$1 billion to help the homeless by Inslee. Our new invention will help to make this project successful.

|

This can be a pilot project to extend to the rest of the country and even to the rest of the world due to the uniqueness, structural qualities, low cost, and higher quality than standard solid wood studs….click to see the solid wood studs used as shipping container exterior insulation structure which is more than double the cost of material and labor than our new invention by using hollow 2 x 6 studs.

|

The advantages by using our newly invented Sing hollow 2 x 6 studs are list below.

1. More insulation less cost; use of blow in insulation material will cost far less material and labor to insulate the entire roof and wall, even floor with two people less than a couple of hours to reach R-40 roof and R-20 wall required by energy code.

2. Easy to construct on the site or prefab at factory site to penalize a house with window and door in the prefab panel and assemble the entire wall and roof on the job site, It will save the construction labor and time due to lightweight high strength. compare with conventional solid 2 x 6 frame home building methods which require drilling for wiring and plumbing.

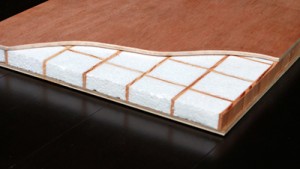

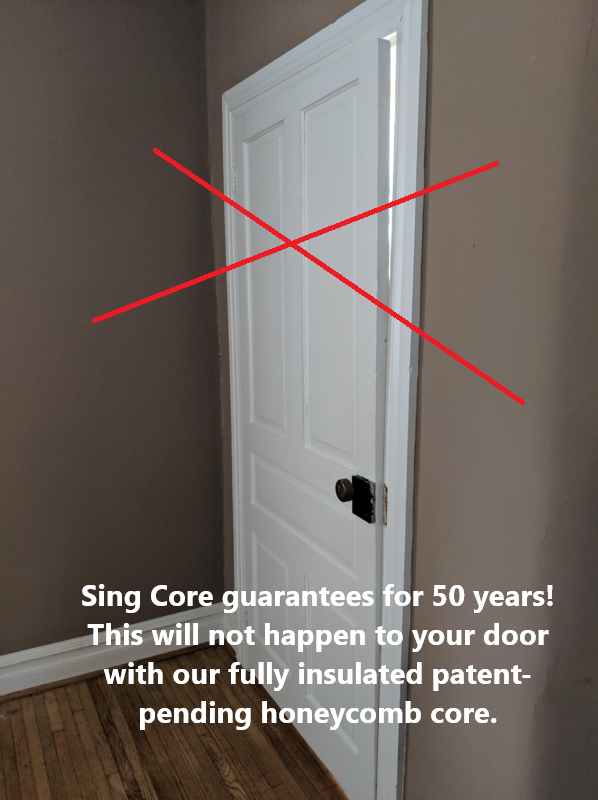

3. Environmental friendly; Sing studs use less than 1/3 of wood fiber but stronger and homogenous vertical wood veneer dimensionally stable straight fiber which takes only 5 % of the wood waste rather than conventional saw lumber practice which has far more water to create conventional 2 x 6 solid wood lumber which is easy to warp due to high water contents and wood fiber unevenly distribute of solid wood studs.(It takes far less energy to dry thin wood veneer which is the only material used to make the structure of Sing studs than solid 2 x 6 wood lumber).stronger dryer Sing studs will have less chance to warp and cause mildew.

Others have attempted to solve this, but still using standard studs.

Others insulate containers with standard 2″x6″ solid studs. The material costs more and will take a lot of time to build compared to Sing Studs.

See what others have done:

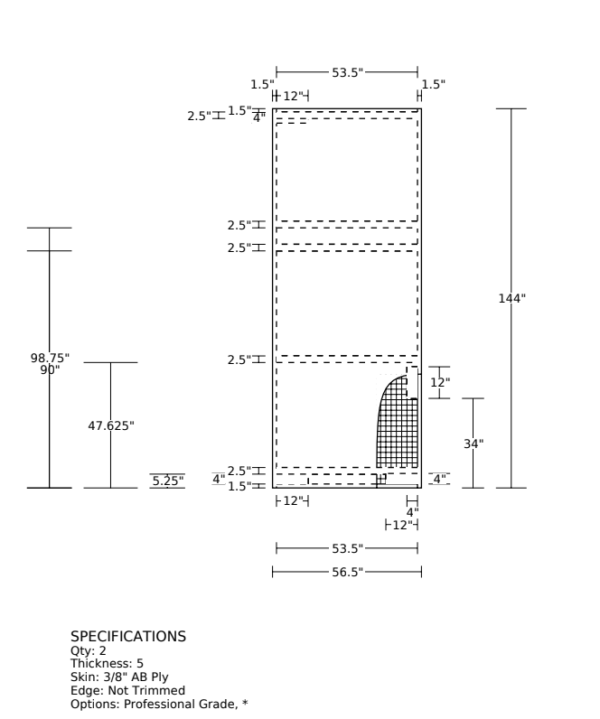

The metal only costs $2200, but you still need to purchase the studs themselves. Total is 120 pieces for our prototype project. Perfectly straight, made of vertical grain LVL and solid wood connecting to each other. Exterior frame insulation for container. The reason for Sing Studs being cheaper is that they produce less waste than conventional studs, it is easier to build, and it uses homogenous wood fiber. Dry kiln LVL has 6-8% moisture content while studs have a whopping 18% moisture, which means the conventional studs have more tendency to move over time. Stud waste is about 30%, while LVL waste is only about 5%. Our unit can be easily dismantled and re-located.

|

|

|

|

|

|

It will take much more time and money to use the metal bracket and solid 2″x6″ studs as shipping container insulation methods which costs more than $2,195.00 just for the metal bracket to connect 2″x6″ solid studs to cover the shipping container. On the other hand, Sing studs cost less than half of the price and includes all the studs and hardware. Sing Studs container insulation method is very easy to install and fill with blow-in insulation materials. It only takes less than 3 hours to complete a 40 ft. container.