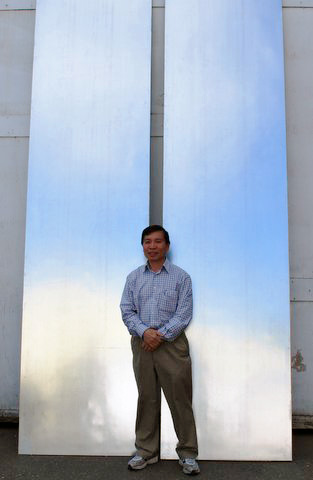

Sing Core Cold Rolled Steel Panels are as strong or stronger than solid steel panels yet so lightweight that one man can easily carry a 4 x 8 panel with his bare hands.

These SingCore 20 Guage Cold Rolled Steel Composite Panels measure 35″ x 13′ x 1″ are lightweight.

These SingCore 20 Guage Cold Rolled Steel Composite Panels measure 35″ x 13′ x 1″ are lightweight.

These panels have been used in material handling, conveyor troughs, metal floors, lightweight steel decks, lightweight truck decks, portable steel walls, factory sliding doors and magnetic steel boards.

Though the application are numerous and nearly unlimited, you will find Sing Core cold rolled steel panels are popularly used in applications such as aerospace, alarm systems, audio equipment, control rooms, electronic games, equipment enclosures, fire alarms, inspection rooms, laboratories, laser rooms, manufacturing cells, medical libraries, mezzanines, microelectronics manufacturing, nano technology, observation decks, operator booths, paint finishing enclosures, powder coating enclosures, security control booths, security systems, shipping area offices, telecommunications, warehouse systems and work platforms, just to name a few.

Sing Core Cold Rolled Steel Composite Panels are made lightweight, yet so extremely strong due to our patented sing core technology that is unparalleled in the industry. Nothing is stronger or so lightweight as Sing Core.

These Cold Rolled Steel panels were custom-ordered, and have been used to make lightweight steel honeycomb doors, decks and walls. We specialize in going the extra mile to get you the product that your design requires, and are not limited by normal dimensional restrictions. We can make any lightweight cold rolled steel panel to your specifications, in any length, any width and any thickness.

Compared with stainless steel plate, stainless steel composite offers increased formability and lighter weight and facilitating installation and handling. Due to the extreme toughness of stainless steel, special fabrication guidelines need to be taken into consideration.

Steel sounds heavy already as we hear the word, but ways to make it lighter are now available. It is not a modification of the material as such but the smart hybridizing of steel with a lightweight honeycomb structure that makes “steel” less massive.

Sing Core Cold Rolled Steel panels consist of two cold rolled stainless steel face sheets enclosing the patented sing core. This innovative core material structurally produces an extremely lightweight panel sporting a true flat surface that excells in both heat and sound reductive properties. Practical applications include decoration of elevators, yachts, exterior an dinterior walls of buildings.

Steel is one of the most common engineering materials in the world. It is a fundamental resource used in a variety of industries for constructing buildings, infrastructure, tools, ships, automobiles, machines, appliances or weapons. It is known for centuries as an incredibly strong and tough construction material.

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features.

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features.

Sing Core Cold Rolled Steel Panels have a wide range of applications, are not limited in length or width and though we excel in large projects, we also provide solutions for reduced dimesions for smaller projects.

The example to the left is an application that was used in material handling. This trough is constructed with 20 gauge cold rolled steel and is used for moving raw material.

The image to the right is an example of a cut out that was made in the trough.

These are just a few examples of how Sing Core Cold Rolled Steel Panels are flexible and easy to use in a variety of applications.

Sing Core Cold Rolled Steel Panels are incredibly lightweight and strong.

Sing Core Cold Rolled Steel Panels are incredibly lightweight and strong.

The photo (above and right) shows just how lightweight this magnetic sign board is even though it was manufactured using 26 guage cold rolled steel.

Advantages of Sing Core Lightweight Cold Rolled Steel Panels Include

- Low structural weight fraction

- High stiffness / panel stability / flutter resistance

- Robust designs (carries loads after high impact)

- Simplified construction (reduced fasteners / part count) equals lower assembly cost

- Impact damage easily detected and repaired

- Eliminates corrosion issues of aluminum

- Fluid intrusion / leakage can be eliminated

- Broad design latitude (few restrictions)

- High temperature capability

High stiffness, low weight, good thermal insulation, magnetic properties as well as smooth surface (coloured if needed) make Sing Core Cold Rolled Steel Panels your primary solution for use in many applications, including panels for visual communication, solar energy, elevators, rolling stock, automotive and trucks, ship building and many others.

Sing Core Cold Rolled Steel panel patented technology is an excellent match for your mass production process while maintaining a sustainable environment where production costs can be kept low by use of the our patented “true green” production process.

Our Guarantee

When you buy our professional panels, you get our Signature 50 Year Warp Free Guarantee. It ensures you decades of worry free performance. Sing Core Panels are 100% made in America. Every panel is handmade, so you get the best quality possible.

When you buy our professional panels, you get our Signature 50 Year Warp Free Guarantee. It ensures you decades of worry free performance. Sing Core Panels are 100% made in America. Every panel is handmade, so you get the best quality possible.

We also use materials that are sourced from North America, which means you get better quality products made from better materials. Coupled with our patented and patented pending Singtech engineering, you get the best of everything!