Whether your specifications are for commercial or residential, Sing Core’s architectural panels are technologically advanced building materials offering superior performance in every category when compared to traditional metals, wood, and other composite products, offering a superior alternative to traditional room partitions.

Case Study Comparison:

| Traditional Partition Wall Panel |

Sing Core Partition Wall Panel |

| Height: 25 ft |

Height: 25 ft |

1100 lbs

|

198 lbs

|

Just in the weight, alone, Sing Core leads the pack. While it may take a team of installers and heavy equipment operators to install traditional partition wall panels, Sing Core panels can be installed quickly and easily due to being so lightweight (which also means fewer on=the-job injuries)for considerably lower installation costs. That is only in the area of overall weight reduction, which also means less expensive hardware, less strain on hardware and structure, less maintenance. Beyond the issue of weight, Sing Core partition walls also have these characteristics: Eco-friendly, Superior strength, Insulated, Sound deadening, Longer lasting (50 year guarantee), Warp-twist-crack-resistant, and more importantly costs much less than you are paying now (possibly less than one-third the cost).

Note: this comparison is based on 3.5 inch thickness, even though Sing Core can achieve the same strength (or greater strength) in comparison at 1/3 the thickness of other material.

OFFICE PARTITIONS

Sing Core office partitions are custom designed and manufactured to fit your space, the look and feel of the existing structure while maintaining the integrity of your design. Enjoy the benefits of insulation that sports a thermal barrier between spaces that also functions as sound proofing.

SUPERIOR PERFORMANCE AND ELEGANCE

Sing Core’s versatility cannot be matched in terms of appearance, function, lightweight and superior strength raising the bar for quality, durability, sound deadening, quick and easy installation.

Aesthetically, your Sing Core wall partitions can host nearly any exterior surface material that is available, including soft fabrics, any wood species available, aluminum, ceramic, concrete, fiberglass, stainless steel and is even available in fire-retardant and bullet-proof varieties.

LARGE, OVERSIZE OUR SPECIALITY

You’ve never had access to a more effective room divider for your home, office or commercial space; and when it comes to supersized wall divisions, Sing Core says, “no problem.” We provide systems that have operable partitions that are 37 feet tall, and we welcome any design challenges that architects or designers might be struggling with.

Confidently, we routinely provide the best solutions for oversize applications up to 50 feet high, that can be guaranteed true flat, resistant to bend, warp, twist, crack and can be structurally guaranteed for 50 years.

Plus, compare the advantages of a partition wall system that can be any height, yet a fraction of the weight. That means less transportation costs, no heavy equipment is necessary for installation, significantly less strain on the hardware and structure and fewer on the job injuries. That’s why you’re likely to see Sing Core in New York City and around the world.

ANY APPLICATION GUARANTEED

In commercial settings, airports, warehouses, schools, church and religious institutions, hotels, convention centers, ballrooms and banks Sing Core moveable wall partitions excel in performance, dimensional stability are lightweight, Eco-friendly and a fraction of the price of other commercial partition systems.

Sing Core moveable walls are the most thermally efficient, lightweight curtain wall resistant to contraction and expansion for energy savings and guaranteed true flat, whether exterior or internal curtain panels.

Sing Core provides the best demountable wall solution for an extensive range of applications, including: educational, corporate, healthcare, manufacturing and other controlled environments and – in comparison to other wall systems that can take days to assemble a wall system – the Sing Core modular advantage ensures quick and easy installation with very little labor or equipment needed. Your Sing Core room partitions can be installed in minutes.

Sing Core provides the best demountable wall solution for an extensive range of applications, including: educational, corporate, healthcare, manufacturing and other controlled environments and – in comparison to other wall systems that can take days to assemble a wall system – the Sing Core modular advantage ensures quick and easy installation with very little labor or equipment needed. Your Sing Core room partitions can be installed in minutes.

Sing Core partition walls can be configured to be mobile or foldable room dividers that can be flat-packed instantly transforming any area into multiple partitioned spaces achieving maximum utilization of your precious floor space.

IMPROVE OFFICE DESIGN AND FUNCTIONALITY

Your office décor and functionality will exponentially impact your office design by using Sing Core’s room partitions and cubicle walls. These Eco-friendly, lightweight, yet stronger than steel office solutions are the best office design ideas to achieve more productivity from your workspace. By simply adding our wall partitions, your office layout is maximized by installing the partition walls that make all the difference.

Even in heavily cubicle-laden environments, Sing Core offers cubicle walls for sale that are far more effective and much better than other office partitions as these room partitions are more insulated and have acoustic separation qualities that are not seen in other traditional office partition walls. The Sing Core cubicle wall panels help to maximize your office design ideas creating superior workstations while retaining the integrity of your office layout.

Using Sing Core’s panel partitions and dividers, you can easily modify your existing space to achieve maximum efficiency in your office space and increase privacy while your company expands. This is an effective, inexpensive alternative to having to lease out cheap office space while experiencing growing pangs. Easily customizable to any office configuration, the systems can include cubicle dividers and partition separators, creating unique and cost-effective alternatives within your existing space.

Using Sing Core’s panel partitions and dividers, you can easily modify your existing space to achieve maximum efficiency in your office space and increase privacy while your company expands. This is an effective, inexpensive alternative to having to lease out cheap office space while experiencing growing pangs. Easily customizable to any office configuration, the systems can include cubicle dividers and partition separators, creating unique and cost-effective alternatives within your existing space.

Executive washrooms deserve the Sing Core treatment. Enjoy increased privacy, insulation and acoustic separation qualities of Sing Core in your restroom toilet partitions, bathroom partitions, bathroom stalls, restroom partition walls and commercial toilets.

YOUR MOVEABLE WALL ROOM PARTITION SOLUTION

Regardless of whether you are at work or at home, sometime you need to separate two different spaces, and other times you need the extra open space for events or activities. It’s all about maximizing the usage and potential of you available space, reducing your costs and/or increasing your quality of life without compromising lifestyle or performance.

Regardless of whether you are at work or at home, sometime you need to separate two different spaces, and other times you need the extra open space for events or activities. It’s all about maximizing the usage and potential of you available space, reducing your costs and/or increasing your quality of life without compromising lifestyle or performance.

GUARANTEED THE BEST

Only Sing Core operable partitions, curtain walls and room dividers are true flat and are guaranteed to stay flat for lifetimes. Unlike other lightweight solutions, only Sing Panels are nearly indestructible. In fact, if your Sing Panel is damaged – for any reason – Sing Core will repair your panel to its original strength.

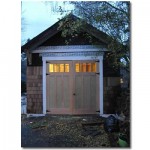

SUPERB RESIDENTIAL APLLICATIONS

In residential applications, Sing Core partitions are modern room dividers that can be used as bathroom partitions, dining room décor, privacy screens and wall partitions. Your designer or architect will re-imagine your living space as they design your room including our partition walls which are some of the most elegant room dividers in NYC. Whether your intent is to design a bedroom, home office, den or family room, these modern room dividers can also function as a folding wall.

-

-

-

-

-

-

-

-

-

lightweight stronger than steel sing sandwich honeycomb sliding door

-

-

patented Sing honeycomb sandwich closet door

-

-

Oversize Pocket Doors

-

-

GZ (Charlie) Brown

-

-

sing honeycomb lightweight glass sandwich

-

-

non warping strong honeycomb sandwich

-

-

Sing honeycomb lightweight sandwich wood

-

-

Contemporary sing honeycomb sandwich lightweight wood

-

-

Note: Costs are based on basic paint-grade panel production. Hardware, finishing and installation are not included.

Sing products have hundreds of applications but sliding doors and oversize doors are the most popular.

Sing products have hundreds of applications but sliding doors and oversize doors are the most popular.