How Sing Core supports contemporary millworks and brings original architectural doors to life. Join top door producers in the country like Pella and Anderson Window and Doors to get on board with the SingCore revolution.

How Sing Core supports contemporary millworks and brings original architectural doors to life. Join top door producers in the country like Pella and Anderson Window and Doors to get on board with the SingCore revolution.

What we do:

“We are here to support you.”

50-year Sing Core Warp-free Solution

How to get a price quote:

Sing Core supplies valuable components to the construction process. Patented Sing panels, posts and beams are integrated into projects where the characteristics of lightweight, high strength, insulation and alternative Eco-friendly manufacturing options are either sought after or used in solving the problems associated with large scale projects.

The process works something, like this:

- The Architect specifies, “SingCore” inside the products, let’s say, a large pivot door

- The General Contractor seeks out a qualified Millwork who obtains unfinished pivot door from Sing Core

- Sing Core manufactures the pivot door blank to architectural specs and ships to millwork

- Millwork finishes and installs hardware and provides finished pivot door to the job site

- Installers hang and or install the pivot door

“Since we switched to Sing Core, we never have any warping issue, which was the biggest problem for recalls no matter how hard we tried to make our LVL cores work.”

Get Things Done Right the First Time

Millworks and door manufactures are rightfully wary about building and installing large or oversize wooden doors using traditional techniques. That’s why the top millworks in the country choose SingCore for challenging projects where they need to get things right the first time.

Guaranteed Warp-free for 50 Years

Here at SingCore we set the bar exceptionally high with a lengthy full structural guarantee that exceeds any other offered in the industry. This covers not only standard size door panels but oversize door panels exceeding 30′ in length.

Renowned for non-warping large doors, inventor Peter Sing’s patented and patent-pending building materials can do so much more. Patented SingCore is suitable for use in unsupported spans of almost any length with proper design support from our “True Flat” estimating team.

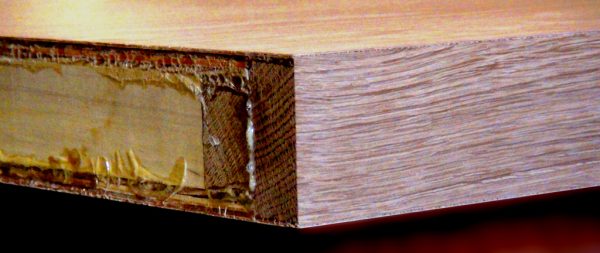

Strength of Sing Panel

Peter Sing’s miraculous material just boggles the mind, and is something that you have to get in your hands, or under your feet, to truly understand. Just look at this 13′ span, easily supporting the weight of a man without deflection at only 1″ thick. By including Sing Core in your next project, you may for the first time have complete confidence that your oversize door installation will stand the test of time, with no complaints from your clients.

The SingCore factory, located in the pristine forests of the Pacific Northwest, also builds posts and beams for use in other types of construction applications. They are just as lightweight and strong, if not stronger, than SingCore doors. Our specialty is devising a way to make your next project in to a success, no mater what it takes

Lightweight of Sing Panel

How Strong is Sing’s Core?

Independently tested, Sing’s core is 660 PSI, many times stronger when compared to any other lightweight honeycomb-type building material which usually clocks in at between 10 and 110 PSI.

That’s why you will find Sing Core inside impact doors. Sing says, “If you kick other doors, they will crash,

“Kick my door and you will break your leg.”

While lightweight and fully insulated, Sing Core is stronger that steel pound for pound.

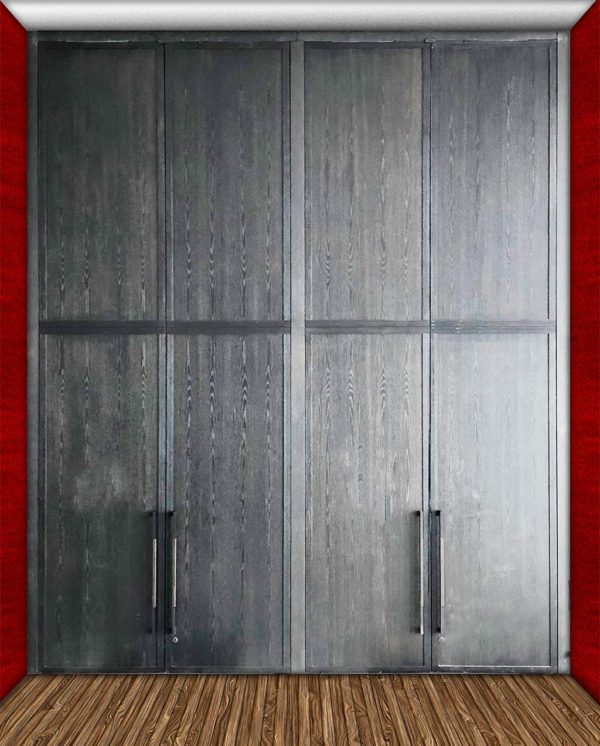

Finish to Match Any Style

SingCore offers a huge variety of skin materials, that allows you to achieve any design goal or match any existing element to perfection. Our specialty is in door panels, no necessarily door finishing, which is why we prefer to work with millworks on expensive projects. And, we often refer our clients to local millworks when possible.

- \

Surface lamination types include:

- Veneer, any species

- Wood stave, any species

- Metal – cold rolled steel, hot rolled steel, aluminum, copper, other

- HPL composites – Formica and Wilson Art

- Specialty such as white board, black board, magnetic marker board

- Veneer yourself (hot press ready)

- Paint grade panels

Every lamination is eligible to receive Peter Sing’s iron clad 50 year guarantee.

Architects are increasingly specifying their large high-end hot pressed veneer panelized walls, features, and doors have Sing Core inside (accounting for about one-third of all our products which are sent to the greater New York-area). The contractors generally contact Sing Core directly first, due to being specified. Though Sing Core does not actually do the veneering. Sing Core provides the high precision substrate that is shipped 3,000 miles from the manufacturing location in Washington State, to the high end millwork in New York (or wherever the nearest hot press specialist is near the construction site) to do the veneering there. We Do Not Veneer

We always recommend using your local veneering professionals for custom veneer doors. We do not provide veneer or install it. It is our policy to subcontract veneering jobs to the best veneering professionals in the USA.

If you offer hot-pressed veneer services or cold-press veneering to your clientele, your highest paying customers will gladly pay you more if your panels have Sing Core inside.

Hot-pressers Are More Successful and Profitable with Sing Core.

If you are a veneering professional, then we would like to work with you! Please contact us, we have plenty of veneering jobs to subcontract out.

For standard sized doors, we send our premium substrate to veneering professionals near the job site to be hot-pressed. If the doors are very large, we may have the veneering professionals prepare the veneer for us to cold-press in our facility.

For years, Sing Core has been providing high-end local and nationwide hot press veneer professionals with premium core material that eliminates the need for crossbanding.

Window Openings, French Doors, Man Doors, and Exotic Styles

Our perfectly straight true flat material is capable of fitting in to any form of door. Door openings are flexible and fully custom. Need a curved door? We can make you a custom curved door. Man doors? French Door? Other?

Any Size

Due to the incredible light weight of Sing Core and super strong resilience, the largest doors in the tallest buildings in the United States are built with Sing Core inside.

The last thing you want on the top floor of the World Trade Center, is a warped door, and that’s why you’ll find Sing Core inside those doors.

The last thing you want on the top floor of the World Trade Center, is a warped door, and that’s why you’ll find Sing Core inside those doors.

You could find Sing Core from beneath the depths of the sea (US Navy) to outer space (NASA) and everywhere in between.

Low VOA and Warp Free

Our friends at Crestmark Architectural Millwork found SingCore to be particularly useful in large cabinet doors for the Museum of Modern Art. Our warp free oversize panels combined perfectly with the museums need for low VOA materials for archival room use.

100-YEAR FURNITURE

SingCore has been used by the Seattle AIA for their flat back style office furniture. Unlike overseas competitors, who focus on quantity of quality, or furniture panels are designed and built to last a century or more. This makes sing core the go to companion for high end yet functional furniture installations. Coming it at 1/3rd the weight of all wood panels, SingCore is extremely popular in the modular or moveable furniture space.

A variety of travel industries are benefited by using Sing’s technologies, including, but not limited to hospitality, aircraft, aerospace, marine, rail, trucks, trailers, and RVs.

Most Sustainability of Any Other Building Material

Peter Sing’s gift to the world is this highly sustainable product which can virtually last forever with little or no deterioration, and can be repurposed on the fly, making it possibly the most sustainable building material in the world.

Can you afford to go without SingCore on your next project?