See the Sing Core Metal Door Gallery

About Metal Doors with Sing Core Inside

Metal doors which are made using the patented and patent-pending Sing Core technologies are celebrated around the world as being the best metal doors in the world.

Why Do You Need Sing Core Inside Your Metal Door?

Metal Door Problem

Its well-known metal doors are neither Eco-friendly nor sustainable solution and they have the potential to fail more often than not for a variety of reasons. Metal doors warp when hit by the sun’s rays, or exposed to heat or cold, and if there are varying environments on either side of the metal door, such as an exposed exterior metal door, you know trouble is not far away. Also metal doors are extremely heavy which causes hardware or the structure to fail due to added stress and strain due to the heavy weight. Plus, the bigger the metal door, the more likely it will fail and require expensive maintenance calls to repair or replace.

Metal Door Solution

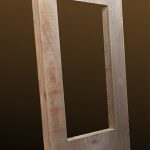

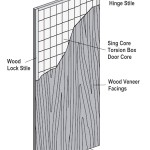

THAT is why you need Sing Core inside your door. Using Sing Core is the only way to build an Eco-friendly sustainable lightweight solid core metal door that is stronger than steel and comes with a full warp-free and structure guarantee for 50 years.

50-YEAR WARP-FREE GUARANTEE

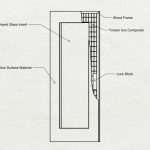

What makes a Metal Door with Sing Core inside so unique?

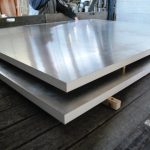

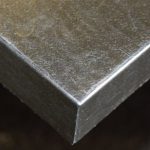

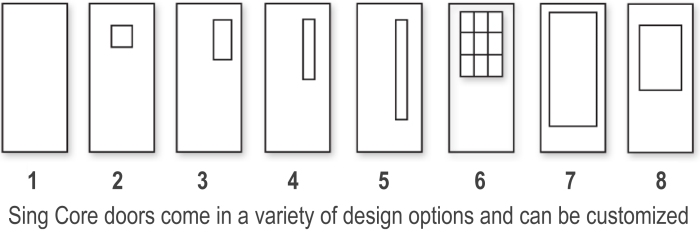

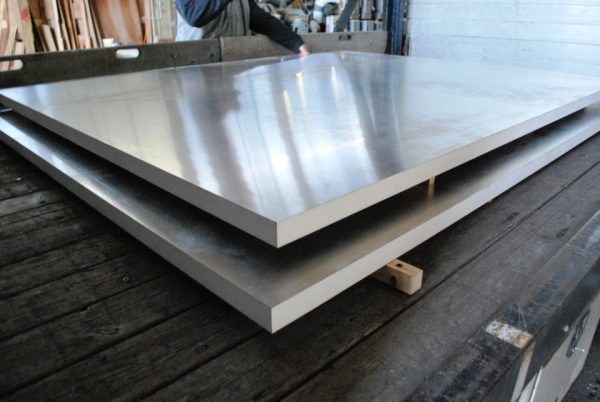

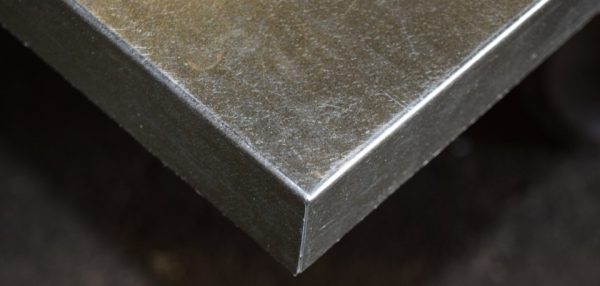

Only metal doors with Sing Core inside are lightweight, high strength, fully insulated, available in vast array of skin types such as aluminum, brass, cold rolled steel, galvanized steel, hot rolled steel, stainless steel, or any other available type of metal including metal hybrid or composite flat surface materials. Any size large oversized metal door up to 50 ft. Best metal door guarantee in the world: 50 years!

-

-

- Lightweight

- Sing Core weighs a fraction of the weight of other solid metal door cores

- Being lightweight saves the overall budget of the project

- Reducing shipping cost

- Reducing the cost of hardware (which is based on pivot door weight

- Reducing heavy equipment costs on the job site

- Reducing risk of injury during installation

- Reducing maintenance costs on the door/frame/structure over time

- High Strength

- Sing Core is lightweight, yet stronger than steel pound for pound

- Independently tested at University of Washington

- Rated at 660+ PSI

- Able to span longer distance with little deflection

- Able to support unsupported load stress

- Fully Insulated

- Patented Sing Core is pre-insulated

- Insulation for climate control

- Your choice of R 3.5 or R 6.5 insulation value

- Insulation for sound deadening (used in sound proof doors)

- Insulation for added privacy, safety, and security

- Vast Array of Skin Types

- Metal Door Skins

- Any available flat metal building materials including responsibly sustainable use of

- Aluminum

- Brass or bronze

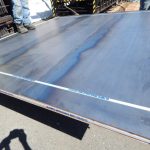

- Cold rolled steel

- Copper

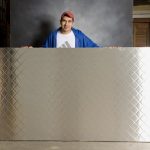

- Diamond plate

- Galvanized steel

- Hot rolled steel

- Stainless steel

- Any available flat metal building materials including responsibly sustainable use of

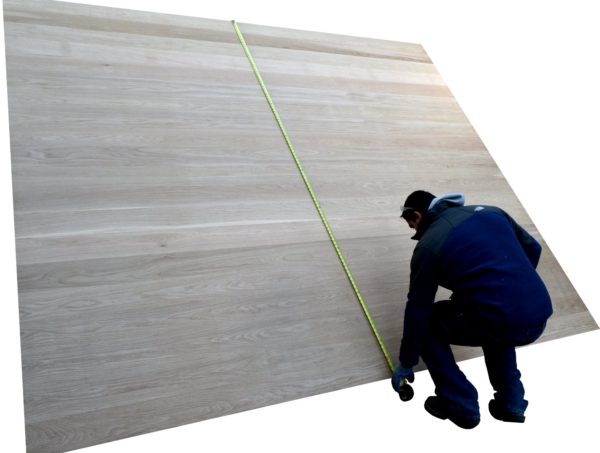

- Not limited to metal, could include other flat sheet goods

- Veneer

- Plywood

- Marine grade

- Generic

- Domestic A/B plywood

- LVL

- MDF

- and any others available per architectural specifications

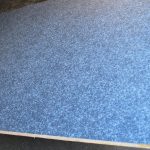

- Alternative and Hybrid Skins, such as

- Cement

- Concrete

- Fiberglass

- Plastic

- FRP

- Kevlar

- Formica

- Masonite

- and any others available per architectural specifications

- Metal Door Skins

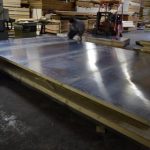

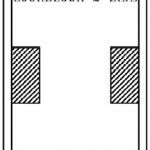

- Any Size Door Can be Made Better with Sing Core Inside

- Any door up to 50 ft. tall, or more

- Any door up to 50 ft. wide, or more

- All attributes are imbued in any size of door made with Sing Core inside

- The Best Guarantee in the Pivot Door Industry

- 50-year warp-free guarantee

- 50-year structure guarantee

- Lightweight

-

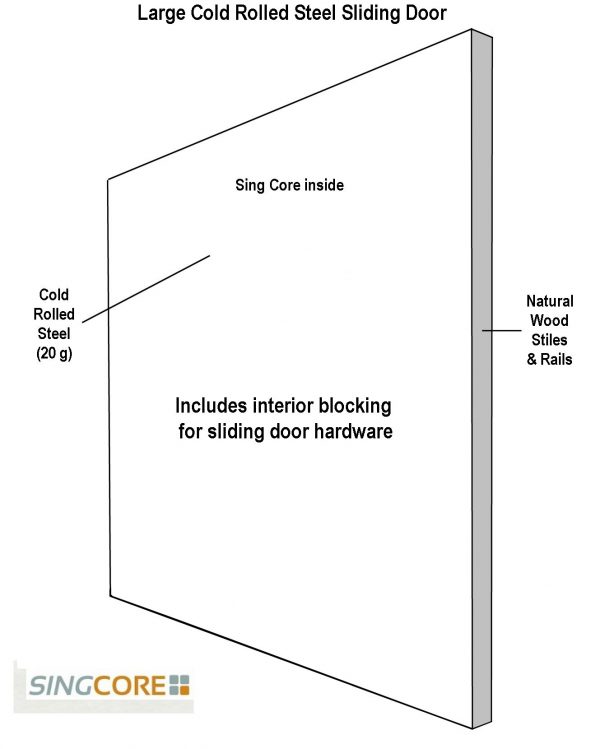

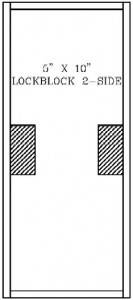

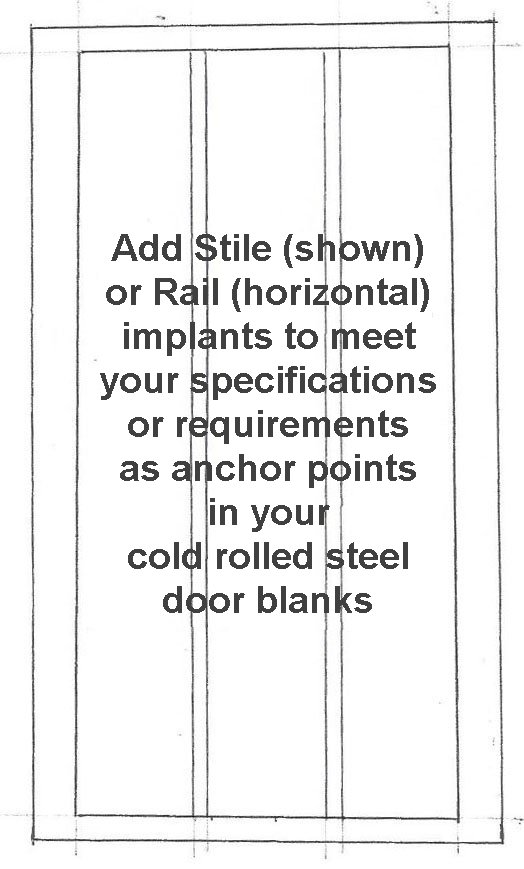

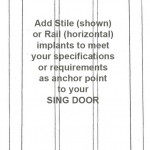

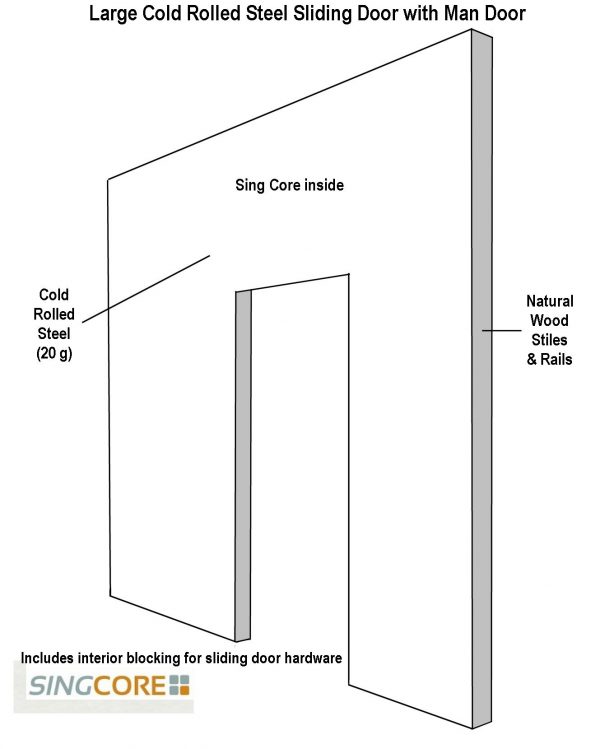

It’s very important that sliding doors be operable, especially in the arenas of bypass sliding doors or double sliding doors, and if your sliding metal doors are large in size, or in use as steel security doors, then other challenges must be taken into consideration in the architectural design and specification of your metal sliding doors.

Architectural specifications requiring Eco-friendly, lightweight and high strength metal sliding doors must be spec’d with, “Sing Core inside” to achieve these specifications. There are other benefits of having Sing Core inside your sliding metal doors, such as being pre-packed wall-to-wall with sound deadening and climate controlling insulation, and so much more.

Metal Automatic Sliding Door

If you’re dealing with a metal automatic sliding door, you can have virtually hassle-free installation and very little maintenance over time is your metal sliding doors are lightweight, high strength and warp-free. When sliding metal doors start to fail, bend or warp, it causes undue stress on both the automatic sliding door hardware as well as the structure that houses the hardware. This can cause expensive maintenance issues over time. Unless your sliding metal doors have Sing Core inside.

Warp-free Metal Sliding Doors

Only metal sliding doors with Sing Core inside can be guaranteed to remain warp-free for 50 years. This means your sliding metal doors can be guaranteed not to warp, bend, twist or otherwise fail for 50 years, including the full structure warranty of the door. Plus, the lightweight and high strength characteristics of the door, means less maintenance necessary over time, truly a breakthrough in architectural metal sliding door design specs.

Any Type of Metal Sliding Doors

We, at Sing Core, specialize in creating metal sliding doors that weigh a fraction of the weight of other metal sliding doors, as well as providing all the extra benefits of having Sing Core inside. Some of our most popular types of metal sliding doors include aluminium sliding doors and steel sliding doors, but we also provide the top metal sliding door manufacturers with the best sliding metal doors of different metals, which could include any available flat metal door skins. We make brass sliding doors, bronze sliding doors, and copper sliding doors, built to architectural specifications.

Aluminium Sliding Doors

In our support of architects and the custom metal door artisans, sliding door manufacturers, millworks and metal works companies who dare to deliver only the best aluminum sliding doors available. Sing aluminium sliding doors are made to the highest degree of accuracy and precision. Many types, styles and weights of aluminum are available, including anodized aluminum sliding doors, which are visually compelling when specified by the architect or custom aluminum sliding door manufacturer.

Steel Sliding Doors

Next up, our most popular metal sliding door are made with a variety of steels, to get that extra special, high-tech and ultra exclusive visual impact that can only be enjoyed if you have your cold rolled steel sliding doors, diamond plate steel sliding doors, galvanized steel sliding doors, hot rolled steel sliding doors, or stainless steel sliding doors manufactured to architectural specifications with Sing Core inside.

Metal Exterior Sliding Doors

Metal exterior doors can pose additional challenges, especially if they are large metal sliding doors that have one side 100% exposed to the elements. That’s just asking for trouble due to warp, but nor for your Sing metal exterior sliding doors, because they can be made not to warp. You also have the quandary of having one extreme environment on one side of the door and the other side facing the structure’s interior which also contributes to door warping. Now there is a solution to large metal exterior sliding doors, and the solution is having Sing Core inside.

Metal Kitchen Sliding Door

Besides exterior applications, interior metal sliding door applications include application specific metal sliding doors, such as metal kitchen sliding doors, and cold storage metal sliding doors. Whatever your application whether it is interior or exterior, Sing Core can help your favorite metal sliding door company to build the best metal sliding doors to your specifications and expectations.

-

Serving the Top Metal Sliding Door Manufacturers in the World

Sing Core provides professional Sing Core metal sliding door core to the top four metal sliding door manufacturers in the world (with billions of dollars in annual sliding metal doors) enabling them to create a high precision, high performance custom metal sliding door that can be Eco-friendly, made in the USA, lightweight and high strength sliding metal door, that can be guaranteed not to fail for 50 years.

See also: Metal Sliding Door Gallery

- Magnetic metal doors

- Multiple steel panels can be joined on site to create large stainless steel doors