Here at Sing Core, we are contacted regularly by the most particular clients who seek only the best lightweight, high-strength portable floors made to the exacting architectural specifications. By using Sing Core to build a portable floor, even a low-priced (built with standard sing Sandwich panels) do-it-yourself raised floor you will be miles ahead of other modular floor systems. Just because you’re using our reinforced torsion box composite building material your resulting portable floor will be lighter in weight, stronger, insulated, sound deadening and does not require a complicated infrastructure to accomplish the results that you desire. No other company can make floors like these. No other system allows you to use less joists than our system. This results in a dead load that is so light it’s unmatched by any other system.

Here at Sing Core, we are contacted regularly by the most particular clients who seek only the best lightweight, high-strength portable floors made to the exacting architectural specifications. By using Sing Core to build a portable floor, even a low-priced (built with standard sing Sandwich panels) do-it-yourself raised floor you will be miles ahead of other modular floor systems. Just because you’re using our reinforced torsion box composite building material your resulting portable floor will be lighter in weight, stronger, insulated, sound deadening and does not require a complicated infrastructure to accomplish the results that you desire. No other company can make floors like these. No other system allows you to use less joists than our system. This results in a dead load that is so light it’s unmatched by any other system.

Portable Modular Stage Floor Example

View the following video of assembly of this 20 ft. x 12 ft. portable stage that could be used as a dance floor, raised floor, temporary flooring. Imagine being able to load up all the modular components and layout your temporary flooring in convenient sections (as you can see each component can easily be carried by one person) and snap it all together in 12 minutes?

This 12 minute insulated portable stage assembly has been time lapsed to a brief 1 minute video.

The Sing Portable Stage

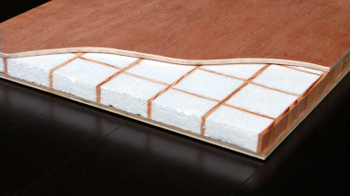

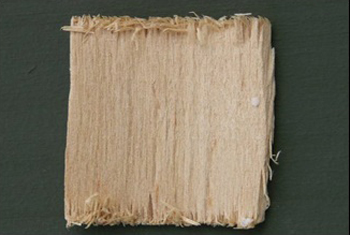

When you’re making a portable stage out of patented Sing Core, you are using the most advanced floor materials in your portable stages. Think about it; what other Eco-friendly building material can offer such lightweight, high strength and insulation?

When you’re making a portable stage out of patented Sing Core, you are using the most advanced floor materials in your portable stages. Think about it; what other Eco-friendly building material can offer such lightweight, high strength and insulation?

Why insulation? Just ask our Sing Core clientele. Architects, designers and sound engineers seek us out for the sound deadening qualities that come with the nature of the patented Sing Core substrate that is basically a wood torsion box structure / rigid foam composite that is a noticeable improvement when measured against other traditionally available stage platforms.

The sound deadening qualities of sing Core can enable a live band with an acoustic drum kit (or DJ) to perform upstairs overhead of a restaurant without impeding the quality of dining going on below. What would you do with your Sing Portable Stage?

Huge floor panels that are light enough to lift with a finger

DIY Dance Floor

If you engage in periodic dance events requiring a dance floor rental, it wouldn’t take long to pay for your own Sing portable dance floor. Sing dance floors can be built to your architectural specifications in easy to use modular sections that are custom designed. Why not build your own portable dance floors?

The avid do-it-yourself could easily create his or her own portable dance floor system using Sing Sandwich panels available via your local Lowe’s Pro Desk. Sing Sandwich panels are available in 4 ft. x 8 ft. standard size, or pre-cut into convenient 2 ft. x 4 ft. modular dance floor sections to create your own portable DIY dance floor.

Sing portable dance floors can be used inside or out. Custom built to your specifications, you can have the best outdoor dance floor that can be assembled and disassembled at will, or left outdoors for extended periods of time without compromising the structure or integrity of the portable floor systems.

Industrial Floor

Sing modular floor systems are being used every day for the most intricate industrial floors in factories, in marine and aerospace temporary floors and as their preferred raised floor system.

See Also: Sing Floors, Wide Plank Flooring, Large Floor Panels, Ice Hockey Flooring and Stage and Event Flooring