When it comes to metal fabrication, one metal company is making an environmentally sustainable impact on the manner in which metal is handled in America today. Eco-friendly lightweight and high-strength metal panels are replacing solid metal sheets and metal honeycomb panels in a safe and responsible manner resulting in a patented metal fabrication method creating metal panels that weight a fraction of the weight of solid metal but are stronger than steel pound for pound.

When it comes to metal fabrication, one metal company is making an environmentally sustainable impact on the manner in which metal is handled in America today. Eco-friendly lightweight and high-strength metal panels are replacing solid metal sheets and metal honeycomb panels in a safe and responsible manner resulting in a patented metal fabrication method creating metal panels that weight a fraction of the weight of solid metal but are stronger than steel pound for pound.

Stainless steel has been problematic for steel fabricators to work with due to being a highly hazardous occupation, until now. Exposure to toxins and high-skilled trades-people make for an expensive end product. The extreme heavy weight of steel presents other problems in terms of safety on the job site and expensive transportation, installation and maintenance costs. Eco-friendly SingCore is the perfect solution for these problems.

Aluminum

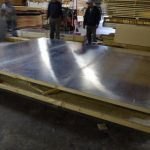

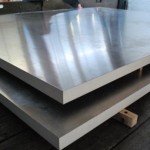

Aluminum is a lightweight metal and can be used in a variety of methods but needs a solid substrate or assorted framing to increase performance. While adequate for smaller projects, when the dimensions of the project expands so do the challenges. Sing Aluminum is the next level of high precision and performance due to its ability to offer:

Aluminum is a lightweight metal and can be used in a variety of methods but needs a solid substrate or assorted framing to increase performance. While adequate for smaller projects, when the dimensions of the project expands so do the challenges. Sing Aluminum is the next level of high precision and performance due to its ability to offer:

High Strength Aluminum

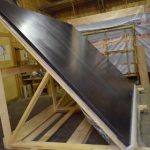

Where other aluminum panels fail due to unavoidable weakness, Sing Aluminum relies on a solid substrate comprised of natural vertical wood grain torsion box/recycled rigid foam composite to achieve strengths stronger than steel (660 PSI, and more) enabling long spans without deflection or compromise, even under loads.

High Precision Aluminum

Due to the extreme precision (+/- .006 in.) of the solid SingCore composite substrate, the resulting Aluminum material (available in aluminum panel or aluminum post and beam configurations) is extremely flat for high precision applications, while remaining lightweight and Eco-friendly.

Stainless Steel

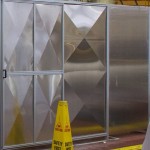

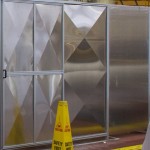

There is elegance to stainless steel that cannot be denied, though problems appear especially when dealing with projects of large size because stainless steel is so heavy. To reduce the weight, stainless steel plates can be sandwiched with some type of lightweight core to reduce the weight, but strength is compromised; that is, unless you have SingCore inside.

There is elegance to stainless steel that cannot be denied, though problems appear especially when dealing with projects of large size because stainless steel is so heavy. To reduce the weight, stainless steel plates can be sandwiched with some type of lightweight core to reduce the weight, but strength is compromised; that is, unless you have SingCore inside.

Lightweight Stainless Steel

Thanks to SingCore, you can achieve outstanding results using Sing Stainless Steel panels, weighing in at a fraction of the weight of solid stainless steel, but maintaining the structural integrity of solid steel. Even though the weight issue is addressed by using honeycomb or other type of core substrates, they fail under stress or strain. Only SingCore has the ability to deliver the strength of solid steel at a fraction of the weight, while maintaining its high precision.

Galvanized Steel

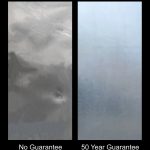

Long known for its ability to offer substantial weather resistance when exposed to the elements, galvanized steel is one of the most effective and long-lasting coating options for steel with a long history of success in all climates and weather conditions.

Long known for its ability to offer substantial weather resistance when exposed to the elements, galvanized steel is one of the most effective and long-lasting coating options for steel with a long history of success in all climates and weather conditions.

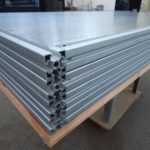

Super Strong Lightweight Galvanized Steel

Add to the long term success in exterior exposure, the lightweight and high strength of sandwiching galvanized steel around patented SingCore, and you have a panel that is impervious to the elements that could be interconnected using cam lock technology or other methods to build a modular exterior building or shelter in minutes, besides other applications.

You could build modular Sing galvanized steel panel components that could be guaranteed fail-free for 50 years.

Cold Rolled Steel

Cold Rolled Steel

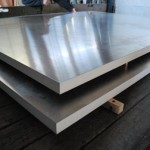

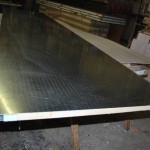

Cold rolled steel is readily available in flat sheets and perfect for creating high precision and high performance custom steel doors when applied to patented SingCore. Cold rolled steel is one of the most popular steel surface materials in making Sing steel doors, which are steel doors with SingCore inside.

Besides doors, other popular cold rolled steel products include cold rolled steel panels, posts and beams with SingCore inside for lightweight high strength high precision and long life performance over time, unlike any other cold rolled steel substrate known.

Hot Rolled Steel

Hot Rolled Steel

Hot rolled steel is similar to cold rolled steel, though is less strong than cold rolled steel. This can be overcome by crating high precision and extremely strong hot rolled steel panels with SingCore inside.

We are seeing an increase in hot rolled steel in both wall hot rolled steel panels and hot rolled steel doors due to the industrial look of the heat signatures that are unique characteristics of hot rolled steel and often part of the aesthetic design of the architect or designer of the project at hand.

Hot Rolled Steel Large Sliding Doors

- Hot rolled steel

- 21 ft tall metal ivot door

- durable 50 year guarantee

- Metal with SingCore inside

- Eco friendly cold rolled steel

- Metal strength demo

- Eco friendly closed edge

- Sliding metal door panels

- Galvanized Steel + T Slot

- 20 ft span galvanized demo

- Hot rolled steel accordion

- Hot rolled steel large doors

- Eco friendly metal edges

- Lightweight metal bench