Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.

Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.

In the past, very large and oversize specified doors were often made as a single piece and shipped whole to the contractor for installation. This is particularly true of very large pivot doors and sliding doors. With modern door construction techniques pioneered by Sing Core large doors can be produced and shipped to the customer in several pieces. These segmented doors pass on savings to the customer while maintaining the highest quality standards for warp free door construction.

Benefits of Modern Segmented Door Construction

Building a door in sections provides numerous benefits without compromise in strength, lightness, and flatness:

See Them Come Together

More Efficient to Build

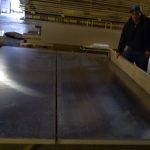

Constructing a door in smaller sections makes the door easier to handle in the factory and easier to produce in general. Having more manageable sections leads to quick and efficient construction, at a cheaper cost. Doors constructed with our modern sectional approach pass on savings to the customer.

Cheaper to Ship

Doors cores produced in sections are built to be convenient and cheap to ship compared to a door built in one piece. This may reduce shipping costs payed by the customer to receive their door purchase.

Easier to Handle

Very large doors constructed in segments conform to common sizes. When you receive the door at your site handling it in segments is usually more natural for workers used to traditional sized doors than and 4×8 materials than handling an extra large door. Leaving joining the door until it reaches the site cuts costs and saves time all the way from our factory to your building site.

Very large doors constructed in segments conform to common sizes. When you receive the door at your site handling it in segments is usually more natural for workers used to traditional sized doors than and 4×8 materials than handling an extra large door. Leaving joining the door until it reaches the site cuts costs and saves time all the way from our factory to your building site.

Strong and Stable

Sing Core doors shipped in sections and assembled on site maintain the highest standards for strength, lightness, and straightness. At Sing core we guarantee warp-free performance of segmented doors for 5 years.

How to Assemble a Sing Core Segmented Door

Assembly of a modern sliding door constructed using Sing Core technology without any specialized tools and equipment.

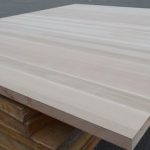

1. Lay Each Panel Flat

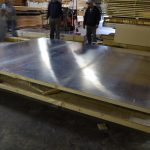

The first step to join a Sing Core sectional door is to lay the panels on a flat surface. Any flat clean surface will work. For very large doors we like to use two straight beams laid on the ground along to hold the top and bottom of each door segment.

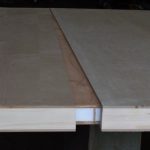

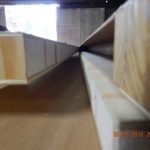

2. Slide a Spline in to One Side

Each spline and pocket are precisely cut to fit with strength. Our products are built with our 5 year warp-free guarantee in mind. Simply push or lightly hammer the spline in place on one side of the joint. Then your panels are ready to be fit together.

3. Joining the Panels

The final step in joining a modern sliding or pivot door is to press the sides together. This can be accomplished a variety of ways, including gentle application of a sledge hammer, a few ratchet straps, clamps, or any other means you have of providing joining force. Once joined, the door is strong and secure, built to last, and can be finished and installed as any other Sing Core door.

How to Build a Modern Door

- Modern Sliding Door Sections stacked for easy shipment