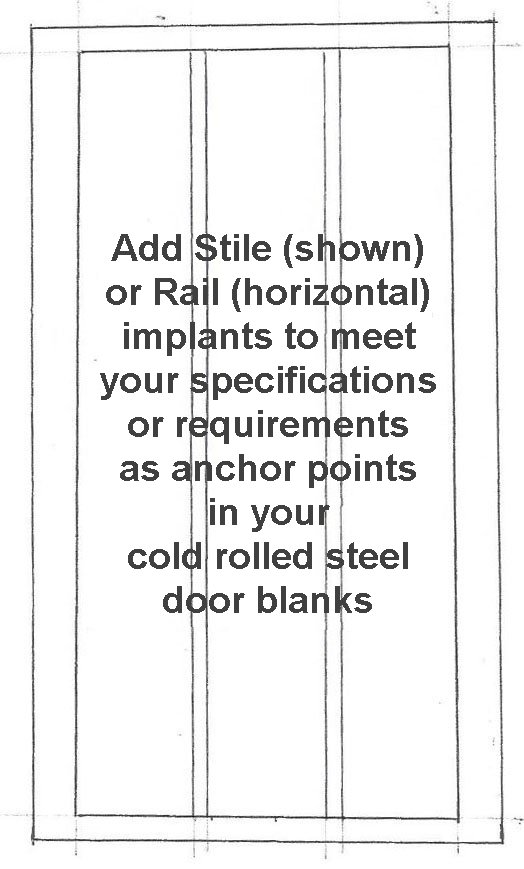

Sing Stile and Rail Doors

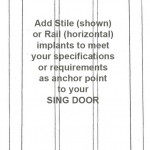

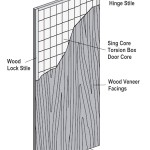

The Sing-style of stile and rail door is a departure from traditional stile and rail door technology. The clients who prefer the Sing-style stile and rail door are looking for characteristics that are unavailable via traditional door building methods but still retain the look and feel of a traditional stile and rail door. Specifically, they are looking for a stile and rail door that is impact resistant, insulated for both sound deadening and climate control, and of course guaranteed for 50 years. Sing Core accomplishes this by building the stile and rail face on top of a patented warp-free core.

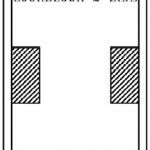

Large Thin Stile and Rail Framed Doors

Sometimes the architectural door specifications are unusual, like this wood-framed traditional stile and rail door with a large glass lite opening. This is a 14 foot tall door that calls for only a three-inch wood stile and rail surround to hold the glass. This is unusual and would be hard to accomplish with standard door building methods, and it was even a challenge for the True Flat Team, which led to their creating a new type of stiffener, which is now patent-pending technology. Now, standard stile and rail doors made with Sing Core stiles and rails can be guaranteed to remain warp-free for 50 years using new patent pending Sing Core stile and rails.

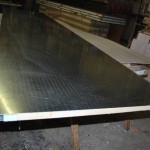

20-ft Span Wood Stave Garage Door

This is just one example to the many kinds of garage doors that Sing Core has helped to make possible. In this case, the architect insisted on 20-ft spanning warp-free wood stave planks, that any other way would have been impossible. 50 years from now, will be just as straight and true as freshly installed thanks to Sing Core and their long-span wood stave planks.

|

CNC Carved Doors

These beautifully CNC carved doors would be impossible to keep straight as they are accentuating the wood’s natural grain which is already trouble brewing, if not for the warp-free Sing Core working hard behind the scenes, deep inside to keep these doors perfectly and truly flat even though they are 107-inches tall using Sing CNC door carving blanks.

|

|

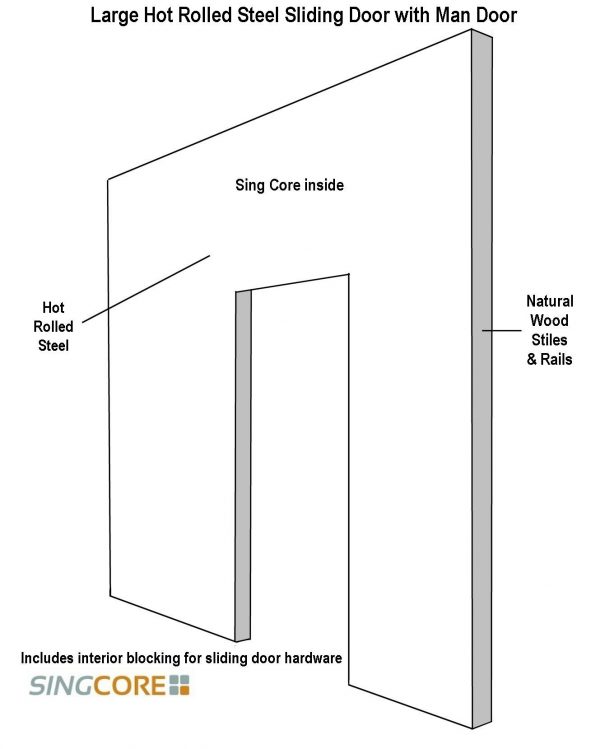

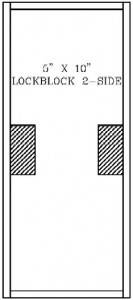

Large Sliding Doors with Man Doors

When it comes to large sliding doors with man doors, there is really only one way to do it with a high degree of precision. The large sliders with man doors must remain decidedly straight and true in order for the man door to operate seamlessly, plus, because there is Sing Core inside, you get the added benefit(s) of getting lightweight, high strength, fully insulated for sound and climate control, and our 50-year warp-free guarantee.

|

|

|

Billionaire’s Exotic Home Doors

These massive natural teak doors have Sing Core inside to keep them from warping and also to provide added protection from outside interferences to privacy and the elements. Not everyone can have their whole homes fitted with Sing’s doors, but what a great feeling it is having done so with Sing’s billionaire home doors.

|

|

|

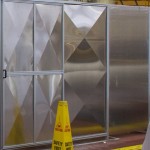

Hot Rolled Steel Doors

Hot rolled steel doors can be a challenge, especially if they are very large. Normally, large hot rolled steel means a lot of weight needs to be articulated adding stress and strain to the frame, hardware, and structure if used very often. Patented and patent-pending Sing Core reduces the weight greatly while enhancing the door’s characteristics enabling one to install a man door or open and close a mammoth-sized hot rolled steel door easily.

|

|

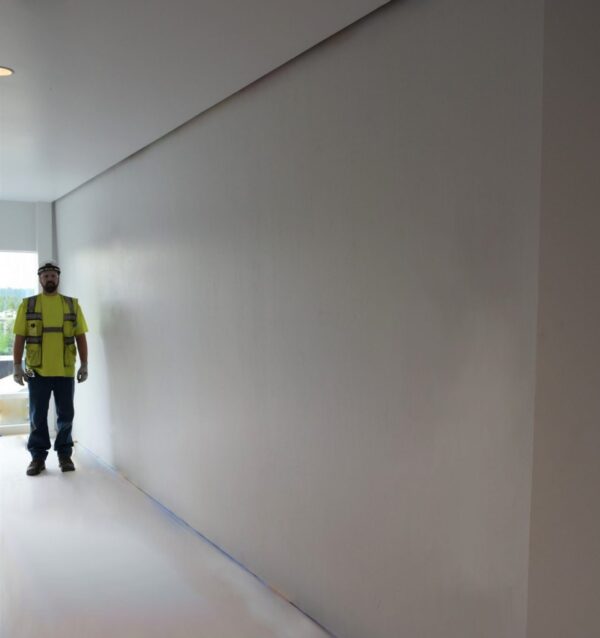

When Bigger is Better

Thanks to the patented and patent-pending technologies in the hands of the True Flat Team at Sing Core bigger does not necessarily have to mean heavier or big troubles are ahead. With Sing Core inside your big doors can be lightweight, high strength, fully insulated, and guaranteed warp-free for 50 years.

|

|

|

If you would like to know more about how to design a door with Sing Core inside, click here.