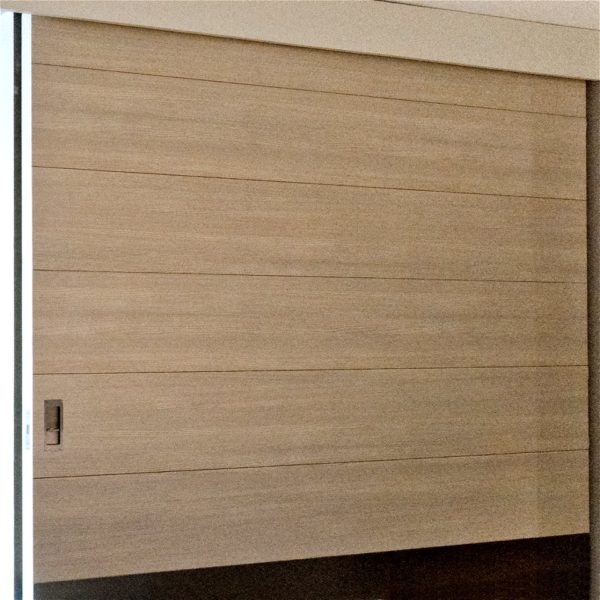

One of the most unique design elements in contemporary architecture and design includes the use of wood veneer as an artistic outlet and creative expression as an alternative to solid wood. Doing so increases unique design characteristics exponentially, due to nearly unlimited matching options to create a one-of-a-kind wood grain Objet d’art as a feature presentation piece. Not only is wood veneer just as beautiful as solid wood, but it is a green approach to modern building and design due to the responsible use of natural wood grains.

High-end millworks who specialize in the most exclusive veneer work for the least cost inhibited clientele must have not only the artistic eye but have a keen sense of detail and a great deal of expertise to create one of these masterpieces flawlessly, and they have many methods that they use to assemble and manufacture the veneer while maintaining strength, precision, and to guarantee the overall performance over time for ultimate customer satisfaction.

Woodworkers who take on veneer projects must use a substrate to apply the veneer to. Particleboard and plywood are the most common for general use though they may not meet the needs of more discerning clients. Cabinet-grade plywood and MDO are considered upgrades to particleboard and standard-grade ply. And most upscale millworks prefer the smooth surface of MDF to adhere their veneer to.

When using thin veneers, the smallest imperfections in the substrate are magnified on the surface area, so most high-quality jobs are cross-banded for a more satisfactory and natural overall appearance.

In basic cabinetry and furniture making, these are reasonable solutions for substrate due to there being plenty of reinforcement and supporting structure throughout the piece.

Architects and designers who have experience with creating veneer art realize that there are limitations when using veneer designs when factoring in size. If a piece features a span greater than 8 feet in any direction, many challenges begin to arise when trying to manifest the artist’s vision in the real world.

The most common obstacles to creating large spanning veneer projects, like large doors or conference room tables, are heavy weight, decreased dimensional stability, and increase surface flaws.

Surface flaws become apparent anywhere there may be a seam in the substrate material. Carefully pre-finishing and treating the surface material will conceal the seams upon creation of the piece, but any movement in the piece may expose the seam which will become immediately apparent on the surface area and may lead to delamination of the surface material, resulting in product failure.

The country’s biggest and best veneer artists and architectural door manufacturers know that there is an alternative for veneer projects of large to massive size, and for their most important projects they specify Sing Core as the best wood veneer substrate.

The Best Wood Veneer Substrate

For years, since inventor Peter Sing introduced his patented Sing Core to millworks and high-end large door manufacturers, his veneer substrate has been the flawless answer to the questions and challenges facing architects and designers who have overcome the obstacles to long spanning veneer designs.

This unique hybrid composite core consists of a small (2 to 3 inch) metric torsion box made of vertical wood grain fiber, where the cell voids are filled with rigid foam sandwiched between smooth MDF faces for an incredibly lightweight and dimensionally stable high precision base for veneering.

Sing’s core is so substantial that it sports tolerances of +/- .006 in. and is guaranteed not to warp, bend twist, or otherwise fail (including delamination) for 50 years.

With such a high-precision non-warping substrate, seams will not fail due to movement, and the longevity of the beauty of your creation is preserved over time.

This is the answer that the millworks and veneer shops have been looking for to address the inherent problems associate with large spanning veneer projects for clients who demand the best and will not settle for less.

Therefore, Sing Core is considered the best veneer substrate in the world, and why it can be found inside the most expensive and oversized veneer artistry in multi-million-dollar estates, corporate and industrial projects, museums, and ultra-chic installations.

If your veneer project requires flawless excellence, high precision, and long fail-free service life, you should use the best veneer substrate, so that you and your clients can rest assured because there is Sing Core inside.