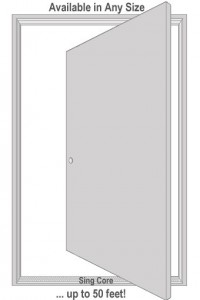

The torsion box assembly table has been the stand out project for the high-end wood worker. Regardless of the end-user’s specific application needs, there is no other method as effective as torsion box structure for building a table that can be lightweight and extremely flat.

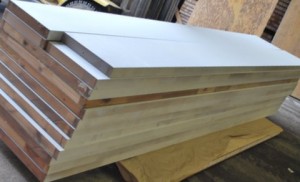

Now thanks to Sing Core and Lowe’s Home Improvement Warehouse, you can have access to torsion box plywood that is pre-manufactured for you. That’s right; all the hard work of building the torsion box core for your project has already been proudly made in the USA in the most Eco-friendly manner.

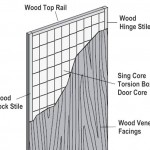

But wait; there’s more: Not only is Peter Sing’s patented torsion box plywood pre-made, but he’s taken it one-step further… Rather than leave the empty spaces inside the torsion box vacant, he’s bonded rigid recycled foam wall-to-wall for a solid substructure that is insulated, sound-deadening with unparalleled shear strength and stronger than steel pound for pound!

Finally, a lightweight high-strength building material that is the next generation of torsion box technology, empowering every woodworker to reduce costs and production time without compromising the integrity of the detailed craftsmanship.

Building your Torsion Box Workbench or Assembly Table is so easy now thanks to this revolutionary torsion box plywood from Sing Core.

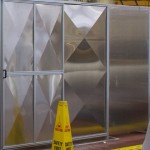

Simply bond any surface materials that you desire to the Sing Core torsion box plywood with regular wood glue and you’re ready to go. No special tools are required, as you use your regular woodworking tools treating the torsion box plywood just as you would any other plywood building material. You can make a wood table, a butcherblock workbench, stainless steel work table or project table regardless of your table plans.

Need an instant flat 4 x 8 flat surface as a temporary workspace? No problem. Balance a sheet of torsion box plywood atop a couple of chairs for an instant torsion box assembly table.

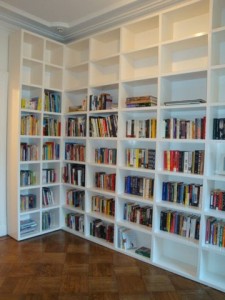

Plus, your torsion box assembly table has so many functions.

With little modification (and without compromising your original work of art) you can instantly transform your Sing torsion box work table into:

A Composite Press

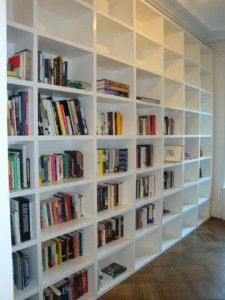

Create your own torsion box or composite panels, or even create Eco-friendly wood stave composites for effective, yet beautifully ornate wood project that look like solid wood but are incredibly strong and will last forever (Sing guarantees the products that he make using this method for 50 years).

Using this technology, woodcrafters can create wood projects with a high level of integrity that will not compromise or fail over time. Forget those disposable items from Ikea, when you can create one-of-a-kind works of art that will become valuable heirlooms for centuries.

Want to ship your creations from here to there? Now you can do so at much less cost if you use this lightweight building material, using less fuel consumption due to the lightweight attributes of your final project.

It was nearly impossible to get your hands on this revolutionary building material that is stronger than the lightweight composite material used in the aerospace industry and only a fraction of the cost.

Now, thanks to Lowe’s Home Improvement Warehouse, you can get Sing Core torsion box plywood from the Pro Desk.

Get your hands on some Eco-friendly Sing Core torsion box plywood and help make the world a better place.

Woodshop project ideas

How to build a work table

How to make a wood table