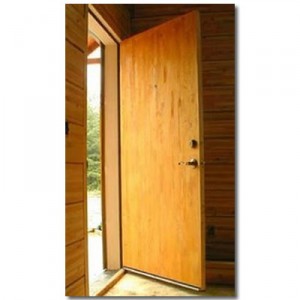

The Strongest Core Makes the Strongest Door

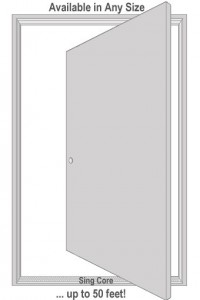

Our panels have the extreme strength to support large amounts of weight with little to no flex.

Sing Core has become known for our ability to produce panels that are exceptionally strong, yet light weight, warp-free, and more versatile than any other panel on the market.

Our panels have the extreme strength to support large amounts of weight with little to no flex. There is no other door we know of that allows you to support multiple people without compromising the structure of the door.

The secret ingredient in any Sing Core product is the extreme strength of the core material. Peter Sing created the formula for the strongest and the straightest door core material which allows you to make panels that are super strong, super light weight, super, straight, visually appealing, and allows you to apply almost any skin, because the substrate is so structurally stable.

Outperforming the competition

No other lightweight building material compares to patented and patent pending Sing Core.

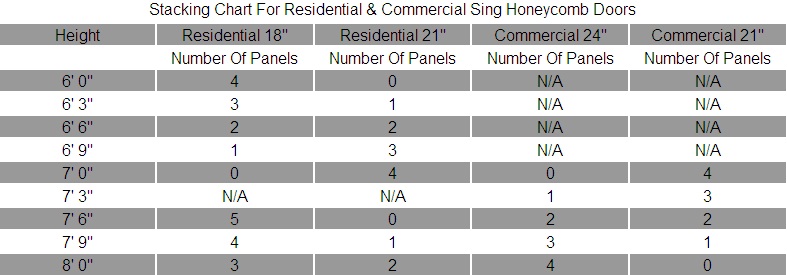

The core is a comprised of natural wood grain fiber arranged in a honeycomb pattern tightly supported by eco-friendly, recyclable EPS foam, sandwiched between to skins consisting of nearly any building material completing the torsion box design.

We have extensively tested doors made with Singtech against competing doors. The results were clear that our doors are able to withstand far more pressure compared to doors made by the competition.

This creates a structurally sound material that has superior strength. Sing Core has been independently studied at Washington State University and concluded to be stronger than steel in strength tests.

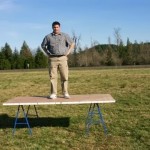

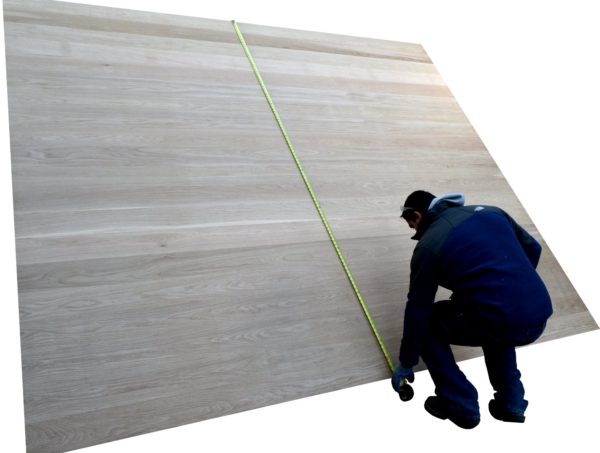

This grown man can actually stand in the middle of this 12 foot span with merely one support on each side. As you can see, there is practically zero flex on the panel with the weight of a full grown man.

This short video demonstrates the extreme strength and lightweight attributes of our eco-friendly, sustainable material.

It is an example of a lightweight, nearly indestructible, modular collapsible table, featuring a guest appearance by Inventor, Peter Sing, and also includes a short furniture demonstration.

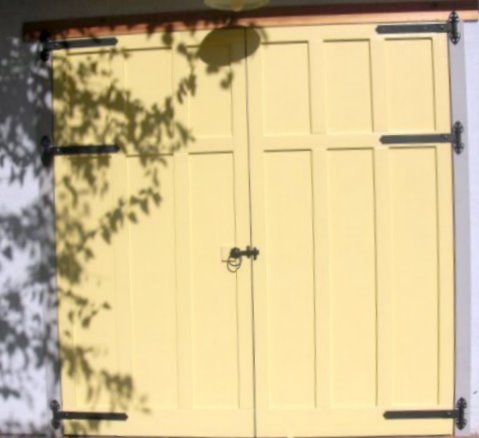

The Patented Sing Core material can host any exterior surface, like (but not limited to) concrete, ceramic, fiberglass, aluminum, stainless steel, fire-resistant Magnesium Oxide (MgO) Board, bullet-proof Kevlar, etc.

Sing Core is your only choice when it comes to substrate that is strong, light in weight, warp free, offers sound deadening capability, and guaranteed warp free for 50 years. No other panel can do this!

Hammer Strength

Independently tested to be able to withstand force of up to 660 PSI, our panels are vying for the absolute top spot among the strongest of the strongest panels on the market.

When using a hammer on our doors to test them, you will see how strong they sound. Try it for yourself.

“Like solid steel.”

Peter Sing, Founder, Owner

Note: hitting our doors with hammers may void your guarantee.

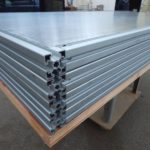

Our Panels are Hand Made and Guaranteed

In this day of outsourcing and importing, very few products in America are truly hand made anymore. American products are well known for their exceptional quality and precision. Sing Core products are the pinnacle of that philosophy, bringing you top of the line panels that are 100% handmade in the USA, using materials that are nearly 100% sourced from America.

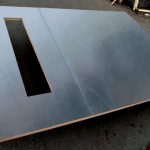

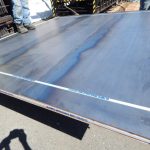

- Deflection test of a finished high pressure laminate trailer deck.

- Lightweight Strong Tables