Sing Aluminum honeycomb panels are different than other traditional-style aluminum honeycomb panels, though visually they appear to be identical. Sing Aluminum honeycomb panels are based on the patented Sing Sandwich panel technology that produces an aluminum-clad panel that out performs any other panel material in terms of lightweight, high strength and is also Eco-friendly.

Sing Aluminum honeycomb panels are different than other traditional-style aluminum honeycomb panels, though visually they appear to be identical. Sing Aluminum honeycomb panels are based on the patented Sing Sandwich panel technology that produces an aluminum-clad panel that out performs any other panel material in terms of lightweight, high strength and is also Eco-friendly.

Compare Sing Aluminum Honeycomb Panels

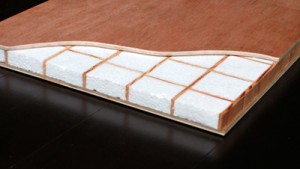

When comparing Sing aluminum honeycomb panel to other aluminum honeycomb panels, you must start at the core of the panel. Traditional aluminum panels have a honeycomb core that could be made of aluminum, plastic, cardboard or paper material that provides more rigidity than a hollow core panel which would be extremely flimsy.

Sing Honeycomb Core

Sing Honeycomb Core

Sing Aluminum panels start with a vertical wood grain torsion box core (a handcrafted woodworking technology that has been around for thousands of years) that in itself is extremely strong and rigid. The next step is to bond to what would otherwise be empty voids within the torsion box honeycomb core a lightweight strengthening material (recycled foam) wall-to-wall using formaldehyde-free glue.

While traditional aluminum honeycomb panels may test-out at ten-to-110 PSI, standard Sing sandwich panels start at about 660 PSI and can be upgraded to meet your specific requirements. The resulting Sing honeycomb panels are literally stronger than steel pound-for-pound as confirmed by independent testing at the University of Washington.

Lightweight Panels

Lightweight Panels

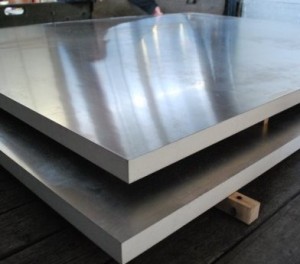

Architects, designers and high-end millworks around the world are reaching out for alternatives to existing lightweight panels that have little strength, are easily damaged and deteriorate over time. Sing lightweight panels compare in weight to other honeycomb panels for sale including plastic honeycomb panels, fiberglass honeycomb panels and cardboard honeycomb panels but only Sing honeycomb panels have the strength and structural integrity to sustain long spans without fail or compromise.

How Versatile are Sing Honeycomb Panels?

Being able to have high value and performance and solving structural issues that have plagued architects, designers and artisans for centuries – especially when confronted by the structural limitations of conventional building materials – is why you will find Sing honeycomb core lightweight panels at NASA, throughout the aerospace industry and used by the United States military.

Being able to have high value and performance and solving structural issues that have plagued architects, designers and artisans for centuries – especially when confronted by the structural limitations of conventional building materials – is why you will find Sing honeycomb core lightweight panels at NASA, throughout the aerospace industry and used by the United States military.

Sing Honeycomb Panels for Furniture

Sing honeycomb core lightweight panels are world famous for high-end large doors, oversize aluminum honeycomb panels, post and beam and various building applications; it may surprise you that one of the most high-growth applications of this newly invented, patented technology is amongst the furniture industry as they are increasingly using Sing honeycomb panels for furniture building.

Earth-friendly Sustainability

Sing Core is one of the only honeycomb panel manufacturers that have a commitment to Earth-friendly sustainability manufacturing all Sing honeycomb panels, here at home in the USA and exporting to other countries.

Sing Core is one of the only honeycomb panel manufacturers that have a commitment to Earth-friendly sustainability manufacturing all Sing honeycomb panels, here at home in the USA and exporting to other countries.

Where are Sing honeycomb panels for sale?

Sing honeycomb panels are available at your favorite lumber yard or regular aluminum honeycomb panel suppliers.

How do I get a honeycomb panel price?

It’s easy to price your Sing honeycomb panels by visiting your regular retail outlet, or if you are a wholesale account, our simple online pricing method only requires that you know the length, the width and the thickness of the honeycomb panels that you want, making it convenient for you to estimate or bid using patented Sing honeycomb core panels.

It’s easy to price your Sing honeycomb panels by visiting your regular retail outlet, or if you are a wholesale account, our simple online pricing method only requires that you know the length, the width and the thickness of the honeycomb panels that you want, making it convenient for you to estimate or bid using patented Sing honeycomb core panels.

Fast Delivery – Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

How to Buy

SINGCORE Honeycomb Core Lightweight Panels are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity.

Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.

Choose Sing for all your honeycomb core lightweight panels! When using Sing honeycomb core lightweight panels, you design your own finished product by adding the trim, paint, and hardware. Sing honeycomb core lightweight panels are great for millwork shops, door builders aerospace and marine applications.

Great pricing is available to distributors and retailers.

**Wholesale prices available to licensed dealers/installers.

- SingCore Stays True Flat

- Even Our Metal Panels

- SingCore Movable Walls

- Sing Home walls

- LIghtweight Posts and Beams

- Sing Beams Stay True Flat