Looking for a millwork to finish your SingCore project?

Our primary affiliation is with the millworks that are highly skilled and qualified to deliver an end product which exemplifies the highest and best use of our patented SingCore building materials. In fact, when we receive inquiries about our products, our first question is, “Who is your millwork company?” If they do not have one they are working with, we suggest they get one and have them contact us directly.

Our primary affiliation is with the millworks that are highly skilled and qualified to deliver an end product which exemplifies the highest and best use of our patented SingCore building materials. In fact, when we receive inquiries about our products, our first question is, “Who is your millwork company?” If they do not have one they are working with, we suggest they get one and have them contact us directly.

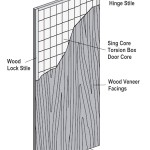

SingCore is an extraordinary building material that left to itself is not much more glamorous than any other engineered plywood, even though nothing can compare to SingCore’s unparalleled light weight and strength. Yet, in the hands of a skilled millwork, their specialized craftsmanship is what makes Eco-friendly SingCore shine with the beauty and elegance SingCore products are known for.

Millworks face many challenges when bringing the architect’s vision to life. In some cases, the limitation of available building material can render a potential job impractical or even impossible.

Click Here to Get an Estimate

Problem

For instance, a particular project might include a large wooden door. If the large wood door is an exterior door over seven feet tall or over four feet wide (as is the case for most modern pivot entry doors) millworks and custom door manufacturers will simply pass on the large door portion of the job, forfeit the entire job altogether based on the oversized exterior door, or if they do take the job may agree to build the large door according to the architectural specifications but will not offer a warranty on the performance of the big door.

For instance, a particular project might include a large wooden door. If the large wood door is an exterior door over seven feet tall or over four feet wide (as is the case for most modern pivot entry doors) millworks and custom door manufacturers will simply pass on the large door portion of the job, forfeit the entire job altogether based on the oversized exterior door, or if they do take the job may agree to build the large door according to the architectural specifications but will not offer a warranty on the performance of the big door.

Large exterior doors, especially large wood doors, are a problem because millworks and door manufacturers know the doors will fail due to warping. It’s nothing personal; it’s just the nature of the beast being the wood grain itself which tends to move according to changes in temperature, moisture or other environmental conditions.

Solution

Patented SingCore when engineered by the warp-free team can prevent any large door from failing over time. Millworks are confident they can provide a solution for any project including large doors of any size if they have SingCore inside, guaranteed.

Patented SingCore when engineered by the warp-free team can prevent any large door from failing over time. Millworks are confident they can provide a solution for any project including large doors of any size if they have SingCore inside, guaranteed.

Clients may ask for a warranty on the large doors (that without SingCore inside could not be warranted) and the millwork can now offer the professional SingCore guarantee – in writing – that the doors with professional SingCore inside are guaranteed not to warp, bend, twist or otherwise fail for 50 years.

Working with SingCore

Easy to CNC router

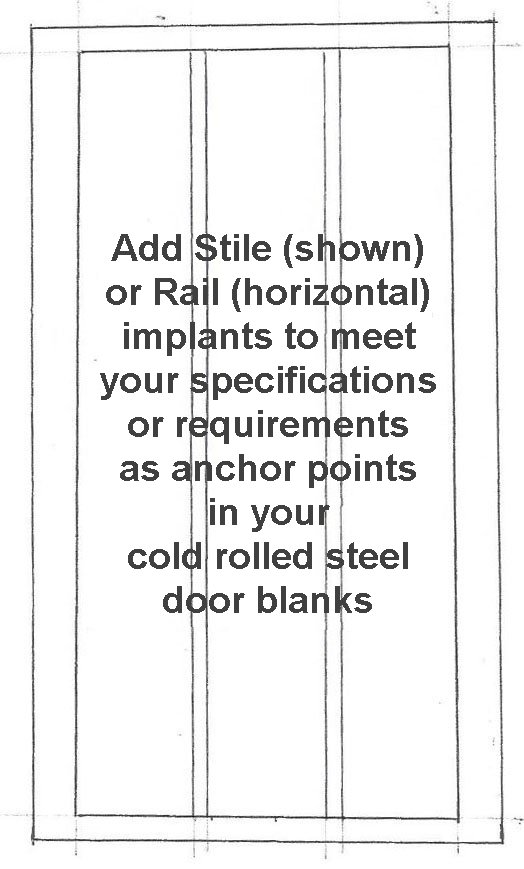

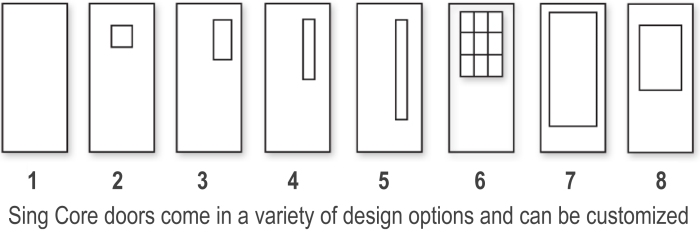

Millworks use either open edge or closed edge Sing Panel, whichever works best for the project at hand, as well as many options for skin types, solid blocking, custom lite cut outs, solid and exterior edging options.

SingCore is easy to machine and work with using traditional woodworking tools, CNC and edge –banding machinery and equipment.

Used as substrate material, SingCore can be delivered to the millwork ready for cold press or hot press lamination. Alternatively, millworks may desire exterior surfaces to be applied in our factory, which makes their job easier.

SingCore Durability

SingCore Durability

Products made of Sing panels are easy to repair damage to its original condition simply and easily by cutting a hole (you can even use a chain saw without compromising the structure due to its unique Sing Core torsion box/foam and stress skin composition). Any repairs will have the strength, integrity and durability of the original structure.

Professional Sing Panel Product

All Professional Sing products are guaranteed warp-free and structure guaranteed for 50 years. We can accommodate your specifications, just let us know your required tolerances for flatness, and Sing Core can provide the solution guaranteeing your customer’s satisfaction and your peace of mind.

SingCore Expertise

We specialize in providing solutions for high-end applications and millworks, based on the requirements of our customers, meeting or exceeding their expectations and those of their clients by using the right materials and years of warp-free solution experience. Add to that, our commitment to you, to do everything in our power to support you in your efforts to remain competitive and win the bid.

We specialize in providing solutions for high-end applications and millworks, based on the requirements of our customers, meeting or exceeding their expectations and those of their clients by using the right materials and years of warp-free solution experience. Add to that, our commitment to you, to do everything in our power to support you in your efforts to remain competitive and win the bid.

If you are a millwork operation serving high-end clients, our 50 year guarantee for Sing products build both you and your customers’ high levels of confidence.

Services for Millworks

1. Oversize

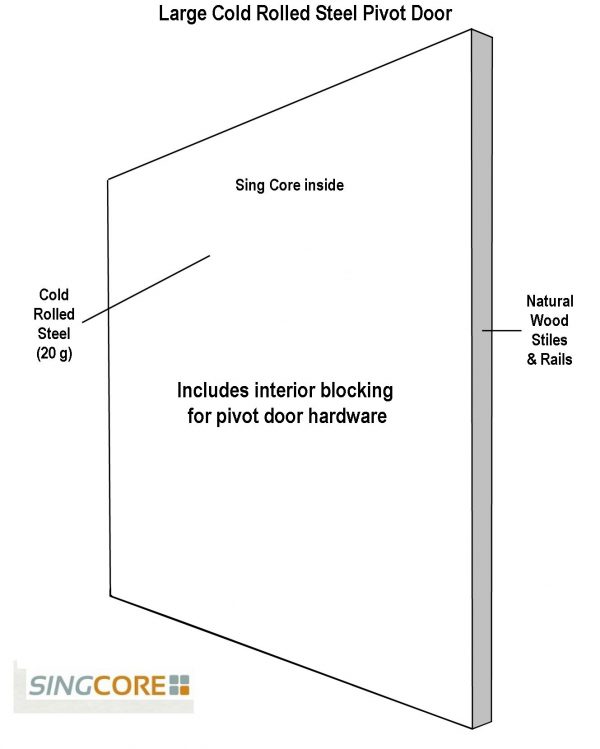

SingCore excels at creating warp-free oversize doors blanks or substrates in almost any exterior surface material; most popular is wood and/or aluminum up to 50 feet long in almost any thickness.

SingCore excels at creating warp-free oversize doors blanks or substrates in almost any exterior surface material; most popular is wood and/or aluminum up to 50 feet long in almost any thickness.

2. Production Work

We can custom manufacture to your specifications large quantities of door planks or panels in odd sizes for millworks used for doors, tabletops, room dividers, temporary walls, cabinetry, countertops, etc…

3. Custom Accommodations

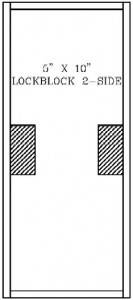

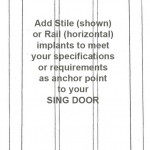

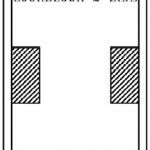

We can provide the customizations that you desire, like lock blocks, solid wood implants, anchor points for fastening, custom lite cut outs, a full range of skin and edging options.

Sing Core Team Guarantees:

| 1. On-Time DeliveryNew technology enables higher production at lower costs, perfect for large quantity orders in least amount of time and shipping is much quicker and easier than other methods. |

2. On BudgetOur simple pricing method makes it easy to track your bottom-line, plus our commitment to help you, “Win the Bid,” for large quantity orders and lower cost of shipping due to being so lightweight. |

3. Highest QualityWe only build the best door for the best clients in the world. High-end clients rely on us because we deliver only the best. Rest assured, your clients will be getting only the best doors backed by our 50 year guarantee. |

How is it possible?

| High Technology |

Best Price |

Best Doors |

Increased Capacity |

| SingCore uses the latest and most sophisticated, yet Eco-friendly technology to build the best doors in the world. Our specialty is the most challenging oversized doors for the most high-end clients in the world, with pride. |

SingCore door with our modern facility and new door building technology is 5 times more efficient than conventional door manufacturing. Fill out the simple price quote then you will see how together we can win the bid. |

SingCore doors are the only doors among the door industry that can be guaranteed warp-free for 50 years, lightweight, stronger than steel pound for pound, insulated, sound deadening, Eco-friendly, long-lasting and resistant to rot over time. |

Thanks to SingCore, you can bid on jobs that may have been considered previously to be too large for you. No reason to be intimidated by door jobs of more than 50 doors, as we can easily make 300-door-blanks-a-day for you. |

See: Door Specifications

Example Sing Solution

One of our most prestigious clients in the Mid-West needed 700 specific door blanks to fulfill an order. Rather than dedicate their resources to this order, they reached out to SingCore. We made the door blanks in three days, so the client was able to go on about their business as usual without having to bear the cost of adding staff, equipment and re-tooling.

Advantages:

Fast turnaround time – It took less than 3 days for SingCore to complete the order

High quality – Each door was manufactured with patented SignCore technology in Washington state, ensuring the end user guaranteed strongest true flat and lightweight doors. Note that the light weight of these doors saved more than half on shipping costs.

Easy to fabricate – Due to the patented SingCore process and our factory’s design and dedication to high quantity production, we are able to make more Eco-friendly doors in less time at less cost.

“…we were unable to compete for large quantity orders.”

Many of our partners report, “Before teaming up with SingCore, we were unable to compete for large quantity orders,” admitting that they simply stopped bidding on large quantity jobs (anything over 50 doors), because they knew they were no match for the major players; until SingCore.

Many of our partners report, “Before teaming up with SingCore, we were unable to compete for large quantity orders,” admitting that they simply stopped bidding on large quantity jobs (anything over 50 doors), because they knew they were no match for the major players; until SingCore.

SingCore routinely provides 200-to-300 doors blanks a day to distinguished door manufacturers, enabling them to compete even against companies that provide cheap import doors. With the majority of the work done in advance (Sing door blanks are easy to work with to build all types of sing doors) you can concentrate on finishing, adding hardware, delivering and installing the doors, knowing that they are receiving a superior product that guarantees satisfaction and longevity.

|

Sing Core |

Wood-based |

Foam |

Aluminum |

Balsawood |

Nomex |

Plastic |

Cardboard |

| Insulation |

✓ |

✓ |

x |

x |

x |

x |

x |

| Sound Deadening |

✓ |

✓ |

x |

x |

x |

x |

x |

| Lightweight |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

x |

| Strength |

✓ |

x |

✓ |

✓ |

✓ |

x |

x |

| Solid |

✓ |

✓ |

x |

✓ |

x |

x |

x |

| Eco-friendly |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Renewable |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Oversize |

✓ |

x |

x |

x |

x |

x |

x |

| Dimensionally Stable |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

| Affordable |

✓ |

x |

x |

x |

x |

x |

✓ |

| Waterproof Upgrade? |

✓ |

✓ |

✓ |

x |

✓ |

✓ |

x |

| Fire Retardant Upgrade? |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

✓ |

| Bullet-proof Upgrade |

✓ |

✓ |

x |

x |

x |

x |

x |

| Thickness Available |

✓ |

x |

x |

x |

x |

x |

x |

| Skin Options |

✓ |

x |

x |

x |

x |

x |

x |

| Easy to Machine |

✓ |

x |

x |

x |

x |

x |

x |

| Fast Turnaround |

✓ |

x |

x |

x |

x |

x |

x |