On the forefront of technology and promoting artistic freedom via ingenuity and creative design alternatives, Sing Core products finds itself as the foundation for many endeavors that promote the arts.

Certainly stage sets and sound stages feature Sing Core as moveable walls, platforms and stage set pieces allowing staff to quickly set-up, tear-down and reconfigure on-the-fly.

It is an honor when we see artists embracing Sing Core’s attributes and incorporating our panels, substrates, posts and beams into their objets d’art.

Set Your Imagination Free

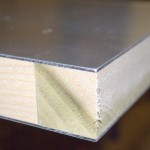

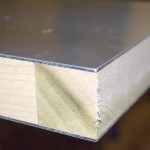

One case in point, this unique design that is a co-creative effort of Robert Brou of Naturalism Furniture and mosaic artist Rhonda Heisler:

Concrete and mosaic on the outside, Sing Core on the inside.