Architectural Door Definition

An architectural door is one that is designed by an architect with a particular form, function, and aesthetic feel to it that might appear as though it were solid wood, metal, stone, opaque glass, or other natural or manmade material. An architectural door consists of an architectural panel designed and finished according to the architectural specifications, articulating with hardware to provide access or hide and reveal specific features or locations in or around a structure for a distinct application.

Advanced technologies offer nearly unlimited opportunities for architects to let their creative abilities to flourish in the architectural door arena, as projects that were restricted by the limitations of certain building materials can now be overcome by composite and hybrid technologies.

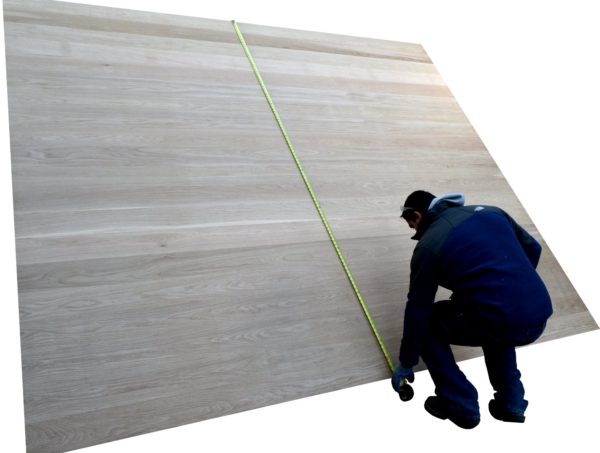

Now, door architectural doors can be made of nearly any material or in any size without having to compromise the architectural door’s integrity. Architectural doors can be made to be lighter in weight, much stronger, with higher precision, insulated, and guaranteed not to warp, twist, cup, or otherwise fail (including structure and lamination) for up to 50 years.

Architects are no longer limited by archaic rules and limitations, thanks to new and emerging technologies such as patented Sing Core substrate which empowers door designers to imagine and create doors of magnificent proportions without having to account for weighty or flexible building materials.

Architectural doors can cow feature the following raw materials:

Non-rigid Architectural Door Materials

When creating an architectural door, there is a tendency to use materials which are not customarily used in various combinations in a large oversized front door design. The larger the door the less rigidity these materials may have.

Natural Wood

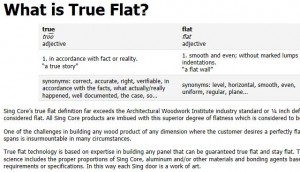

Natural wood is the most problematic substance to include in any large modern architectural design due to its tendency to move in accordance with environmental changes. Thanks to inventor Peter Sing’s patented Sing Core and patent-pending anti-warp technologies, his True Flat Team can assist in creating the prefect warp-free substrate which can be engineered to counteract almost any surface materials propensity to move, keeping the architectural door straight and true regardless of size.

Heavy Architectural Door Materials

Building an oversized architectural door using heavy materials such as concrete, steel, lead, stone, brick and mortar, and the like can be hugely challenging due to the excessive weight. The bigger the door, the more weight, stress and strain on the structure when operating such a monumental architectural door.

Again, Sing’s invention provides a high-precision lightweight substrate which can unfailingly support the weight of heavy architectural materials, and support the materials exceedingly well, while remaining lighter in weight, and can also be guaranteed not to fail for 50 years.

How Is It Possible?

You might ask yourself how this new patented technology can make the previously impossible large architectural door designs possible in present day? Sing’s patent holds the answer.

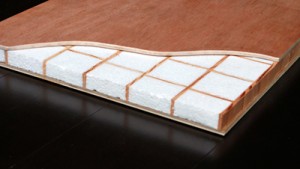

Peter Sing’s revolutionary patent is based on a hybrid combination of old and new technologies to create a lightweight architectural composite substrate that is stronger than steel pound-for-pound.

He starts with a torsion box grid structure using vertical grain natural wood fiber to form small grids two to three inches, then fills the otherwise empty structure cells with rigid foam material and sandwiches the metric structure between two sheet goods to complete the reinforced structural insulated hybrid panel.

This is the revolutionary core technology that has revolutionized the architectural door market across the board.

That’s why more and more architects are specifying Sing Core Doors in their most prestigious contemporary architectural design projects.