Sing Core is proud to announce the first modular trade show display system that is lightweight, high-strength and Eco-friendly for a better world.

Trade Show Display Components

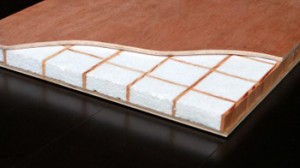

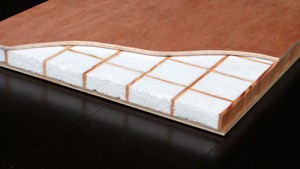

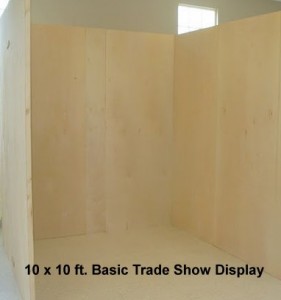

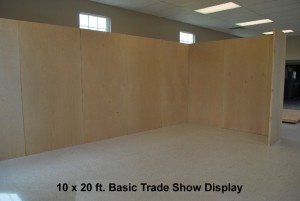

This unique material allows you to build a trade show display without requiring a 2×4 frame and is many times stronger. Even though your trade show wall will be 2 inches thick it will have the strength of a fully framed wall because the structural frame is built into each lightweight high-strength trade show panel.

Build Your Own Custom Trade Show Booth

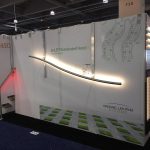

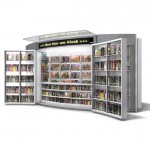

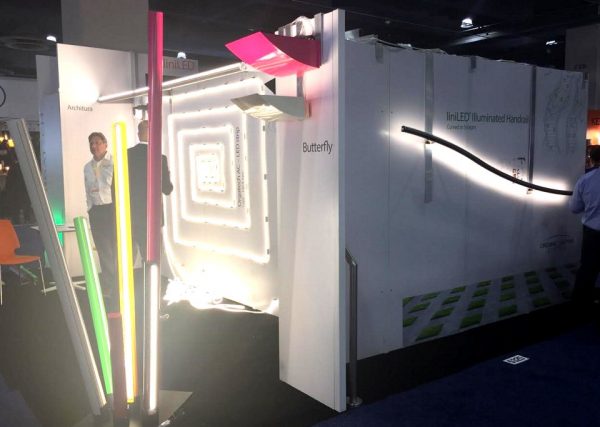

Take a look at this custom trade show booth that was designed and built by the company using our modular trade show components.

How to create your own trade show booth design system is easier than learning your ABC‘s. So, come on and do the Sing creation with me.

A. Decide what you want and the components you need

- A: Create Your Design

- B: Create Shopping List

- C: Experience the Results

B. We give you everything you need to create your custom trade show booth

C. You are proud to have the best trade show display

|

|

|

|

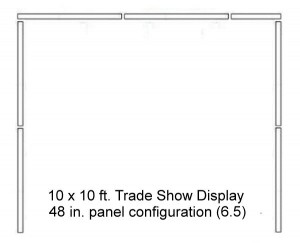

10 ft. x 10 ft. Trade Show Display Example |

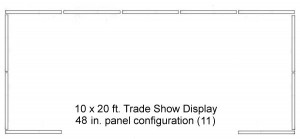

10 ft. x 20 ft. Trade Show Display Example |

|

|

Each Sing Sandwich panel can be used as many different trade show components and in a variety of trade show applications, like

| 1. track wall 2. slatwall 3. movable wall 4. partition wall 5. two story trade show booth 6. trade show floor 7. trade show roof 8. floating shelves 9. museum cable hanging shelves |

For high end custom trade show displays, Click Here.

Options include adding exterior surface materials, like any wood species, aluminum, concrete, fiberglass/FRP, galvanized steel, HPL, metal, plastic, stainless steel, etc…

Now available in affordable lightweight slatwall trade show display.

We Welcome Custom Trade Show Ideas

How to Make Your Own Design

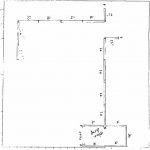

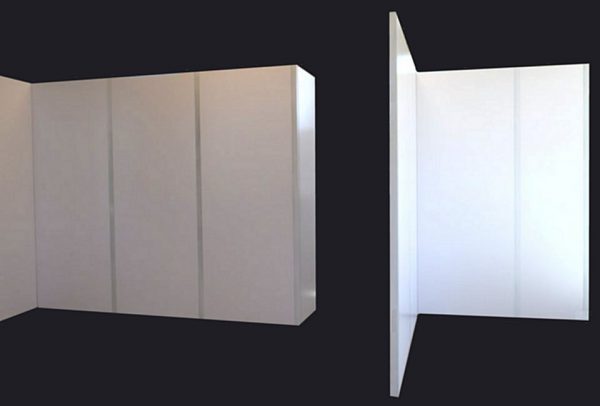

Now that you know the components, you can easily design your own custom trade show booth… For instance, you could provide us with a drawing, like this:

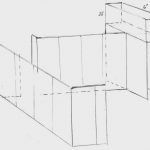

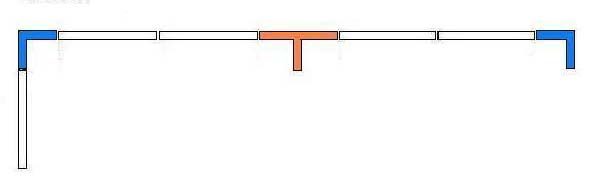

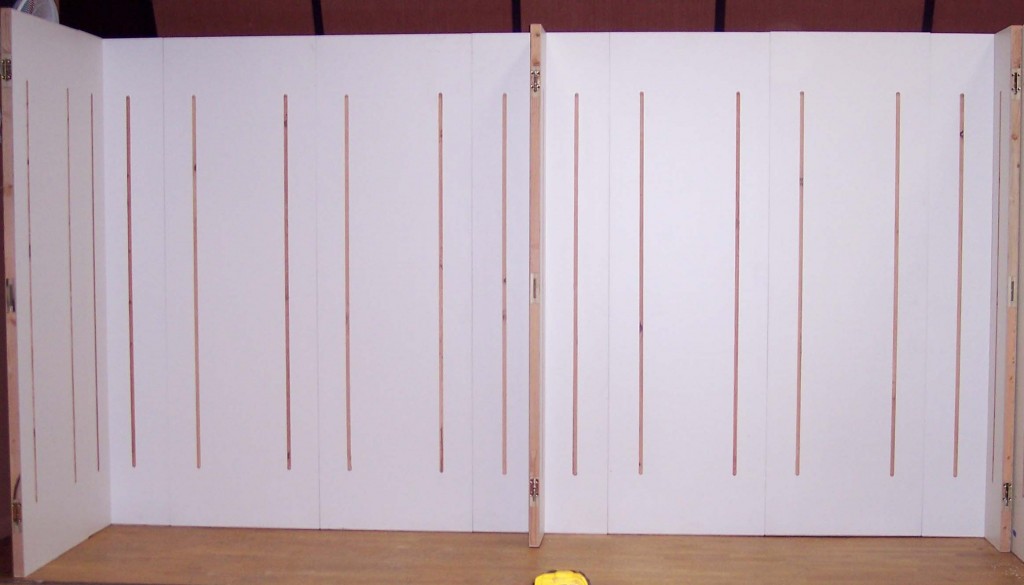

In the drawing (above) this 15 foot wide trade show booth has a left wall depth of 4 foot for display purposes. The white panels represent Sing Trade Show Panel “A,” the blue represents the Sing Trade Show Display “L” and the salmon colored Sing Trade Show “T” is in the middle. In this example, the client requested vertical grooves be pre-cut for installation of track for trade show display hardware. Sing trade show displays can be configured to your specifications. The order would reflect 5 Panel As, 2 Display Ls and 1 Display T. Here are the results:  Another example is this drawing for an implant modular office for use in a trade show display based on the customer’s drawing:

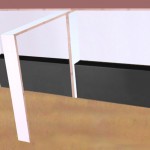

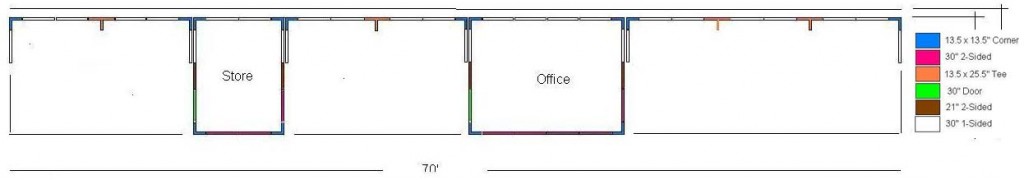

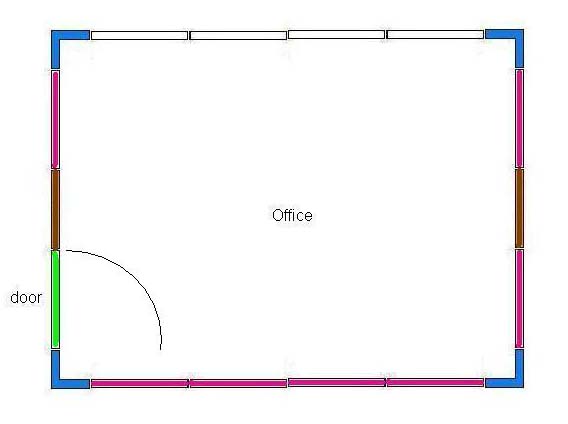

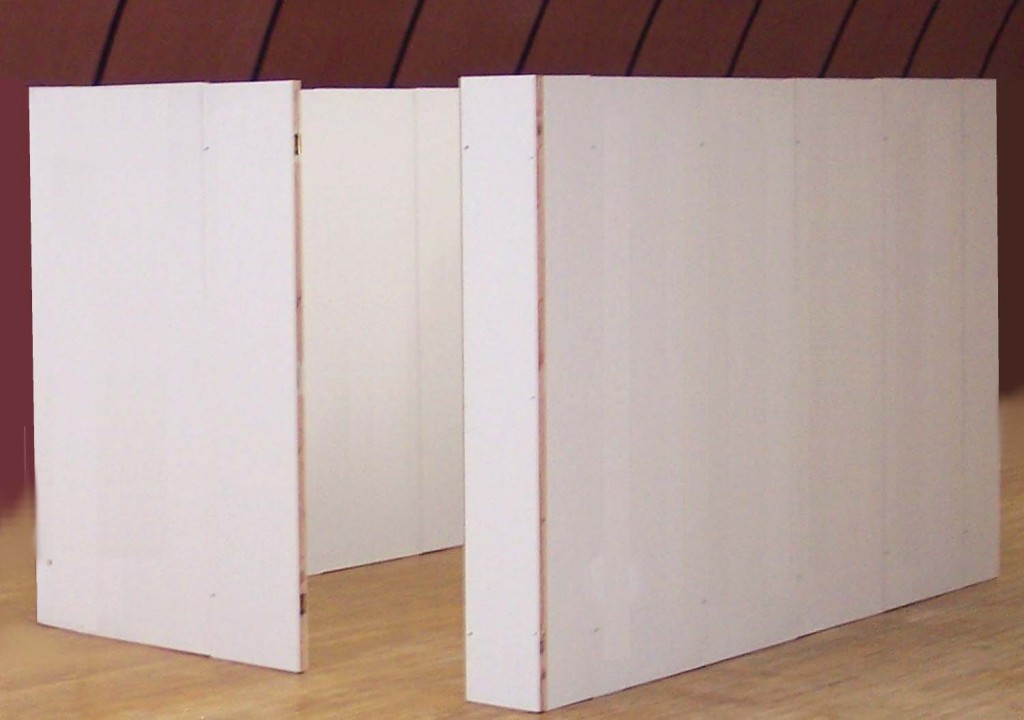

Another example is this drawing for an implant modular office for use in a trade show display based on the customer’s drawing:  The order for this office space included 7 custom (C) 30 inch magnetic whiteboard panels. This order would reflect 4 Panel As, 2 Panel Bs, 7 Panel Cs, 1 Panel D and 4 Display Ls. The resulting office space as follows was assembled in minutes with our lightweight, high strength, modular cam lock design:

The order for this office space included 7 custom (C) 30 inch magnetic whiteboard panels. This order would reflect 4 Panel As, 2 Panel Bs, 7 Panel Cs, 1 Panel D and 4 Display Ls. The resulting office space as follows was assembled in minutes with our lightweight, high strength, modular cam lock design:  Note: Prices are subject to change due to material cost and prices do not include shipping. Final price (especially in case of customized specifications) is not final until agreed to and authorized by purchaser and Sing Core. For accurate wholesale pricing, industry trade professionals are encouraged to inquire directly by contacting us direct.

Note: Prices are subject to change due to material cost and prices do not include shipping. Final price (especially in case of customized specifications) is not final until agreed to and authorized by purchaser and Sing Core. For accurate wholesale pricing, industry trade professionals are encouraged to inquire directly by contacting us direct.

For our more discriminating clients who prefer our premium trade show display components:

To see your ideal trade show displays come to life, simply design your display using our lightweight, high strength trade show components as listed below.

To see your ideal trade show displays come to life, simply design your display using our lightweight, high strength trade show components as listed below.

Once you have decided on how many panels, in what sizes and how many Ls and Ts will be in your system it is quick and easy to order online by clicking the buttons for the products that you need.

After you’ve received your Sing Trade Show Displays you will discover that assembly of your trade show displays is as quick easy as ordering.

Get the upscale trade show display wall panel components that you want:

Sing Trade Show Panel “A”

![]() They key component for designing and building your trade show display walls is our “A” trade show panels. These patented display panels measure 36 inches wide. They are lightweight and easy to handle and come complete with Frost White MDF exterior finish. 36 lbs. Panel “A”

They key component for designing and building your trade show display walls is our “A” trade show panels. These patented display panels measure 36 inches wide. They are lightweight and easy to handle and come complete with Frost White MDF exterior finish. 36 lbs. Panel “A”

Sing Trade Show Panel “B”

![]() Our alternatively-sized component for your custom trade show display walls consists of our “B” trade show panels. These patented display panels measure 22 inches wide. 25 lbs. Panel “B”

Our alternatively-sized component for your custom trade show display walls consists of our “B” trade show panels. These patented display panels measure 22 inches wide. 25 lbs. Panel “B”

Sing Trade Show Display “L”

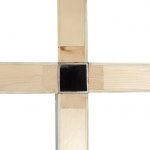

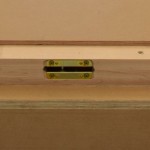

![]() The Sing tradeshow display L is the key corner component. The standard dimensions of this corner connector is 14 inches by 14 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining. 37 lbs. Display “L”

The Sing tradeshow display L is the key corner component. The standard dimensions of this corner connector is 14 inches by 14 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining. 37 lbs. Display “L”

Sing Trade Show Display “T”

![]() The Sing trade show display T is the component that joins two trade show wall panels together. As you determine your design keep in mind the dimensions as it measures 28 inches wide by 14 inches deep. The patented Sing T can be used as a wall footing to add stability over long spans or to add a perpendicular wall or add other components. 53 lbs. Display “T”

The Sing trade show display T is the component that joins two trade show wall panels together. As you determine your design keep in mind the dimensions as it measures 28 inches wide by 14 inches deep. The patented Sing T can be used as a wall footing to add stability over long spans or to add a perpendicular wall or add other components. 53 lbs. Display “T”