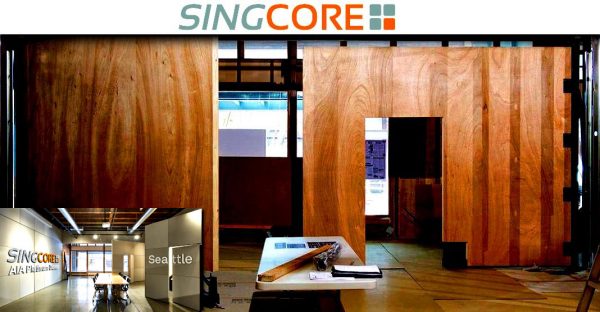

When it comes to large entrance doors, one pivot entry door comes to mind: That beautifully big pivot entry door with natural wood grain is so pleasing to the eye.

Q: How in the world do they keep such an enormous exterior wood door from warping?

A: With Sing Core inside.

Large entrance doors instantly garner attention and add curb appeal to any project, but featuring pivot doors as your entrance door makes an even greater impact on anyone who encounters such an enormous work of art.

Pivoting doors are more in demand because they attract attention like a magnet, especially if your pivot entry door is made of natural wood grain, because this just cries out: “Constant maintenance required” due to changes in the environment which causes such a big wood pivot door to warp. It doesn’t make the pivot door any less beautiful, but the regular maintenance can make such a door far less affordable over time.

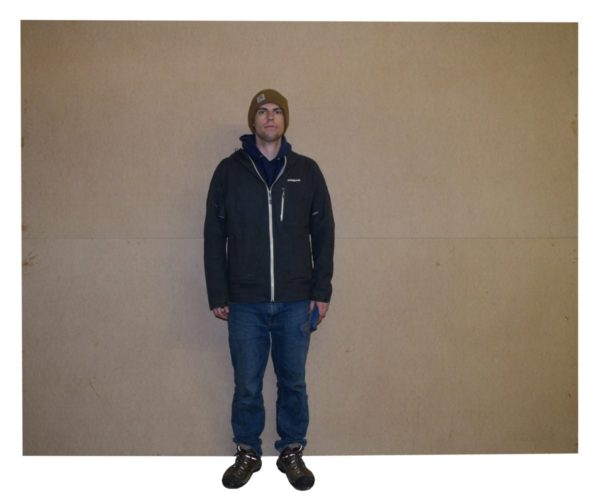

That’s where patented Sing Core and inventor Peter Sing’s patent-pending anti-warp devices come to save the day. Sing, also the president of Sing Core, uses his latest technological advancements to help any pivot door company, millwork, or custom pivot door manufacturer build pivot entry doors of immense size quickly and easily without threat of failure or warping.

The idea of a new generation of warp-free modern entry doors is foreign to pivot door designers and engineers of yesteryear, that is, unless they have already heard about – and use – Sing Core inside their most important pivot entry door jobs.

How to Build a Warp-free Pivot Entry Door

Solid wood entry doors present the greatest numbers of challenges for the craftspeople tasked with transferring the architectural pivot door dreams into reality. We love the natural wood grain but it’s tendency to move at the slightest change in the environment creates problems. So, starting with Sing Core is the perfect place to start if you want to put your worries associated with exterior pivot doors behind you.

For years, Sing has been supporting the best of the best in contemporary architecture and designs, as well as the biggest most powerful pivot door companies in the world with the solutions to the problems associated with pivot entry doors over seven ft tall and three-and-a-half ft wide. Once you know how Sing’s core works, you, too, will know how to build a warp-free pivot entry door.

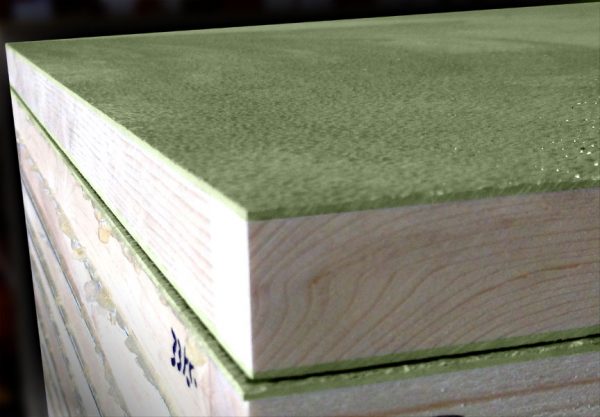

If you look deep inside the structure of Sing’s warp-free pivoting doors, you will find that the first component is torsion box, only the grain is oriented vertically instead of horizontally as is the case for traditional torsion box. Sing also keeps the structure grids of the torsion box very small, like two to three inches. Then, he fills the voids (the open centers of the individual torsion boxes which is normally left hollow) with recycled rigid foam.

Using formaldehyde-free adhesive, Sing cold-presses the composite materials together, sandwiched between two stress skins to create the solid hybrid warp-free pivot entry door blanks which are found inside the best high-end doors.

Even so, Sing’s warp-free technologies do not end there. Pivot entry doors are especially challenging due to potentially having one side of the door facing the elements, as in the case of exterior pivot doors, while the other side faces the structure’s interior. This is the perfect recipe for warping pivot doors.

Sing has a True Flat Team of door engineers in-house who assist in the design and creation of the core in such a way so as to account for all the challenges each pivot entry door may face. For instance, solid wood entry doors present the most problems, but not for Sing’s team.

Wood Entry Doors

They go to work, taking into account all the details of the door, including how the door will be used, what direction will it face, at what altitude will it make its home, what weather conditions will it be subject to, how will it be operated, suspended, and secured? As well as what

Sing Core can be found inside modern entry doors from beneath the sea (US Navy) to outer space (NASA) and everywhere in between because it is the highest precision (+/- .006 in.) Eco-friendly fully insulated (R3.5 to R6.5), lightweight (1/3 or less the weight of other solid wood-based cores), high strength (660+ PSI, stronger than steel pound for pound), impact resistant, climate control, and sound deadening pivot door substrate.

Any of Sing’s pivot doors could be made from any flat building materials, such as any type of natural wood grain, aluminum, brass, cement, concrete, cold rolled steel, copper, fiberglass, Formica, FRP, glass, HPL, Kevlar, laminates, Masonite, MDF, stainless steel, veneers, and just about anything you could imagine.

Also, your pivot entry doors are not limited in size, as Sing’s door blanks are featured in really big pivot doors up to 50 ft or more, and each can still be covered by Sing’s 50-year warp-free guarantee.

50-YEAR GUARANTEE

Sing offers the only way to build doors in the world which can be safely and securely guaranteed not to warp, bend, twist, cup, or otherwise fail, (including full structure warranty and guaranteed against delamination) for a full 50 years.

This is the best pivot entry door guarantee in the world, another reason why biggest and best door makers use it.

The world is changing, growing, and expanding at a rapid rate, and Sing’s pivot doors are changing the way architectural pivot doors of any type or style are being made.