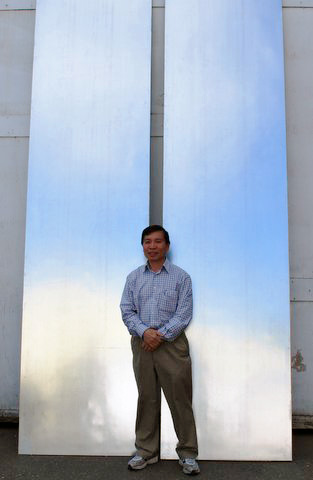

Sing Core provides architects, designers, contractors and commercial industries a new, Eco-friendly alternative to traditional metal fabrication that is lightweight and stronger than metal.

Sing Core provides architects, designers, contractors and commercial industries a new, Eco-friendly alternative to traditional metal fabrication that is lightweight and stronger than metal.

Now only $256 for a 4’x8′ sheet.

| Size | Sqft | Price |

|---|---|---|

| 4’x8′ | 32sqft | $256/sheet |

| 4’x10′ | 40sqft | $320/sheet |

| over 4’x10′ | any size | Ask for price |

Custom Sizes Available

If you have a special custom, architecturally specified, or otherwise unique requirement for your project, don’t hesitate to ask. We are experts in the unexpected, and seek to exceed your every desire. Visit our pricing page for more information and to submit your price quote request.

Known for the most prestigious wooden panels for walls and doors, Sing Core material panels offer outstanding solutions for the most challenging composite structures.

When compared to other types of composite materials, our lightweight wood panels outperform any china panel or panels of wood based product.

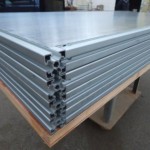

Each custom panel features our unique patented honeycomb core that can host any exterior surface material for a lightweight composite structural panel, including (but not limited to) aluminum metal or any flat metal.

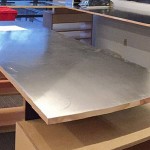

Lightweight aluminum composite panels are the second-most best selling product that Sing Core makes with high precision and performance that cannot be matched by the standard aluminum shop. Our light weight aluminum and honeycomb composite is the perfect component available in nearly any aluminum thickness for use in aluminum structures.

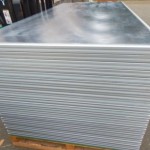

Next up, our galvanized metal panels are equally as popular as our Sing Core aluminum that exceeds any machine aluminum strength while remaining lightweight and true flat. This is the only aluminum material that can be perfectly flat and stay flat over long spans for years.

If you are ready to take your aluminum design to the next level, Sing aluminum metal products are worth investigating in your best interest, for the benefit of your clients and a better world.

- Retail office furnishings

- High precision workstations