Imagine being able to build a torsion box work table – or anything, for that matter – without the time, energy and cost of building the torsion box yourself?

Q: How easy is it to work with?

A: Just use your normal wood working tools and treat it just like you wood any other piece of plywood.

For years, inventor Peter Sing has been providing the military, high-end millworks and architects across the USA (see clients list) with massive torsion box structural panels that are lightweight and stronger than steel pound for pound.

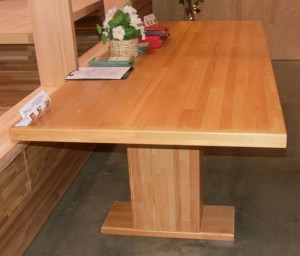

The most experienced woodworkers agree that torsion box is the answer to hand-crafting a large wood, straight, structurally-sound table while having some control over the overall weight and responsible use of natural materials.

The most experienced woodworkers agree that torsion box is the answer to hand-crafting a large wood, straight, structurally-sound table while having some control over the overall weight and responsible use of natural materials.

Sing’s invention revolutionizes the torsion box industry by tweaking the entire torsion box concept combining wood craftsmanship and space-age technology in his factory located in McCleary, Washington, cranking out solid torsion box panels that are proudly made in the USA for his upscale clientele.

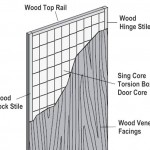

Discerning wood workers who are called upon by designers and owners of multi-million-dollar homes face challenges especially when it comes to oversized big doors. While there is no doubt experienced wood workers can make the most beautiful wood doors for their discerning clients, invariably the doors fail if they are large in size due to the inherit nature of the wood itself.

Wood will move and adapt to temperature and moisture causing it to move, compromising the functionality and seal of the most elegant hand-crafted wood door. Diligent woodworkers have sought out sing’s solution to the oversized wood door.

The same scientific solution of reinforced torsion box applies to tables and other structures that can be built without traditional wood framing for furniture or stick-built homes.

Why Torsion Box?

Because other methods of building a table top are basically inefficient. For instance, a table top built of a solid material will shift and move over time compromising its degree of flatness. Also solid materials that are less likely to move are extremely expensive, heavy and would only be considered for a permanent fixture.

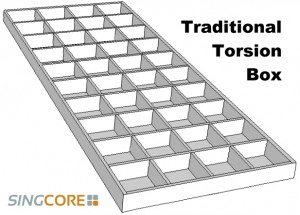

The torsion box table top design gives as flat a surface area as possible while reducing the weight of the table top due to the hollow areas in the center of the boxes. Using a torsion box design, a craftsman can build the most flat surface using 1/10th the solid material.

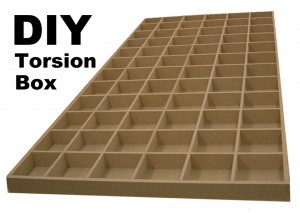

How do I build a torsion box table top?

Materials needed: Wood for exterior frame, plywood for interior framing, saw, carpenter’s wood glue, cold press (with weight or clamps), meticulous measuring ability, focus, diligence and good minor motor skills.

Materials needed: Wood for exterior frame, plywood for interior framing, saw, carpenter’s wood glue, cold press (with weight or clamps), meticulous measuring ability, focus, diligence and good minor motor skills.

Basically, you will need to establish the perimeter of your table top with an exterior frame according to the dimensions of your table. This exterior frame is generally made of wood.

The frame is built atop an underlying exterior surface material, most commonly, plywood (many varieties abound).

The most common torsion box material is plywood.

Building wood-framed boxes within the exterior frame wall-to-wall comprises the torsion box grid.

Once your torsion box structure is complete you can adhere top and bottom exterior plywood (referred to as stress skins) to complete your torsion box design.

Is it the perfect torsion box?

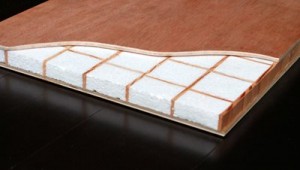

Probably not. The problem with traditional torsion box is that there is little or no shear strength, so if the structure is strained with enough horizontal torque the boxes could be compromised causing it to collapse. Plus, being made of wood still invites the base materials to move and give when adjusting to temperature or moisture in the environment.

How to build a better torsion box?

Inspired by traditional torsion box and using his experience gained in the aerospace industry, inventor Peter Sing created a better torsion box.

Inspired by traditional torsion box and using his experience gained in the aerospace industry, inventor Peter Sing created a better torsion box.

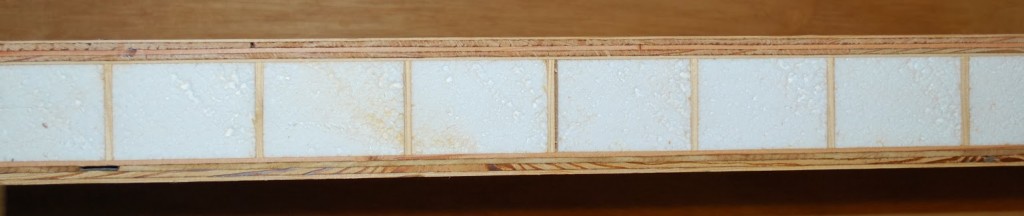

Materials needed: Wood frame, plywood strips (with grain oriented vertically as opposed to horizontally as used in traditional torsion box), saw, cold press, high-end waterproof formaldehyde-free glue, recycled dense foam that can be precisely cut into boxes.

Here’s how you build a better torsion box:

Start with your wood frame atop a stress skin, just like you would in the traditional torsion box example. This time run your plywood strips three inches apart, side by side, along the length of your exterior frame. (At this point it looks like you might be having mice race for the cheese at the other end, but keep your money in your pocket; there are no mice here.)

Start with your wood frame atop a stress skin, just like you would in the traditional torsion box example. This time run your plywood strips three inches apart, side by side, along the length of your exterior frame. (At this point it looks like you might be having mice race for the cheese at the other end, but keep your money in your pocket; there are no mice here.)

Now, place your 3 inch foam cubes between the vertical grain rails. Insert a 3 inch bumper (or stile) to close off the recycled foam completing your first row of interior boxes. Then place another 3 inch foam cube, followed by another bumper. Repeat until the entire interior area is filled wall to wall.

Adhere top and bottom exterior skins and you’re done.

Congratulations; you’ve just built the best torsion box structure ever!

How could you make it even better?

You’ve got to admit, as effective as it is, the tedious process is not only time consuming but expensive. But what if…

What if you didn’t have to build the torsion box structure at all?

What if you could buy Sing’s torsion boxes already pre-built for you?

That’s right. Mr. Sing’s factory is cranking out his patented torsion boxes by the truckload, and he’s offering special pre-built torsion box implants that measure 48 in. x 24 in. x 1.5 in. complete with stress skins for you to cut to size, drop into any frame for the perfect torsion box strength and lightweight design.

Sing Torsion Box is fast, easy, affordable, solid, lightweight, stronger than steel pound for pound and environmentally responsible.

How to I use Sing’s pre-built torsion box?

It’s easy to build your own products on demand, as you need it in any size you want.

It’s easy to build your own products on demand, as you need it in any size you want.

This is the most popular in-house Sing technology used by craftsmen and millworks.

You might have never known how easy it is to build using this cold-press drop-in method.

How Easy Is It?

This is how simple it is to for you to use our pre-built torsion box.

All you have to do is to coat the underside of your bottom skin with regular carpenter glue…

Place your wood edges atop the glued-side of the skin…

Then fill the void with pre-built torsion box pieces until full.

Place glued top skin onto your completed work…

Finally cold-press until dry.

It’s that easy: Congratulations; you just made your own insulated reinforced torsion box panel!

$50 to Share Your Sing Project with Sing Core

Submit a copy of your receipt along with drawings and photos of your project built with Sing Sandwich. If we feature your project on our web site (singcore.com) you will receive a $50 cash reward for sharing your project (with your name and full credits) to help make the world a better place. You will also receive a certificate recognizing and honoring your sustainable efforts.

Submit a copy of your receipt along with drawings and photos of your project built with Sing Sandwich. If we feature your project on our web site (singcore.com) you will receive a $50 cash reward for sharing your project (with your name and full credits) to help make the world a better place. You will also receive a certificate recognizing and honoring your sustainable efforts.

Details, photos and instructions compliments of Lightweight University.