Sing Core is moving into the arena of the visual arts empowering artists to further express their uniquely fashioned visionary concept to 3D manifestations.

The physics of the three-dimensional world in which we live often can create challenges for the creative artist in the engineering process of bringing their creations to life so they can be displayed and appreciated by others.

The mass and material components of the masterpiece may prohibit the execution of the objet d’art because materials which exist outside a vacuum will move according to changes in the environment where they are displayed.

This movement could compromise the artistic rendering causing the project to deconstruct or fail. This would be a tragic conclusion to any artist’s work, though it is common for œuvres d’art to need regular maintenance over time to minimize the effects of aging over the years.

You want your art to be manufactured in such a way as to preserve it in its entirety over time, so that you can have an opportunity, not unlike that of Jeff Koon who sold his metallic balloon animal dog sculpture for 58 MILLION DOLLARS which is on display at the San Francisco Museum of Modern Art.

The overall weight of a sculpture of large proportion will often present problems associated with how heavy the projet d’art is when it is completed.

Overcoming the challenges facing artists representing the limitations of the physics of materials is what Sing Core specializes in. And the bigger the project, the more important it is to have Sing Core inside to maintain the structural integrity of your artistic expression.

Is it an I-beam, or is it a 30 ft. long table, which in itself is a high concept work of art made of steel with Sing Core inside.

Steel is a crystal. Not a pretty translucent crystal, like diamonds or rubies, but poly crystals bonded together in haphazard fashion which is perfect in its imperfection. Crystal steel, the perfect method to represent the melding of something old and something new giving birth to artistic creations.

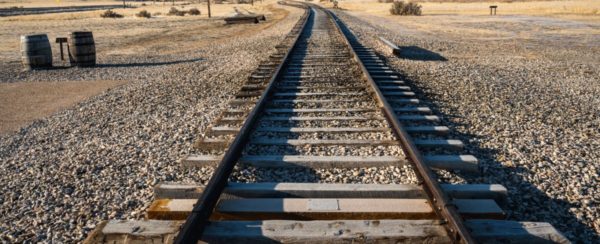

Connecting two or more completely different ideas, one with the other, to create and bring to life an entirely new re-imagined conceptual work of art is what Sing Core is all about. Sing Core is not unlike the transcontinental railway.

Not since 1869 has there been such a unique system of joining two ideas together, like linking the East with the West. Today Sing Core is the bridge bringing together industry and art.

Sing Core is an invention of artiste visionnaire, Peter Sing, who created the unique lightweight substructure material which counteracts the surface material’s tendency to move, expand and contract, thereby maintaining the sculpture’s structural integrity over time.

Sing’s invention is based on his patented reinforced vertical grain torsion box which is changing the way all kinds of things are made.

Here you can see inventor Peter Sing standing on a one-inch aluminum panel 13-feet long suspended between two sawhorses with little or no deflection. If this panel did not have Sing Core inside, he would be standing on the ground. This is just one example of how strong Sing’s core is.

It is not uncommon to find Sing’s core inside large ceramic and/or glass art projects simply due to its extraordinary high precision at +/- .006 in. and superior strength at 660+ PSI.

Peter Sing’s demonstration of his “unbreakable mirror,” which may inspire you to build an entire home made of mirrors.

Here’s a mosaic table art project which was created atop Sing’s substrate foundation:

You will find Peter Sing assisting in art projects around the world where his Sing products may not only be inside artwork, but displaying the artwork as well.

Sing’s museum display panels and modular art gallery panels are among the most popular in the world today.

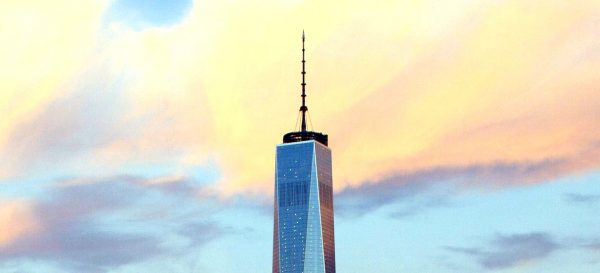

There’s a reason why Sing’s patented solution reaches the highest door height in America as featured inside the tallest doors in the tallest building, One World Trade Center’s Freedom Tower, and you will find it from beneath the depths of the sea (US Navy) to outer space (NASA).

The reason is the common answer,

“There was no other way to do it.”

Yes, there are many applications where Eco-friendly Sing Core accomplishes what no other building material in the world could do, especially in terms of weight, strength, and dimensional stability. No other material can do what Sing Core accomplishes.

And if you’re looking for places to accommodate visitors outside your establishment think about the possibilities of having a lightweight high strength aluminum bench with Sing Core inside for a nearly indestructible presence which looks and feels like a massive piece of solid metal, but as you can see, is being easily carried by inventor Peter Sing.

Sing Aluminum Bench

Weather your using these impressive industrial strength metal benches indoors or outdoors, just because your benches are light in weight, it doesn’t mean they are weak, as you might think, because Sing’s benches really are stronger than steel pound for pound.

Independently tested at the University of Washington, Sing’s core boasts a PSI of 660 pounds per square inch rating, in comparison to other lightweight core materials which range from 10 to 110 PSI.

Sing’s weatherproof aluminum benches are built to last centuries whether they are used in exterior applications of indoors.

50 Yr Warp-free Guarantee

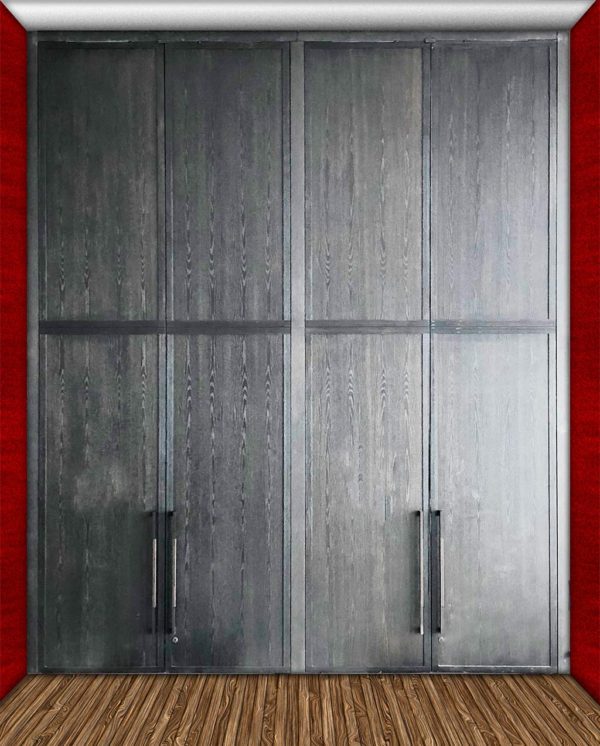

The most popular application for Sing’s core is doors, especially in the large door industry, as there is no way to build a huge door which can be lightweight, yet stronger than steel pound for pound. Mr. Sing is so confident about his large door building capabilities that he can guarantee his big doors not to warp or fail for 50 years!

You never know where you might find Sing’s core, but you might be surprised to find complete homes built of Sing Core, as well as high functioning Sing Furniture. That said, entire homes, and all their furnishings could have Sing Core inside.

- Sing Core nightstand

- Sing Core Armoire

Contact Sing Core for more information.