The pocket door has been one of the more interesting types of doors that is not only functional but clever in its ability be secluded out of sight, like a hidden door or room divider. Pocket doors are doors that slide into the wall. Also referred to as a cavity sliding door, a sliding cavity door is just like what it’s called, as the door is hidden inside a cavity inside the wall when in its opened position.

As the best architects, millworks and door manufacturers realize that while these types of doors are an effective and brilliant combination of brilliance and creativity, the pocket door does present a few problems associated with their use. That’s why you want to use the best pocket door system.

The Top 7 Problems with Pocket Doors Solved

1. Pocket Doors Warp – Problem

Let’s admit it; the number one problem associated with pocket doors is door warping. A warped sliding pocket door is a huge problem because there is usually a nominal amount of space on either side of the door when the door is snuggled inside the sliding door cavity. A little warp will damage the finish of the door, while a more severely warped pocket door will cause the door to get lodged within the wall, making it difficult to pull out without causing other complications or damage.

1. Pocket Doors Warp – Solution

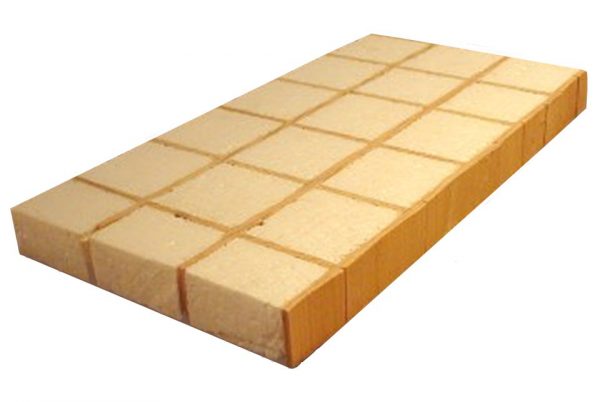

Sing Core provides the best pocket door manufactures with the only lightweight warp-free pocket door core which is based on a combination of patented reinforced insulated vertical grain torsion box core and composite anti-warp stiffening inserts (patent pending) to provide the only warp-free solution regardless of building materials used (even solid wood stave).

2. Pocket Door Weight – Problem

As a rule pocket doors are pretty heavy, and they’re made to be heavier, because unless you know better, you think that the thicker the door is the less it will tend to move, which is the bane of all wood pocket doors. In the case of pocket doors, adding weight is not the answer, unless you’re in the pocket door maintenance and repair niche.

2. Pocket Door Weight – Solution

The Sing Core lightweight pocket door solution revolves around the lightest weight Eco-friendly pivot door core weighing-in at a fraction of the weight of other wood-based solid wood core. Superior lightweight performance without compromising strength, precision or performance.

3. Pocket Door Repair – Problem

When you have problems with your pocket door it’s going to be a costly issue when dealing with pocket door repair. Why? Unlike other fixed doors which are exposed your pocket sliding door is generally not seen in its opened position, making access to the door unlikely without having to remove the wall supplying the door’s cavity.

If you have to pay for pocket door repair, keep in mind, it may be costly and it will cost you many times the cost of your door over time, especially if it is a wooden door because it will be even more susceptible to warp. While repairing a door can be costly, it might save you money by considering pocket door replacement every so often.

3. Pocket Door Repair – Solution

Sing Core is unprecedented in its reparability. For instance, you could skewer your pocket completely through with fork lift forks and repair it on site by cutting out the damaged area with a chainsaw, glue in a new piece of Sing Core, putty, sand and finish the pocket door and it’s just like new. No compromising the strength or integrity of the original Sing Core pocket door, without even dismantling the door.

4. Pocket Door Hardware – Problem

Pocket door maintenance will include maintaining the hardware, and if your door is a heavy one. The more you use it, the more maintenance will be necessary over time. Plus heavy pocket doors can also compromise the pocket door frame as well as the structure due to stress and strain of operating your door over time. Heavy pocket doors require expensive heavy duty hardware for heavy doors because the pocket door hardware is based on the pocket door’s weight.

4. Pocket Door Hardware – Solution

Since the Sing Core composite pocket door core solution is so lightweight, you can save so much money on being able to use lightweight pocket door hardware (since pocket door hardware is based on weight), not to mention the savings in transporting, handling, manpower and equipment necessary to install the completed pocket door system.

5. Pocket Door Precision – Problem

The problem with pocket doors is that it is difficult to make them with any degree of precision, due to the limitation of the building materials and manufacturing process. Natural wood moves, so it could be straight and true upon installation, but not long after. If welding is used in the manufacturing process, this may also cost you your pocket door’s precision. A single pocket door may not require high precision if it is the only door in the cavity, but what if there are other doors sharing the same space, precision is of primary importance.

5. Pocket Door Precision – Solution

No other Eco-friendly, lightweight high-strength pocket door core can compare to Sing Core in terms of high precision. With the highest tolerances (+/- .006 in.) patented Sing Core can be sanded, milled or machined so precisely, that’s why you see Sing Core everywhere from beneath the ocean (U.S. Navy) to outer space (NASA) and everywhere in between when high precision and dimensional stability are the most important factors.

6. Double Pocket Door – Problem

The highest precision is necessary to accommodate more than one pocket door in the wall’s cavity which is an invitation for constant maintenance, as multiple pocket doors (2 or more) are rubbing up against themselves due to lack of precision or warp gone wild.

6. Double Pocket Door – Solution

Sharing the same pocket door cavity with not just double pocket doors, but multiple doors, is no problem for patented Sing Core. No pocket door core material is as lightweight, Eco-friendly or high precision. You can stack many doors side by side inside your wall cavity packed very tightly with very little wiggle room, and you, your architect, millwork or pocket door manufacturer won’t have to worry about your doors staying straight and true.

7. Large Pocket Doors – Problem

The bigger the pocket door, the bigger the problems. Large pocket doors are the most problematic because they are big, they are heavy, and if they’re over 7 ft. tall and/or 3.5 ft. wide they will be heavier, meaning more expensive hardware that could be many times the cost of the door, increased maintenance due to even more stress on the pocket door frame as well as the structure. What about the warping? Large pocket doors are just asking for trouble, because building one out of standard building materials is a little better than building it out of fresh spaghetti.

7. Large Pocket Doors – Solution

The bigger they are the brighter Sing Core shines through. You can build a 34 ft. tall large pocket door that weighs about 10 percent of its solid predecessor and will not warp, bend, twist of otherwise fail. Your large pocket door can be made of any flat building material in any size and can be guaranteed for 10 full years of faithful service. That’s why the biggest door manufacturers in the world use nothing but Sing Core in their large oversized doors.