Sandwich Panel

Sandwich Panel

Sing Core’s patented green-building material is realized in the Sing Sandwich Panel that increases the strength of the Sing Core by completing the torsion box design. Need more strength? By increasing the thickness of your Sing Sandwich panel by two, the strength is multiplied by four. Four times the strength at very little added weight.

Sing Sandwich Panels are an open-ended Sing Core base sandwiched between two aluminum or wood skins without solid wood or any other material along 4 sides of edges. (See photo to the right.)

Each Sing Sandwich Panel is made of Sing core with wood base skins used as filler. Our Sing sandwich Panel is designed to protect Sing core with wood base skins providing a better bonding surface for adding solid wood block, solid wood edge and final skin resulting in a completed Sing Core Panel.

Standard Sing Sandwich Panel Dimensions:

- dimension: 12 inch x 48 inch to 4 ft x 8 st

- thickness from 1/2 inch to 6 inch.

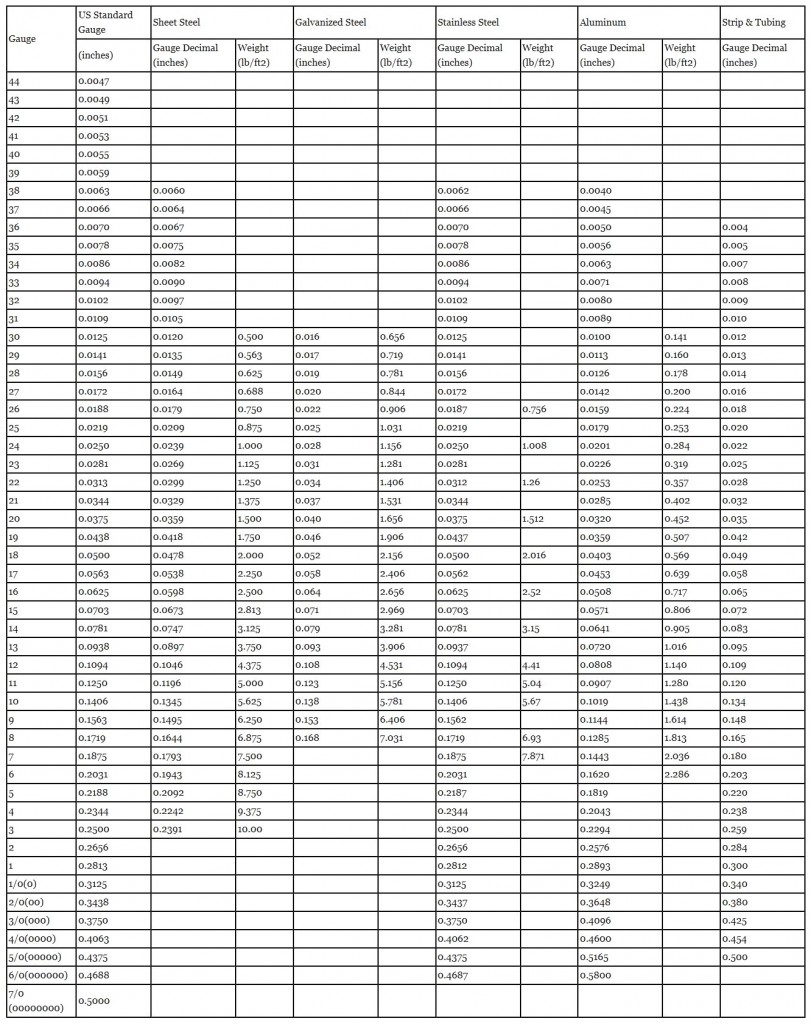

Sing Sandwich Panel Skin Option Examples:

… just to name a few, as the possibilities are limited only to any available flat building material.

Applications of Sing Sandwich Panels:

Use as sandwich panel block to drop in any solid wood frame, inbetween two sheets of plywood or any skin materials and cold press with adhesive (in most cases regular carpenter glue will work if it is a wood based skin) to build Sing Core Panels or any other type of Sing products. The applications are virtually unlimited!

Versatility

Remember, Sing Core technology is completely customizable to your specifications as they are available in any length, any width and any thickness and bonded to any exterior finish.

We are so certain that Sing Core is the solution to your green building challenges that we offer a 100% refund for any prototype order, for those who want to test drive any form of Sing Core products for use in their applications, so you have nothing to lose. Click Here for our convenient online order form.

See also: Sing Core, Sing Plywood/Panels