Note:

SingCore Contact Information

Office Hours: 8:30-4:30 Monday-Friday PST

Email: info@singcore.com

Phone: (360) 495-3577

Fax: (360) 495-4585

Mailing Address: P.O. Box 1691, McCleary, Washington , 98557, USA

Note:

Office Hours: 8:30-4:30 Monday-Friday PST

Email: info@singcore.com

Phone: (360) 495-3577

Fax: (360) 495-4585

Mailing Address: P.O. Box 1691, McCleary, Washington , 98557, USA

Sing Core Partners with Architects and Designers for a Better World

Lightweight does not mean weak, heavy does not mean strong; just as low cost does not mean inferior. If you are searching for lightweight panel, post and beam in wood, metal, cement board, FPR or plastic for your building design project. Newly Patented Sing core is changing the public’s previous knowledge about lightweight honeycomb sandwich material. Sing core is the only material used in such a wide range of industries and it has endless applications.

Lightweight does not mean weak, heavy does not mean strong; just as low cost does not mean inferior. If you are searching for lightweight panel, post and beam in wood, metal, cement board, FPR or plastic for your building design project. Newly Patented Sing core is changing the public’s previous knowledge about lightweight honeycomb sandwich material. Sing core is the only material used in such a wide range of industries and it has endless applications.

Sing Core’s mission is to provide superior eco-friendly product to architects who have share a common goal with Sing product to build a better World creating a healthier, green planet, benefiting all creatures and life forms for extended sustainability for the future.

Sing Core is Eco-Friendly

Sing Core is manufactured with less, energy consumed, using earth-friendly renewable veneers. No formaldehyde is used in the adhesives between the structural and sandwich facings to ensure a true green end-product.

Sing Core is Lightweight

Sing Core is extremely lightweight. Though traditional honeycomb panels and products have been effectively used in your designs, patented Sing Core weight is approximately 4-6 lbs per cubic foot. No other core or sandwich material can lay claim to the lightweight advantages of patented Sing Core.

Sing Core is extremely lightweight. Though traditional honeycomb panels and products have been effectively used in your designs, patented Sing Core weight is approximately 4-6 lbs per cubic foot. No other core or sandwich material can lay claim to the lightweight advantages of patented Sing Core.

Sing Core is Strong

Traditional aluminum, paper and/or plastic honeycomb core cell size is commonly 3/8 inch to ¾ inch. The average compression strength are 10 to 100 psi; but the smallest Sing Core grid is 2 inch x 2 inch which when tested at the University of Washington reached 660 psi. for Sing Core’s honeycomb core.

The height of Sing Core could be 6 inches or more and still has superior strength but the average height of traditional cores are limited to mostly within one inch because the taller the core, the less compression strength. That is why you never see aluminum core in a 6 inch thickness, because they fail structurally. Sing Core maintains its strength and integrity in thickness of 6 inches or more. Sing Core is redefining, “lightweight and strong.”

Sing Core’s Unlimited Applications

Sing Core panels are available in thicknesses as little as 1/8”and as thick as 8 inches in lengths of 50 feet or longer, in aluminum, plywood, even cement bprad or ceramic tile or fiberglass or any other facing. Sing Core beams have superior structural integrity and can be 20 x 12 inches thick and 50 feet long (or more).

100% of Sing Core is proudly manufactured in the USA, using local labor supporting our community. Though Sing Core is also proud to be exported to other countries with green building agendas, our hope is to provide American jobs, supporting the American economy while making America greener and more sustainable, ensuring a bright future for generations to follow.

10 Year Warranty

Sing Core exceeds current code requirements. For example, in the door industry, AWI’s guidelines dictate that a door should be less than ¼ inch flatness. Sing Core routinely builds doors that are over 10 ft or longer in length, yet staying within those 7 ft doors code requirements. Doors made of Sing Core provide 10 years of structure warranty. As a common practice in door industry, most manufacturers offer only a one year warranty.

Products made with patented Sing Core can be easily repaired without compromising it’s original strength, due to the structure of Sing Core and the bonded stress skin which when compared to solid wood and other types of solid materials would pose a significant challenge.

|

|

|---|---|

|

Craned up to Manhattan highrise.

|

Click to enlarge

|

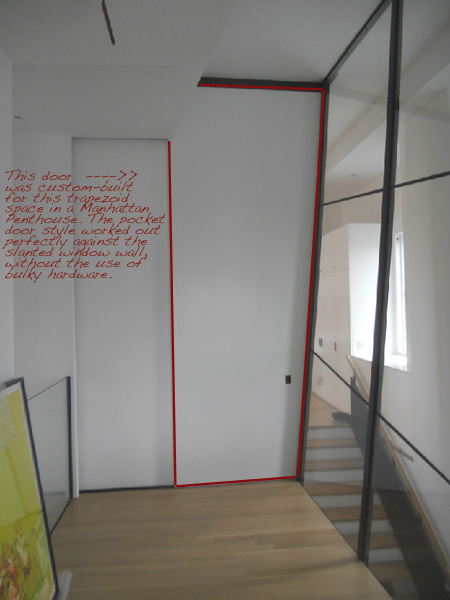

This custom made trapezoid door traveled over 2,921 miles from coast to coast, now on final leg of its journey to its new home in upscale Manhattan apartment.

We specialize in custom sizes, shapes and thickness to fit our

customer’s needs, we offer the best guarantee in the door business.

|

|

|---|---|

|

Door Open

|

Door Closed

|

As low as $50 a door for a door that will last a lifetime.

|

|

|---|---|

|

Punch proof Sing Core door.

|

Typical paper core door. (click to see more)

|

Today, the most common doors found in private residences contain a paper core. These doors are flimsy and are easily punctured, even when slightly impacted. Owners of these doors find themselves spending time and money on repairs, replacements, and installations that would not have been an issue had they purchased a door from Singcore. Singcore doors do not cost much more than paper-core doors, yet they have been tested to be at least 49 times stronger.

How secure are your doors? With our patented core, you can rest assured that our torsion box technology will stand up to harsh treatment and all weather conditions. Our doors have been thoroughly tested and have been proven to withstand the impact of a sledgehammer. There is no comparison between the stability, structure, and strength of Sing Core doors versus paper-core doors.

This is a Sing Overhead Garage Door Panel compared next to a typical steel overhead garage door panel. Same size and thickness but as you can see the steel panel buckles with only a few pounds put on it while the Sing Panel holds almost all of Inventor Peter Sings weight without any problem.

Doors do not have to be made out of steel to be rigid and strong. Sing Core doors are stronger and lighter, than steel and vinyl doors. Standard steel overhead garage doors are made of steel so thin that a golf ball can dent it. This is not the case with Sing Core doors. We offer higher quality doors at prices competitive with steel doors with quality superior to wooden doors.

Sing Core doors are more stable, provide better insulation, and are far lighter than solid wood doors. The torsion-box core holds the Sing Core door flat, ensuring that that the panel will not warp and sag like ordinary wood.

Sing Core doors are versatile and customizable. Every order is custom designed with the client’s project in mind. Each door is constructed using methods that specifically cater to our customers’ individual needs. We construct our doors using the following methods: pole barn grade, paint grade, wood grain grade, and plank grade.

The easiest way to build the best doors.

Step 1 – Apply Glue to the Skin

Step 2 – Build Solid Wood Frame

Step 3 – Install the patented Sing honeycomb torsion box core & press on the skins.

Step 4 (optional) – Cut hole for window and prepare window trim.

Step 5 (optional) – Install glass and finish the door to desired look and function.

Step 6 – Install the door onto jam.

On the left are patented Sing honeycomb stile and rail. On the right is veneer (walnut) ready for gluing onto the patented Sing honeycomb stile and rail.

Apply glue to our patented Sing honeycomb stile and rail.

Press veneer to patented Sing honeycomb stile and rail. Most honeycomb panels cannot handle the high pressure and temperatures of the hot press, Sing honeycomb can.

Stile and Rail after the veneer has been pressed on.

See how straight the patented Sing honeycomb stile and rail are, yet they are still incredibly strong and lightweight.

Drill holes to accept dowels.

Doweled and glued.

Router out the end if hardware is to be installed

Stained and ready for glass and installation.

|

|

|---|

Pictures courtesy of Robert Shaw – www.robertshawmfg.com

Doors 8′ – 7″ tall

| Sing Door Assembly | Sing Door Strength Demo |

We are exporting Sing Core to provide the tallest skyscrapers in Bangkok with the solutions to their design problems.

(Photo above, pre-export at home in the USA)

What design problems do you think they have? Mostly the same problem all large project designers run into, like the complexities of ecologically friendly, lightweight, strength and integrity over long lengths. Sing Core is the superior solution for these obstacles.

Photos here are of a container of Sing Core beams and panels used in the construction of one of the tallest buildings in Bangkok, Thailand. This is likely one of the only patented plywood product to be exported to Asian countries. Why? Much of our plywood is imported because they can manufacture it so inexpensively off-shore. In fact, their prices are so low that American companies have accused them of dumping product to bury the American wood industry, resulting in a 25% import duty on imported plywood products.

So, think about that… Asia importing Sing panels and beams… The only reason that they would do that is if it was the only way to solve their design problems; and nothing fits the bill like Sing Core.

From an export point of view, note that the shipment of product is ten times stronger than standard wood product, yet weigh 70 to 80 percent less than the equivalent plywood.

In a time when the United States is encouraging you to not to import by charging a 25% tariff on incoming plywood, why not shop at home and consider a structural technology that is far superior not only to import varieties, but nearly any other conventional construction material.

In case you are unaware of the Sing Core technology; here is a basic rundown:

The Sing Core is based on primitive torsion box honeycomb designs, but is exponentially improved upon the basic design.

Sing Core is manufactured with LESS

Our unique manufacturing process requires LESS

Sing Core panels are

That is why the supplier of high-end custom-built oversize products to the

has sought out Sing Core as their solution. Yet, we make this technology affordable, even to compete with cheap imports.

If you are currently importing substandard plywood from off-shore, shouldn’t you think about being proud to say, “Made in the USA,” reducing your costs, delivery times and providing your clients with a superior product that is not only eco-friendly but “true green”?

Spend Less Get More With Sing Core

Cecilia Story

The Nature Conservancy

“Peter and Linda along with the rest of the Sing Home team were lifesavers! They were wonderful to work with and did all that they could to meet tight deadlines without losing the flawless quality in their work. I look forward to collaborating with them again.

All the best,”

Jane

Robert Drake

“I am a returning customer of yours from last year. I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.”

Robert Drake

Robert Drake Construction:

Yes, your doors were exactly what my client was looking for and no one else in the county had them. Please feel free to give my name, cell phone number, email address and any other information you want to your potential customer. They are welcome to call anytime.

Sincerely,

Robert Drake

Robert Drake Construction

125 Year-old Church Door Replacement

These doors were replacements for original doors on our 125-year-old Church in a historic village in upstate NY. The size of the doors were quite unique, so buying premade door slabs was not an option, and custom doors were well outside of our budget. For the cost we were quoted for one set of doors, we were able to build and hang all 3 sets with the end product being a good reproduction of the original solid doors.

The Sing Core panels allowed us to get an insulated door, in our custom size, and I was able to apply 1X lumber and trim on both sides which allowed me to recreate the look of the original stile and rail look of the existing doors. The panels were straight and flat, and made a great substrate for the trim. We painted the outside in the traditional red color common on Methodist churches, and stained the inside to match to paneling in the vestibule.

Bruce

“Thanks for the follow-up, I’m very pleased with the panels an how they have worked out with my project. As you can see, I framed them with poplar molding, glued in place with waterproof glue, and painted them to seal against the weather.

I brag on these panels all the time and everyone is always impressed.

Thanks again,”

Steve

“Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.” Amy

“ I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.” Robert D.

“I love your product!” Kevin B.

—

“Your product is the bomb diggity!” Smithy D.

“We had purchased two of your panels to use as sliding doors for one of our steam rooms. To date they are working great.” Kenny B.

Chad Thompson

Trellis Interiors

Sing Homes,

Of course, please feel free to give them my name and cell phone.

Thank you,

Chad

| DeweyWebster |

|

Cloud House |

You bet! We love your doors!!

Regards

Dewey

Direct quotes from recent customer:

What did you think of the panels when they arrived?

They looked just as I expected. High quality workmanship and to my

exact specifications.

What was it like working with them to get the design you wanted?

Very easy to work with. The panels were totally flat and square.

What did you think of the panel’s weight in comparison to their size?

Weight came in as expected which is very light compared to a solid wood

door.

Do you think that our garage door panels are equal in strength to

standard garage panels?

I think these panels are stronger than standard garage doors.

Definitely stiffer.

If you were to do another project similar to this would you buy our

garage door core panels again?

YES.

Would you tell other people where you got your door cores from?

YES.

Please tell us in your own words about your experience with our panels.

I have nothing to complain about with regards to the entire

experience. Customer service while ordering the doors was top notch.

Price was great. Shipping/delivery was easy. Fabrication of my doors

was straightforward.

-Kevin B., California

—

Thanks for getting in touch.

Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.

If you are interested, i think you could market this product to artists.

I don’t think there is anything on the market in terms of oversize drawing boards.

Thanks again.

Amy

A Testimonial from Dave Kellog – Dave Kellog is the first Sing Home customer to build in Wyoming. He’s beginning with a 24′ x 36′ multiple use cabin, and will later add a large Sing Timber residence. Dave writes:

“The project is going extremely well… the building is 24′ x 36′, and after the foundation and floors were poured, I got to wall height (10’3″) in just seven days… All work has been completed by me alone…so this has been a one person operation. I have had a lot of interested folks stop by, all very curious about the Sing Timbers. I think when I get the house and garage built, I may spec one just to see how well it sells! It has been a lot of fun so far, just like building with big Legos, and boy is this thing solid! I really like the Sing system, it is wonderful for ‘do it yourselfers’, especially if it is only yourself doing it!”

Dave Kellog

Lander, Wyoming

A Testimonial from Bob & Linda Freeman – The Freemans built two Sing Homes, a 24′ x 24′ cabin w/ garage, and a 2000 s.f. prow front home. They write:

“We built the garage/bonus room last year because our home in Bellingham was still for sale. We wanted to see if Sing Logs was what we really wanted. It turned out better than we thought it would. They are easy for people who know nothing about construction work. They look great and the logs are very strong…stronger than conventional post and beam. How do we know? We are now building the house attached to the garage and I had to cut the door opening. It was really difficult to knock the door out, even after it was cut with a chain saw! The logs also make the interior quiet, and through the winter, it was toasty warm with just a propane stove.”

Bob and Linda Freeman

Mazama, Washington

Chuck Dudley – Pioneer Home Services – I was introduced to the Sing Home concept about 5 years ago and have since built 4 of them, with 2 more coming up.

I was introduced to the Sing Home concept about 5 years ago and have since built 4 of them, with 2 more coming up in the Spring. After having built with their product, I do not want to build again using conventional framing. There simply is no comparison in quality, stability and strength, longevity, energy efficiency, or beauty. The cost is comparable to a custom stick-built home, but with so many more advantages. There is also a financial advantage with a Sing Home. As soon as the home is completed it can easily be worth more than a third more than it cost to build. Can I recommend a Sing home? Absolutely I can! I stake my reputation of 35 years in construction on the Sing Home product. Chuck DudleyPioneer Home Services

|

|

|

Here is a butcher block table top we made custom for a client, the beauty of the product speaks for itself!

Cecilia Story

The Nature Conservancy

“Peter and Linda along with the rest of the Sing Home team were lifesavers! They were wonderful to work with and did all that they could to meet tight deadlines without losing the flawless quality in their work. I look forward to collaborating with them again.

All the best,”

Jane

Robert Drake

“I am a returning customer of yours from last year. I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.”

Robert Drake

Robert Drake Construction:

Yes, your doors were exactly what my client was looking for and no one else in the county had them. Please feel free to give my name, cell phone number, email address and any other information you want to your potential customer. They are welcome to call anytime.

Sincerely,

Robert Drake

Robert Drake Construction

2011

“Thanks for the follow-up, I’m very pleased with the panels an how they have worked out with my project. As you can see, I framed them with poplar molding, glued in place with waterproof glue, and painted them to seal against the weather.

I brag on these panels all the time and everyone is always impressed.

Thanks again,”

Steve

“Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.” Amy

“ I ordered 12 closet doors from your company and my client was 1000% satisfied. I know 1000% does not make mathematical sense, but he is really proud of his closet doors.” Robert D.

“I love your product!” Kevin B.

—

“Your product is the bomb diggity!” Smithy D.

“We had purchased two of your panels to use as sliding doors for one of our steam rooms. To date they are working great.” Kenny B.

Chad Thompson

Trellis Interiors

Sing Homes,

Of course, please feel free to give them my name and cell phone.

Thank you,

Chad

| DeweyWebster |

|

Cloud House |

You bet! We love your doors!!

Regards

Dewey

Direct quotes from recent customer:

What did you think of the panels when they arrived?

They looked just as I expected. High quality workmanship and to my

exact specifications.

What was it like working with them to get the design you wanted?

Very easy to work with. The panels were totally flat and square.

What did you think of the panel’s weight in comparison to their size?

Weight came in as expected which is very light compared to a solid wood

door.

Do you think that our garage door panels are equal in strength to

standard garage panels?

I think these panels are stronger than standard garage doors.

Definitely stiffer.

If you were to do another project similar to this would you buy our

garage door core panels again?

YES.

Would you tell other people where you got your door cores from?

YES.

Please tell us in your own words about your experience with our panels.

I have nothing to complain about with regards to the entire

experience. Customer service while ordering the doors was top notch.

Price was great. Shipping/delivery was easy. Fabrication of my doors

was straightforward.

-Kevin B., California

—

Thanks for getting in touch.

Yes, the panel worked great. As mentioned when I ordered it, I used it as a drawing board.

Standard drawing boards for artists–at least the lightweight variety–are not very large.

I needed something that was very light and perfectly flat that would hold large pieces of paper and would also accept pushpins.

If you are interested, i think you could market this product to artists.

I don’t think there is anything on the market in terms of oversize drawing boards.

Thanks again.

Amy

A Testimonial from Dave Kellog – Dave Kellog is the first Sing Home customer to build in Wyoming. He’s beginning with a 24′ x 36′ multiple use cabin, and will later add a large Sing Timber residence. Dave writes:

“The project is going extremely well… the building is 24′ x 36′, and after the foundation and floors were poured, I got to wall height (10’3″) in just seven days… All work has been completed by me alone…so this has been a one person operation. I have had a lot of interested folks stop by, all very curious about the Sing Timbers. I think when I get the house and garage built, I may spec one just to see how well it sells! It has been a lot of fun so far, just like building with big Legos, and boy is this thing solid! I really like the Sing system, it is wonderful for ‘do it yourselfers’, especially if it is only yourself doing it!”

Dave Kellog

Lander, Wyoming

A Testimonial from Bob & Linda Freeman – The Freemans built two Sing Homes, a 24′ x 24′ cabin w/ garage, and a 2000 s.f. prow front home. They write:

“We built the garage/bonus room last year because our home in Bellingham was still for sale. We wanted to see if Sing Logs was what we really wanted. It turned out better than we thought it would. They are easy for people who know nothing about construction work. They look great and the logs are very strong…stronger than conventional post and beam. How do we know? We are now building the house attached to the garage and I had to cut the door opening. It was really difficult to knock the door out, even after it was cut with a chain saw! The logs also make the interior quiet, and through the winter, it was toasty warm with just a propane stove.”

Bob and Linda Freeman

Mazama, Washington

Chuck Dudley – Pioneer Home Services – I was introduced to the Sing Home concept about 5 years ago and have since built 4 of them, with 2 more coming up.

|

|

|

Here is a butcher block table top we made custom for a client, the beauty of the product speaks for itself!

Due to these Sing Canvas Artist Panels being so light weight, shipping via air freight to the Bahamas airport was simple, easy and cost effective. This artist canvas measures 4 ft. x 10 ft. x 3 inches with 1/4 inch plywood veneer with eucalyptus. They are now on permanent display at the Grand Bahama International Airport.

Testimony from the artist Jane Kim:

Peter and Linda along with the rest of the Sing Home team were lifesavers! They were wonderful to work with and did all that they could to meet tight deadlines without losing the flawless quality in their work. I look forward to collaborating with them again.

All the best,

Jane

Here’s just one example of a home made entirely of only Sing Core products. The walls, the floors, posts, beams and doors… everything made of Sing Core except the glass and the hardware. Here are examples of homes that were built live while thousands of people watched in amazement at how quickly and easily it was manufactured without any heavy equipment different home shows.

For other ideas, see more of our Sing Homes.