If you approach the most prestigious millworks in the world and ask them how to make the best high-end veneer doors in the world, you are likely to receive a response which references Peter Sing’s patented and patent-pending veneer door technologies and his Master Quality Door Veneer Surfaces.

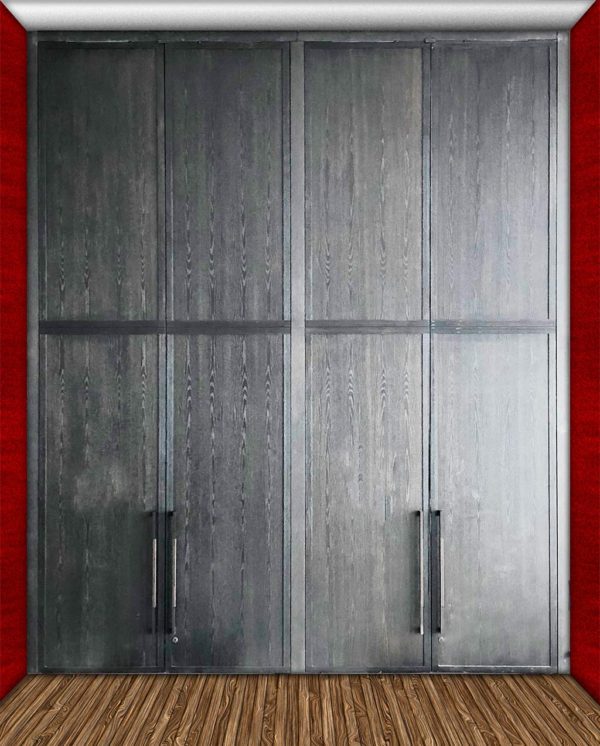

9 ft Tall Oversized Exterior Walnut Veneer Door 50 yr Guarantee

Wood veneer doors are growing in popularity due to the design features which are available in matching grain orientation on the faces of the door. The most popular orientation is called “book match” which orients leaves of veneer opened alongside each other in alternating pairs, like opening a book, where the left leaf mirrors the leaf on the right.

Book matched veneer doors are followed by “slip match” veneer doors, where the grain orientation of the leaves all face the same direction alongside one another.

There are other types of veneer matching which includes “end match,” where veneer leaves are mirrored end to end, “reverse slip match” which alternates veneer strips flipped end to end, which greatly reduces any mirroring effect, producing a more natural result. “Random match,” which shuffles all the pieces and creates a more unique succession of veneers placed side by side.

Then, there is “blueprint” which is sequential veneer from a single source to cover an entire area. Complete rooms are the most impressive when they are blueprint veneered. Some jobs include matching blueprint door skins as well. Proceed with caution, making sure there is enough source material to complete the job, and there is no room for mistakes.

Beyond these veneer matching options; special matches can be made to create a desired artistic result for high-end architectural veneer doors.

These matching capabilities are unique to veneer because veneer is sliced so thin that there is grain duplication which can be matched or mismatched according to an artist’s or designer’s vision.

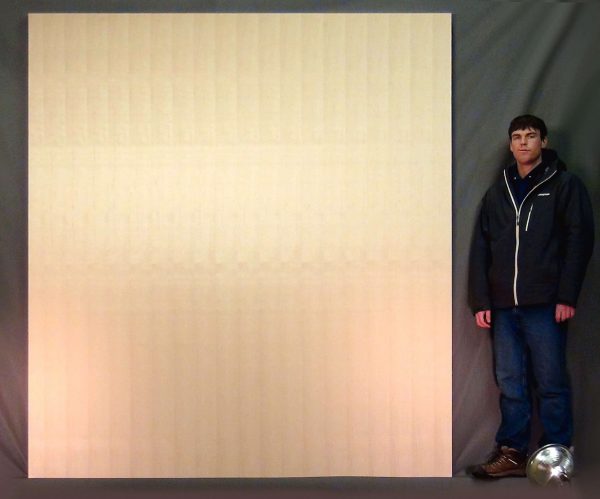

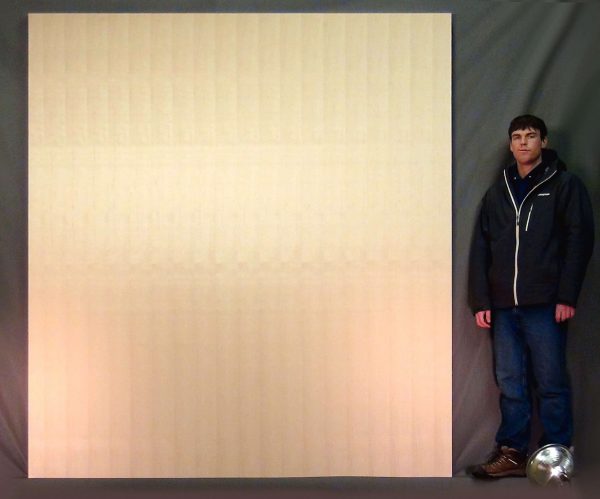

High-end Large Alt-matched Walnut Wood Veneer Door

Veneer Door Problems

When tasked with bringing a veneer door to life, the production team can run into problems associated with building veneer door as specified while achieving high precision high-end results which the most demanding exclusive door clients find highly desired and valuable.

1. Perfectly Smooth Veneer Problem

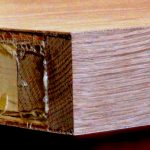

High end veneer doors need to be perfectly smooth. Because the veneer skins are so thin, you will notice “telegraphing” on the skin surface. The term telegraphing refers to essentially the bleeding-through of any of the under-laying surface, which will impact the viewable surface area of the veneer.

If you apply veneer directly to a plywood surface, for instance, in the right light, you will be able to see the terrain of the plywood through the thin veneer.

In large doors, it can be extremely difficult to find a large enough piece of smooth underlayment material, so if there are seams in the material under the veneer, this would also telegraph through to the surface.

One way to achieve a perfectly smooth surface is to use LVL (which is commonly used by most standard door manufacturers underneath wood veneers) or MDF which are smooth but heavy, and both are limited in size availability. So, if your high-end veneer door is oversized (over 4 x 8 or 5 x 10) it can be impossible to find a single seamless product.

2. High Precision Veneer Problem

High precision is a moving target when approaching the design and production of a veneer door. The surface material may be elegantly fashioned, but if the product which the door is made out of has a tendency to move, then you could be in trouble when the door warps, causing inconvenience and potentially expensive regular maintenance and repairs in the field over time.

Due to the nature of standard door building technologies, the AIA allows for ¼” variances for a 7 ft. span of a door. Door manufacturers and door hardware manufacturers allow for these variances in mounting and hardware. If a door exceeds movement over ¼” along any 7 ft. span, the result is a warped door, which can easily be compromised or fail altogether.

White Oak Veneer Pivot Door 50 Yr Guarantee

Veneer Door Solutions

Thanks to Peter Sing’s True Flat Team, you can have your high-end veneer door problems solved in a way that increases your credibility as you deliver the highest results imaginable with your most particular high-end clients.

1. Perfectly Smooth Veneer Solution

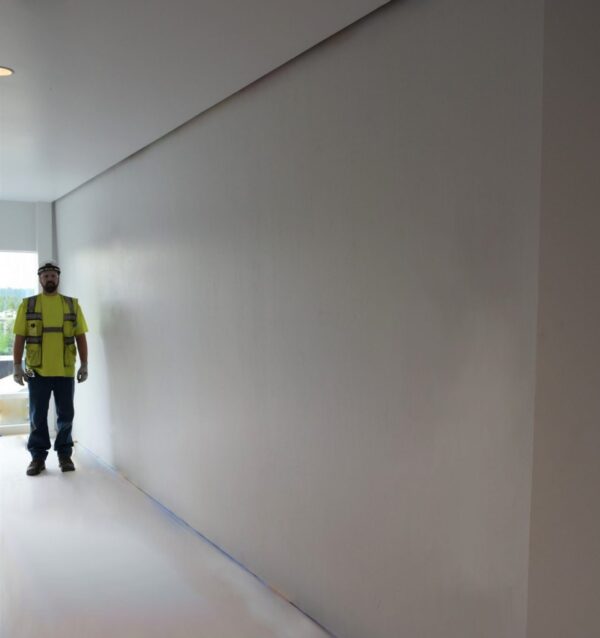

Sing’s True Flat team works hand in hand with your favorite door manufacturer, millwork, or custom door manufacturer to provide a perfectly flat, smooth surface for applying your favorite veneer to.

For years, Sing’s factory located in the pristine pacific Northwest in Washington State, has been providing the biggest and best door manufacturers in the world with large smooth surfaces for applying veneers for wood doors. Sometimes Sing’s factory applies the veneers, and in other cases Sing only provides the substrate in the form of door blanks to which the door companies apply their own veneers to.

Seamless technology. Thanks to Sing’s patented veneer door core, his factory is able to provide a perfectly flat surface hosting undetectable seam(s). While seams may be unavoidable due to the large size or a particular door, Sing has the patented technology to create an unfinished door blank veneer substrate that will not move, period.

Once the substrate is prefinished and primed, seams are undetectable. While this may be of concern for other veneer door substrates, such as LVL or MDF, this is not a problem for becoming detectable later, because Sing’s veneer door substrates are built not to move, at all.

2. High Precision Veneer Solution

Sing’s patented veneer doors core substrate is built to the highest precision standards (+/- .006 in. tolerances) which means a lot to those special clients who have the highest expectations (like military, science, technology, and aerospace industries). Why not deliver this same high level of precision to your clients who deserve the best?

In fact, Sing’s veneer door blanks, whether they are pre-skinned with wood veneer or veneered by your favorite door building professional, are guaranteed not to warp, bend, twist, cup, or otherwise fail for 50 years.

Warp-free Maple Veneer Pivot Door 99 x 87 x 1.75

50-Year Warp-Free Guarantee

Sing’s veneer door blank core substrates are such a massive improvement to previous veneer door building technologies he builds his veneer door substrates to last for centuries, but guarantees each one to 50 years of fail free operation, including warpage, and full structure warranty, including veneer lamination, if his company provides the veneer lamination.

“No other company could do it!”

… is what the biggest door manufacturers in the world say, and that’s why their doors, at least their custom big veneer doors have Sing Core inside. Just like the tallest doors in the tallest building in the United States of America at One World Trade Center, your doors could reach new heights in veneer door manufacturing backed by the only 50-year Non-warp and Structure Guarantee.

How Can I Get a Sing Veneer Door?

Admittedly, says Sing, “We don’t build doors,” as they only provide the best materials to the door companies, millworks, and high-end custom door manufacturers to build the best doors. So, if you want a Sing veneer door, all you have to do is to contact your favorite door manufacturer and tell them you want, “Sing Core inside,” your veneer door.

Then Sing and his True Flat Team will work in concert with your people to provide you with the best veneer door in the world, guaranteed for 50 years.

See also: The Secret Disclosure of Non-warping vs. Veneers Revealed

Veneer Door Photos