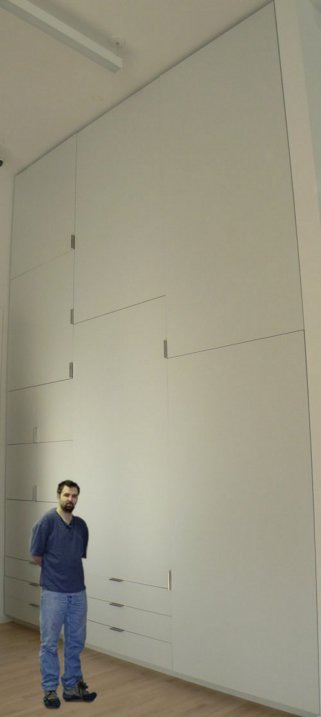

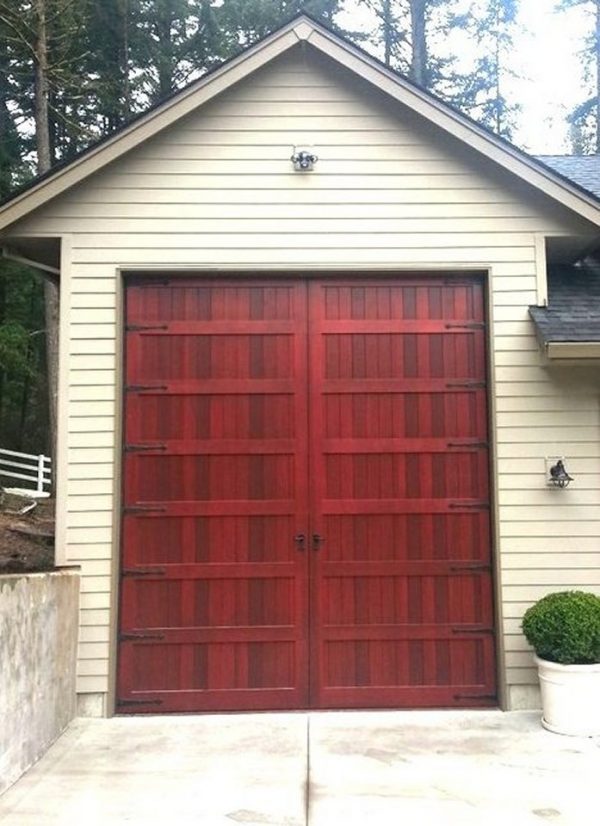

Specializing in oversized doors exterior doors are often the most problematic due to their potential oversized door failure in exterior applications, SingCore is the answer.

Specializing in oversized doors exterior doors are often the most problematic due to their potential oversized door failure in exterior applications, SingCore is the answer.

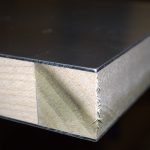

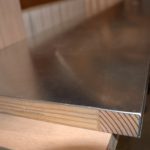

Any oversized door with premium SingCore inside could be guaranteed for 50 years.

Guaranteed for what? Warp-free performance and full structural integrity guaranteed. Only doors with SingCore inside can offer such a warranty, even oversized doors exterior with high precision and performance.

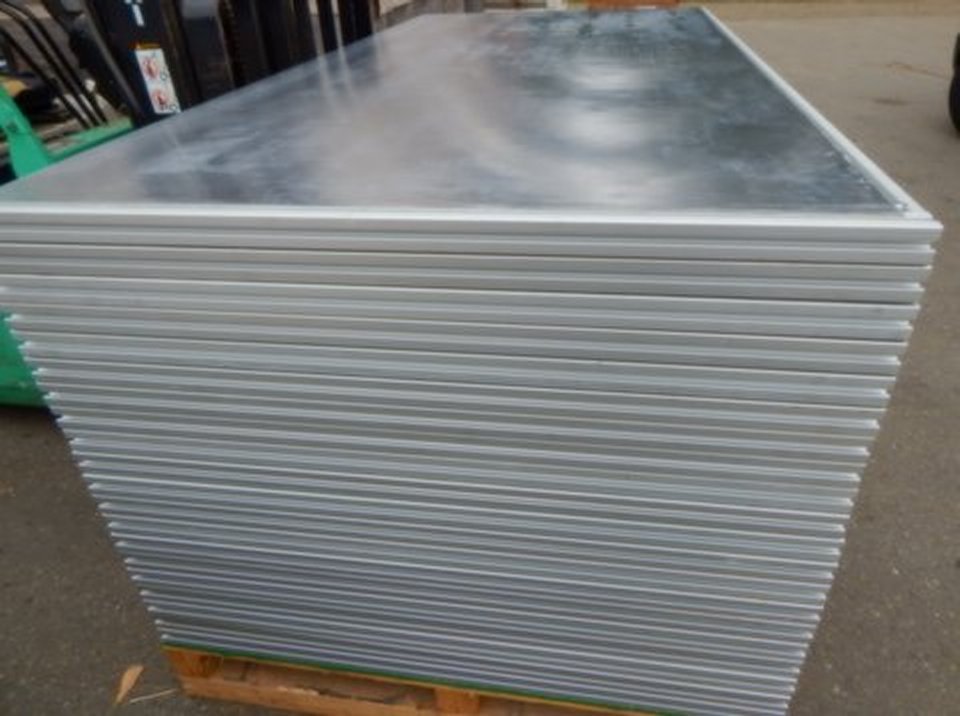

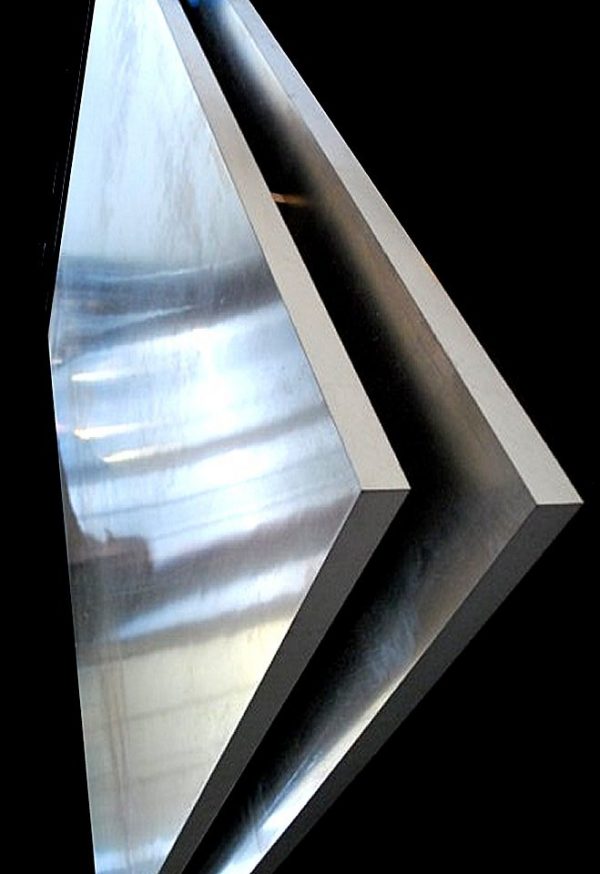

Oversized Doors Exterior Metal Door

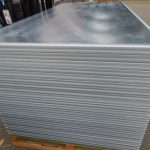

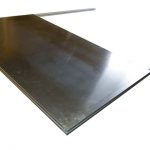

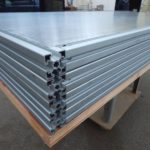

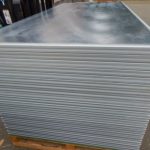

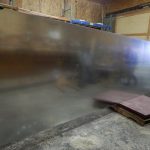

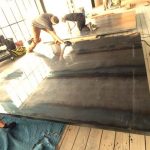

The patented SingCore process produces Eco-friendly large oversized doors exterior metal doors that are lightweight and stronger than steel pound for pound. While we assist architects, engineers, designers and door manufacturers to create the best oversized doors exterior metal door made of any metals such as aluminum, brass, copper and other types of metals, the most popular metal door we produce are steel doors.

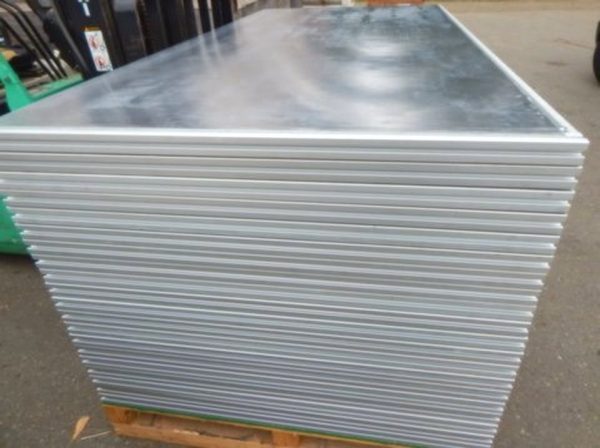

We are proficient in the ecologically respectful manufacture of all kinds of oversized doors exterior steel doors using all kinds of steel including cold rolled steel doors, diamond plate steel doors, galvanized steel doors, hot rolled steel doors, stainless steel doors, and more.

Oversized Doors Exterior Steel Door

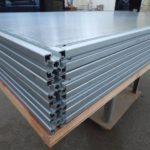

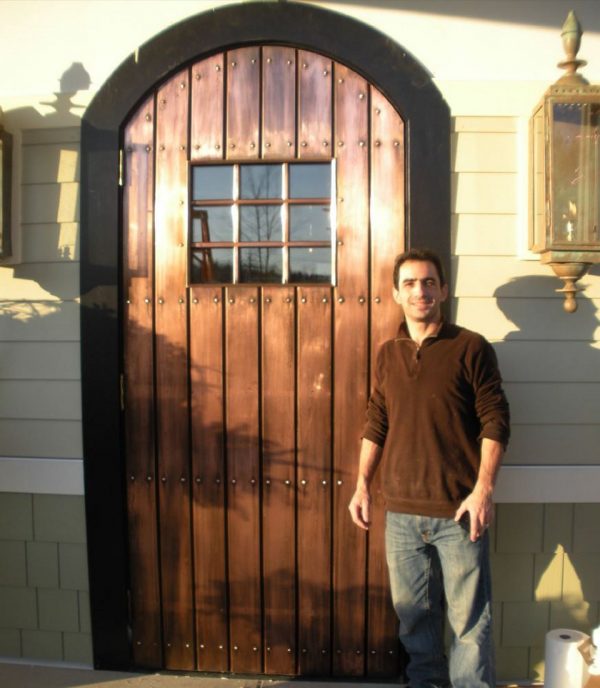

Our most popular oversized doors exterior steel door is the steel door with window. The large oversized steel doors with window cutouts are used in a variety of applications including being used as exterior security doors, followed by oversized doors exterior steel double doors.

Steel exterior security doors have the benefits of being lightweight steel as well as having the insulation characteristics of SingCore inside offering added safety, security, climate control and sound deadening qualities.

Exterior steel double doors are twice as impressive as their single steel door alternative because they are double exterior steel doors. Steel double doors exterior steel can be specified and built to custom architectural or engineered specifications.

So, if you’re looking for a steel double entry door, SingCore’s oversized doors exterior steel double entry door may well be the best steel entry doors made in the USA, if not the world.

Fiberglass Entry Doors with Sidelights

Next up are our fiberglass entry doors with sidelights that are becoming more popular among our homes located in climate sensitive areas. In regions with a wide range of weather exposure or experience a great deal of extreme weather conditions, fiberglass entry doors with sidelights offer substantial features sought out by end users.

Next up are our fiberglass entry doors with sidelights that are becoming more popular among our homes located in climate sensitive areas. In regions with a wide range of weather exposure or experience a great deal of extreme weather conditions, fiberglass entry doors with sidelights offer substantial features sought out by end users.

Fiberglass oversized doors exterior styles also include the front door with window, arched front door, double front doors with glass and oversized exterior doors.

Regardless of the type or style of your oversized doors exterior requirements or desires, note that SingCore door blanks are able sport any size window glass openings as well as support and bond to any flat building material for the ultimate in design and performance spanning a wide array of possibilities.

Replace Exterior Door

It is common for us to receive calls in the field for building replacement doors for existing builds or renovation of classic traditional doors, as well as architectural replacement doors in new projects in the process of being built.

Whenever the engineers, architects, builders, contractors, designers or the end client becomes aware of the SingCore attributes, they consider specifying all their doors have SingCore inside, especially if there is a large oversized door issue that may result in expensive installation and maintenance costs over time.

If you want your oversized doors exterior attributes to include:

Lightweight

Lightweight- High strength

- Eco-friendly

- Warp-free

- Insulation

- Climate control

- Noise dampening

- All backed by a 50 yr guarantee

Only SingCore can deliver all this and so much more.