If you’re looking for the best in large sliding door design, you’ve come to the right place. Sing Core specializes in creating the ultimate sliding door experience. That’s why you see Sing large sliding doors everywhere on planet earth and beyond, from beneath the sea (US Navy) to outer space (NASA) and everywhere in between.

Sliding Doors

The deal with sliding doors is that you want your sliding doors to remain straight and true throughout their service life. Architects, designers and end users face the issues associated with the problems associated with sliding doors, such as,

Problems with Sliding Doors

The first problem with sliding doors is that they tend to move (warp, bend, twist or cup) compromising the doors’ performance. Especially in the case of sliding doors because they hang parallel to a wall (like sliding barn doors), another door (such as double sliding doors) or within a wall (like sliding pocket doors). If the door does not stay straight, it can wreck either the sliding doors or the surfaces they slide against, or both.

Heavy Sliding Doors

One way to deal with the problem of warping sliding doors is to build them using extremely heavy and warp resistant materials, such as steel, which introduces whole new set of problems, which will increase maintenance costs over the life of the door. Even though the heavy sliding door may not warp, it will require expensive heavy duty hardware (which can cost many times the price of the door itself) which can easily be compromised due to regular use, as well as the added stress of using a heavy door, will add stress and strain to the frame and structure, also requiring additional maintenance over time. Some architects and designers might consider using a lighter weight metal, such as,

Aluminum Sliding Doors

Of course, aluminum sliding doors make more sense; though contemplating the use of solid aluminum sliding doors will still introduce the problem of heavy weight. One way to manage the weight of the door is to use a honeycomb material, such as aluminum honeycomb, paper honeycomb or some other type of honeycomb material inside the otherwise hollow core sliding door. The only problem with that is that as you introduce a lightweight substrate, the door begins to warp again, especially if they are exterior sliding doors.

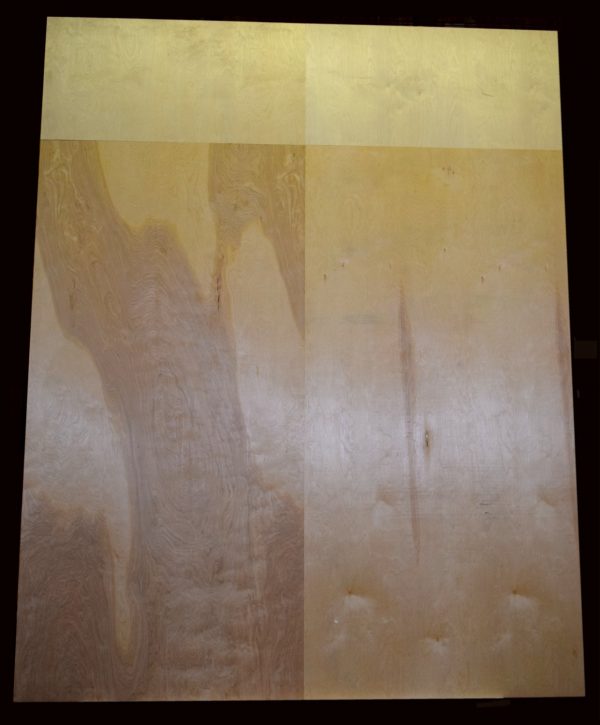

Wooden Sliding Doors

Ah, the elegance and beauty of natural wood. We love it and exotic wood grains can instantly garner the awe and attention of anyone spying a large sliding door made of wood. This is why many large sliding doors are wooden sliding doors. As magnificent and appealing as they are, wood is the worst culprit of all, because it can barely sit still for as long as you can. Due to wood’s natural characteristics, it is most prone to warp, bending, twisting and cupping, because even separated from the tree, it still fights for survival and the grain will either expand or contract due to the elements it is presented with. Exterior doors are the most problematic because one side faces the interior space, while the other side faces the elements outside, a perfect recipe for door warp.

Large Sliding Doors

The bane of perplexed custom sliding door manufacturers is the additional challenges with doors which are taller than 7 ft. tall and wider than 3.5 ft. Very few, if any, custom door manufacturers or millworks will even consider guaranteeing a door over seven feet tall. Why? Because they know it is going to fail, and they will be called upon to deal with it. In most cases, the job as a whole will have a warranty on the work done, with the exception of the large sliding doors which are normally noted as exceptions to any warranty that might cover the rest of the job. That is, unless you know the answer to the problems associate with large sliding doors.

Sliding Door Design Problems Solved

Architects and engineers are constantly perplexed with the problems associated with sliding doors, fortunately an Eco-friendly composite solution made in the USA, helps to solve the problems associated with faulty sliding door design. Patented Sing Core, along with their true flat door team, can help to create sliding doors that will remain straight and true far beyond the service life of any other sliding doors. By working with Sing Core’s design staff a combination of Sing Core and patent-pending sliding door stiffening solutions can create perfect sliding doors that are lightweight, high strength and can be guaranteed not to warp, bend, twist, cup or otherwise fail for 50 years.

The Perfect Large Sliding Doors

The best custom door manufacturers and millworks who offer long warranties on their large doors have a secret inside each one of their high end professional sliding doors: Sing Core inside. A properly designed and built large sliding door with patented professional Sing Core inside can be guaranteed not to warp, bend, twist or otherwise fail for 50 years. How do you know if you have the best large sliding doors in the world?

It’s easy; just see if your sliding doors have the following Sing Core sliding door characteristics:

Eco-friendly

Lightweight

High-strength

High Precision

Fully Insulated

Warp-free

Sustainable Long Life

Made in the USA

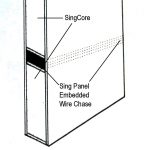

When your sliding door company claims they are providing you with the best sliding doors possible, you can rest assured your large sliding doors will pass the perfect sliding door test by being manufactured using Eco-friendly Sing Core which uses less energy, renewable, sustainable and non-toxic ingredients to create its vertical grain torsion box composite core. Sing Core sliding door core is lightweight, weighing approximately 10% the weight of solid wood-based door cores. The high strength of Sing Core outperforms any other sliding door core material, independently tested to rate at least 660 PSI, which makes it stronger than steel pound for pound.

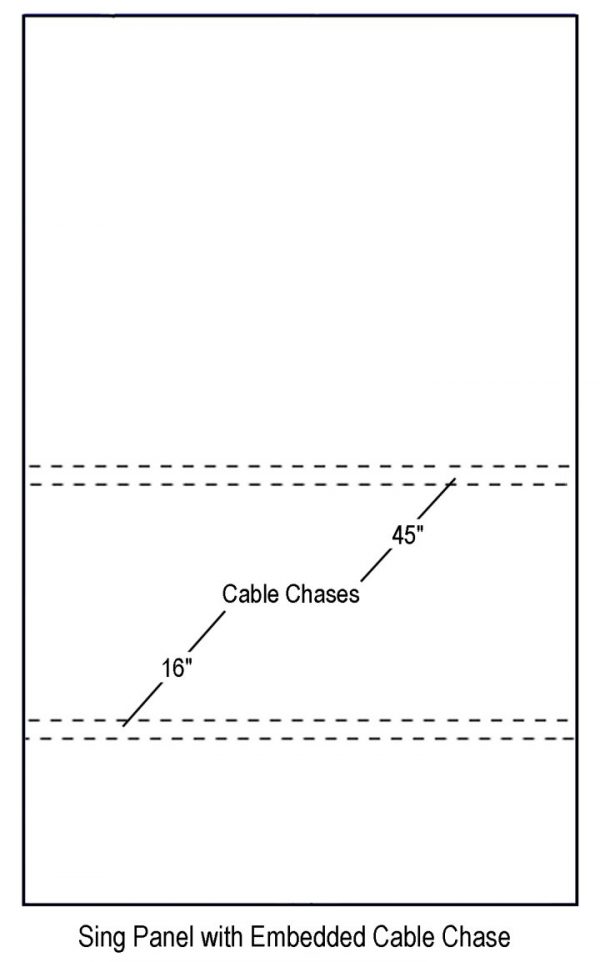

Other sliding door core materials do not create a high precision base due to product production inconsistencies or welding, while Sing Core is the most high precision at +/- .006 inch. Only perfect sliding doors manufactured with Sing Core inside can remain warp-free. Sing Core is fully insulated imbuing the best sliding doors with climate control (R rating) and sound deadening qualities (STC rating*) for greater safety and security. Professional Sing Core sliding doors can be guaranteed not to warp, bend, twist, cup or otherwise fail (including full structural warranty) for 50 years, assuring your large sliding doors sustainable long life, while being proudly made in the USA.

Yes, you read that right. The perfect large sliding doors are the only ones that have a

50 Year Guarantee

Now you know you have the perfect large sliding doors, if they have Sing Core inside.

Other Types of Sliding Doors

You can enjoy all the available types and styles of large sliding doors that can accommodate and size without compromising strength or weight, such as sliding French doors, patio sliding doors, mirror sliding doors, folding sliding doors, sliding pocket doors, double sliding doors and sliding folding doors, just to name a few.

Now that you know how to determine what are the best large sliding doors are supposed to be, you can get the perfect large sliding doors wherever you find custom sliding doors for sale and tell them you want all your doors to have, “Sing Core inside.”

Sing Core and More

Patented Sing Core enables architects and designers to let their creative genius run wild by incorporating Sing Core in all their projects, not just for large sliding doors as Sing Core is also available in panels, posts and beams to enhance the capabilities of any large scale project which may encounter problems associated with strength and weight.

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.