Home -> Products -> Sing Sandwich

| Education

How to Technical |

Media

Upgrades

|

Links

|

Pricing

|

2-2 Sing Sandwich

Professional Sing Sandwich |

|

AKA Sing Sandwich / Sing plywood / torsion box / super honeycomb panel

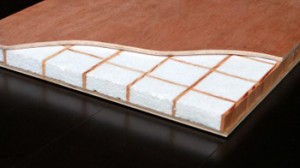

It is almost like sandwich from Deli but instead of bread on the top and bottom, the standard Sing Sandwich is made of 1/4 inch plywood sandwiching patented Sing Core in the middle.

Application of Sing Sandwich

Build your own Sing Panel by using Sing Sandwich

1 Use Sing Sandwich Core to build large Sing Panel or all sizes other than standard Sing Panel by adding solid edge (click “solid edge” to see option of solid edge of Sing Sandwich) on 4 sides or have pre-installed and option to add hard point for fastening in Custom Sing Panel.

2 Use as core to build any size and thickness Sing Panel.

Gallery – See also: What you can make with Sing sandwich panel as core or substrate to build endless Sing panel and post and beam.

Endless application of Sing Sandwich. Purchase Sing Sandwich panel from your local supplier and take it to your local millwork to custom-build your furniture, Sing doors and all types of lightweight, high strength products; even a tiny house or an entire home.

Endless application of Sing Sandwich. Purchase Sing Sandwich panel from your local supplier and take it to your local millwork to custom-build your furniture, Sing doors and all types of lightweight, high strength products; even a tiny house or an entire home.

You will be able to build the best long lasting products of lightweight, high strength Eco-friendly Sing Sandwich panel, not only for yourself but start your own manufacturing business by working with your local craftsmen. Better yet, you could start your own business making Sing products for resale because you are getting patented Sing Sandwich panels at a very low cost, and it doesn’t get any easier.

Sing Sandwich is the affordable insulated torsion box panel/sandwich panel/honeycomb panel that has the strength above almost any existing commonly used core click here to see comparasion of all types of core. Manufacturing Sing Core® uses less energy, no toxic chemicals or waste and is made in the USA. The heart and soul of Sing Sandwich is in our patented Sing Core structure; the strongest, lightweight, renewable core used in the aerospace, composite, boat, home building, furniture many other endless industry, compare commonly used core such as aluminum, plastic core, foam core, Nomax, balsa wood, paper core and other composite core materials.

See: What Can You Do with Sing Sandwich?

See also: Sing Sandwich Core in convenient 2 x 4 size

Sing Sandwich 4×8

48 in. x 96 in.

The Sing Sandwich 4×8 panel comes in standard 4 ft x 8 ft size panels, with 1/4″ plywood skin:

- 1.5 inch

Sing Sandwich features no solid wood edging, and may be edge-banded click here see solution of edge banding. to hide the visible exposed Sing Core material or add solid wood edge than cap with top and bottom skin to form Sing panel

See also: How to Close the Edge of Sing Sandwich

2 ft. x 4 ft. size

See also: Sing Sandwich Core and Professional Sing Sandwich are available in convenient 2 x 4 size and may be purchased as a sample with free shipping.

Applications of Sing Sandwich Panels

There are so many things that you can create with your Sing Sandwich, knowing that by doing so, your end product will be manufactured with a True Green Eco-friendly material that is lightweight, stronger than steel pound for pound with built-in insulation. Click here to see hundreds of products that could be made of Sing Sandwich.

The Sing Sandwich is constructed using the most responsible use of natural wood from nature to build the 2 inch x 3 inch torsion boxes, recycled rigid foam and expensive urethane glue that is formaldehyde-free and water resistant. each Sing Sandwich is manufactured using manual labor and low energy equipment in the USA with little or no waste.

Click here to see photos of Sing products made of Sing Sandwich

Following are examples of some applications that have used Sing Sandwich:

Make the Best Butcher Block

Make the best butcher block and much more, Sing Sandwich is much lighter in weight than solid wood but creates high strength Eco-friendly products such as floor, wall, roof, table top, furniture trade show display, etc… with all the beauty of wood but without the warp, twist, cup or other problems associated with solid wood and can be used just like you would any lightweight plywood.

Some of the best high-end furniture features butcher block, which is an elegant display of the natural beauty of wood grains. You see butcher block featured in everything from doors and countertops to furniture, like cutting boards, kitchen islands, tables, workbenches and large conference tables. The problem is, that butcher block tends to bend and twist thus compromizing the structural integrity of the project.

That’s where Sing Sandwich comes in to rescue the day. For years, using Sing Sandwich as substrate has been the high end millowork’s secret weapon for making non-warping butcherblock surfaces that stand the test of time.

Create Hardwood Lumber On Demand

By having a quantity of Sing Sandwich panels on hand, you can create your own hardwood lumber, posts and beams, furniture parts, metal composite building materials at your location, when you want it, as you need it! Having a Sing Sandwich panel inventory is the secret weapon in exclusive high-end millworks.

Create any size panel you want

Due to its extreme versatility, Sing Sandwich panels can be ripped and cut just like any other plywood-type building material. Cut into strips and glue together to make your own posts and beams, then finish them in any exterior material that meets the specifications of your project.

Want large panels?

Certainly, when we build large panels, we can certify and guarantee them as true flat, using our seamless technology. But, you can manufacture your own oversized panels by patching as many Sing Sandwich panels as you need to achieve the desired dimensions of your project at your location.

Want an even better deal?

Special truckload price inquiries will also receive an extra discount for quantity. Contact us to take advantage of our special-priced offer.

Sing Sandwich in its original form is perfect for use as:

Shelving, low cost lightweight table, table legs, furniture parts, floors, walls, ceilings, trade show displays, sign board, sound barrier, etc…

A 4 ft x 8 ft x 1.5 inch Sing Sandwich panel with plywood skin weighs approximately 55 lbs. 55 pounds is a fraction of the weight of the equivalent piece of plywood… and heavy plywood can be dangerous to maneuver and/or requires extra equipment to accommodate. Even so, plywood could not be true flat or super strong like the equivalent Sing Sandwich panel.

That is why the Sing Sandwich panel is perfect for:

- Shelf

- Cut to any width for lightweight strong shelf, long span capacity.

- Substrate

- Insulated, true flat, lightweight, super strong for door core, table core.

- Slice to any thickness.

- Furniture components

- lightweight , strong and long lasting non warp high quality furniture.

- Tiny house

- For wall structure, floor substrate, room loft floor.

- You may use one inch thick plywood to build your tiny house but it will not as straight as Sing core, it will be more than double the weight of Sing Sandwich panel

- One inch thick plywood will have only about half of the strenght of sing sandwich

- It cost more to ship heavy plywood and cost more than Sing Sandwich panel with same grade of quality.

- Countertop

- substrate could be finished in any exterior material

- Ceiling

- Lightweight ceiling.

- Hurricane

- window and door protection cover.

- Use Sing Sandwich

- as core or substrate material to build Sing panel and

- other endless applications.

Want to order by the truckload? Contact us for wholesale price.

Applications of Sing Sandwich Panels:

See Also: Sing Panels

How to purchase Sing Sandwich panel?

To buy Sing Sandwich, please contact our sales team.

The only way to purchase Sing Sandwich panel is purchase our standard sizes of either 2 ft. x 4 ft. or 4 ft. x 8 ft. in inch-and-a-half thickness.

We also provide Sing Panels in almost any size such as 12 ft wide x 50 ft in length, up to 6 inch in thickness. Wholesale inquiries click here. All you need to tell us is the length, width, thickness, and type of skin you want.

Here at Sing Core, we make the world’s best Eco-friendly oversize doors that are lightweight, stronger than any other comparable material, and are true flat. No one else could accomplish this feat if not for the Sing Core composite secret ingredient.

Now you can have the convenience of Sing Sandwich panels – that are superior when compared to other materials – in stock at your location at huge savings due to this one-time offer. See Sing Sandwich Photo Gallery to see other varieties of options available and can be made to your specifications.

Standard sizes, thicknesses, faces and quantities are limited to those listed. For other dimensions and/or options please complete our online price quote for a price.

Standard sizes, thicknesses, faces and quantities are limited to those listed. For other dimensions and/or options please complete our online price quote for a price.

Standard Sing Sandwich Panel Details:

- dimension: 2 ft x 4 ft (in pairs only)

- thickness: 1 ½ inch

- standard 1/4 inch plywood surface

Sing Sandwich panels are so versatile, they have hundreds of applications. You could use these patented sandwich panels to build your own lumber, or

Construct a tiny house

Construct a tiny house- World’s smallest house

- Make a door

- Use as flooring

- Ceilings

- Stair treads

- Trade show displays

- Store fixtures

- Signs

- Transportation applications

- Cold storage

- Tables

- Furniture

- … and so much more …

Sing Sandwich Comparisons Based on 2″ x 2″ Grids

| Sandwich Panel | Foam | Aluminum | Balsawood | Nomex | Plastic | Cardboard | |

| Insulation | ✓ | ✓ | x | x | x | x | x |

| Sound Deadening | ✓ | ✓ | x | x | x | x | x |

| Lightweight | ✓ | ✓ | ✓ | ✓ | ✓ | x | x |

| Strength | ✓ | x | ✓ | ✓ | ✓ | x | x |

| Solid | ✓ | ✓ | x | ✓ | x | x | x |

| Eco-friendly | ✓ | x | x | ✓ | x | x | ✓ |

| Renewable | ✓ | x | x | ✓ | x | x | ✓ |

| Oversize | ✓ | x | x | x | x | x | x |

| Dimensionally Stable | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Affordable | ✓ | x | x | x | x | x | ✓ |

| Waterproof Upgrade? | ✓ | ✓ | ✓ | x | ✓ | ✓ | x |

| Fire Retardant Upgrade? | ✓ | ✓ | ✓ | ✓ | ✓ | x | ✓ |

| Bullet-proof Upgrade | ✓ | ✓ | x | x | x | x | x |

| Thickness Available | ✓ | x | x | x | x | x | x |

| Skin Options | ✓ | x | x | x | x | x | x |

| Easy to Machine | ✓ | x | x | x | x | x | x |

| Fast Turnaround | ✓ | x | x | x | x | x | x |

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

Strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

Affordable: Even though Sing Core technology is used in high-end applications, we make it affordable for broad use in a large number of applications. Sing Core performance is comparable to any high-end core but could be as little cost as low-end wood product core.

Waterproof upgrade: Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements.

Fire retardant upgrade: When used in fire retardant applications, the Sing Core fire retardant door is the lightweight, super-strong, eco-friendly alternative.

Bullet-proof upgrade: In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core.

Thickness available: Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: For many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc… see Sing Panel

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Sing Panel Skin Option Examples:

Sing Panel Skin Option Examples:

… just to name a few, (skin options available in Sing Panel configuration as the possibilities are limited only to any available flat building material).

SAMPLES AND TRIAL SIZES:

This is Sing Sandwich

- Exposed insulated inner structure

This is What You Can Do with Sing Sandwich

- Sing Core bookshelf

- Sing Core bookshelf

- Insulated Storage Unit

- Panelized Tiny House